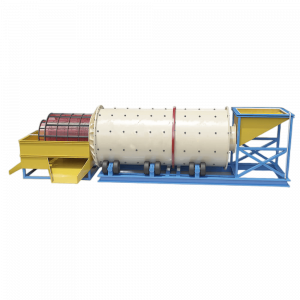

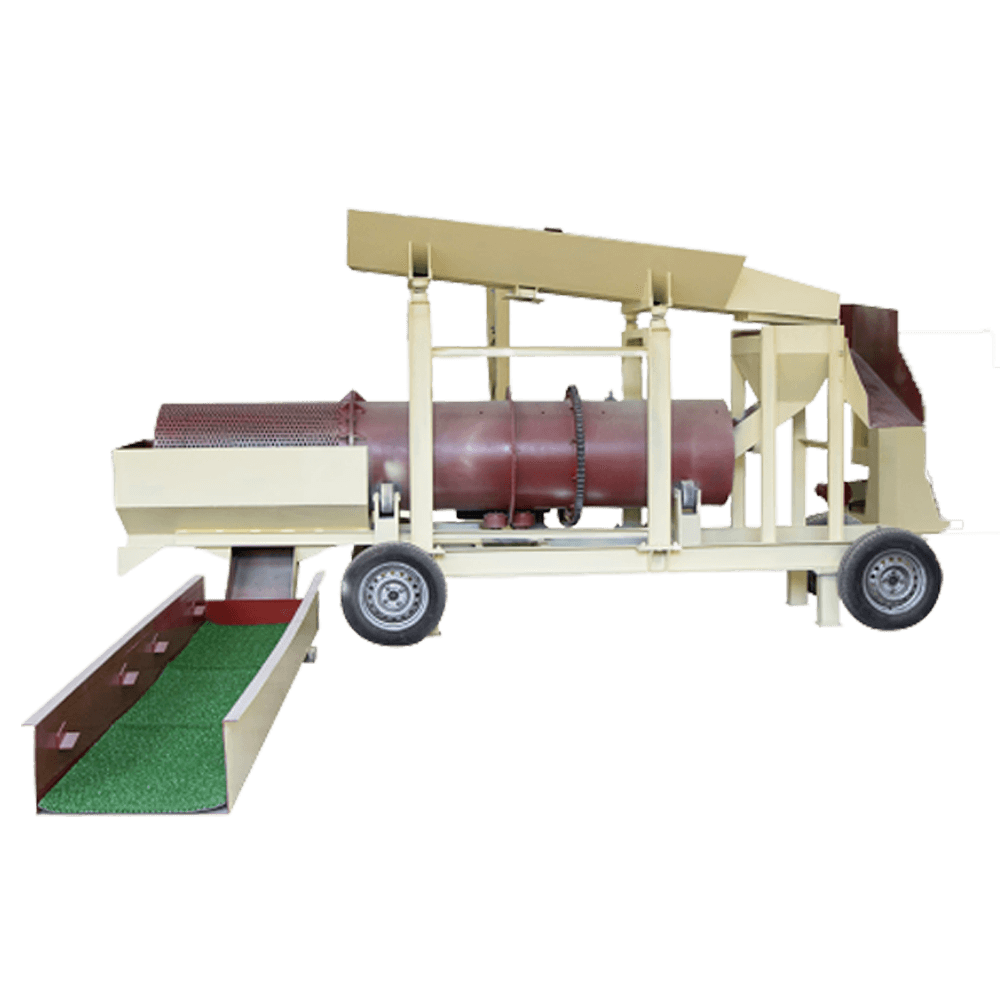

portable trommel screen

Capacity: 1-200TPH

Feeding size: ≤80-100mm

Feeding density: 0-50%

Application: Sand and gravel aggregate and ore classifying, screening, washing, processing; gold, diamond ore, silica sand, manganese ore, iron ore, quartz sand and other ore with low mud content.

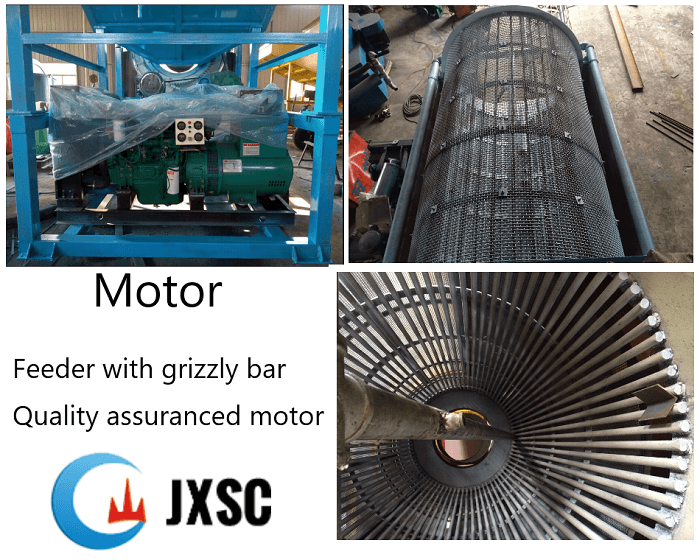

Products display

Overview

Introduction: Trommel screens are one of the oldest screening devices, their structures are very simple but yet with high sorting accuracy and efficiency. The gold trommel can washing and screening material from 55 mm down to 6 mm, and even smaller sizes can be handled under wet screening conditions.

Trommels remain widely used in some screening operation, including aggregate screening plants and the screening of mill discharge streams. They are also used for wet-scrubbing ores, such as Bauxite, alluvial gold, diamond ores and etc. Usually combined with a gold sluice box to form a one-stop small gold wash plant. JXSC support customized fixed and mobile/portable trommel screens.

Advantages Of Trommel screen

- The screening efficiency is high, the screen holes are not easily blocked, and the operation is smooth.

- Simple structure and easy maintenance.

- The portable trommel screen using special screens, high screening efficiency and longer service life can be achieved.

- During the operation of the equipment, the noise generated by the materials and the rotating screen is completely isolated by the sealed dust cover, which eliminates the flying dust during the screening process and provides an excellent operating environment; the noise cannot be transmitted to the outside of the equipment, thereby reducing the equipment noise.

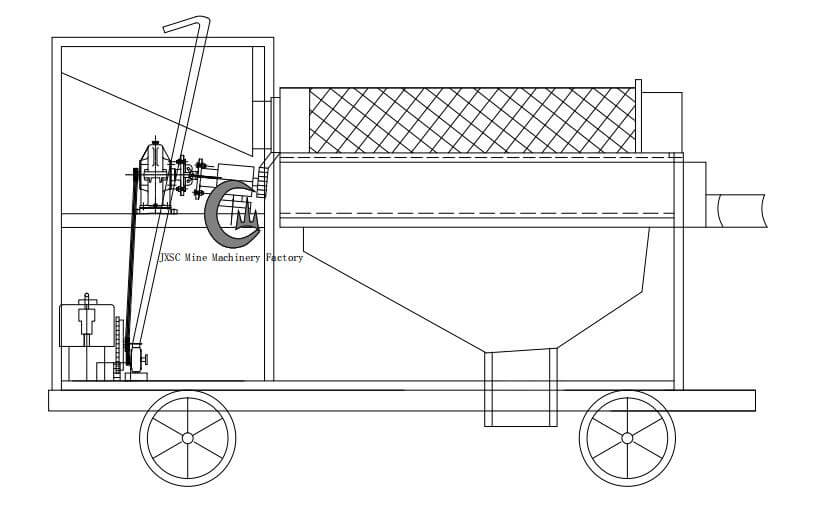

Working principle Of portable trommel screen

Trommels are installed on a small angle to the horizontal or use a series of internal baffles to transport material along with the cylinder.

When the feeding material enters the roller trommel, due to the tilt and rotation of the trommel, the material on the screen surface is turned and rolled, so that the qualified material (under-screen product) is discharged through the outlet at the bottom of the rear end of the roller, and the unqualified material (upper-screen product) is discharged through the discharge port at the rear of the trommel.

models & specifications

Model | Screen Size(mm) | Feeding Size(mm) | Drum Dia (mm) | Drum length (mm) | Process Capacity(t/h) |

|

GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |

The drum body of the drum screen is generally divided into several sections, depending on the specific situation, the screen holes are arranged from small to large, and the screen hole diameter on each section is the same.

In order to improve the sorting accuracy and avoid the situation where small particles are screened out in the large-aperture screen section, the feeding materials must be fully turned in the trommel screen, and the movement speed of those materials cannot be too fast.

Generally, the inner wall of the trommel is equipped with a flex plate. Its role is to raise the feeding particles so that particles with different sizes get as many opportunities as possible to contact the sieve hole.

If the hole diameter meets the requirements, the particles can pass through the sieve and get sorted.

Also, the trommel screen generally has a relatively strict installation angle, usually, this angle is 5°. Of course, under actual circumstances, it can be adjusted as needed.

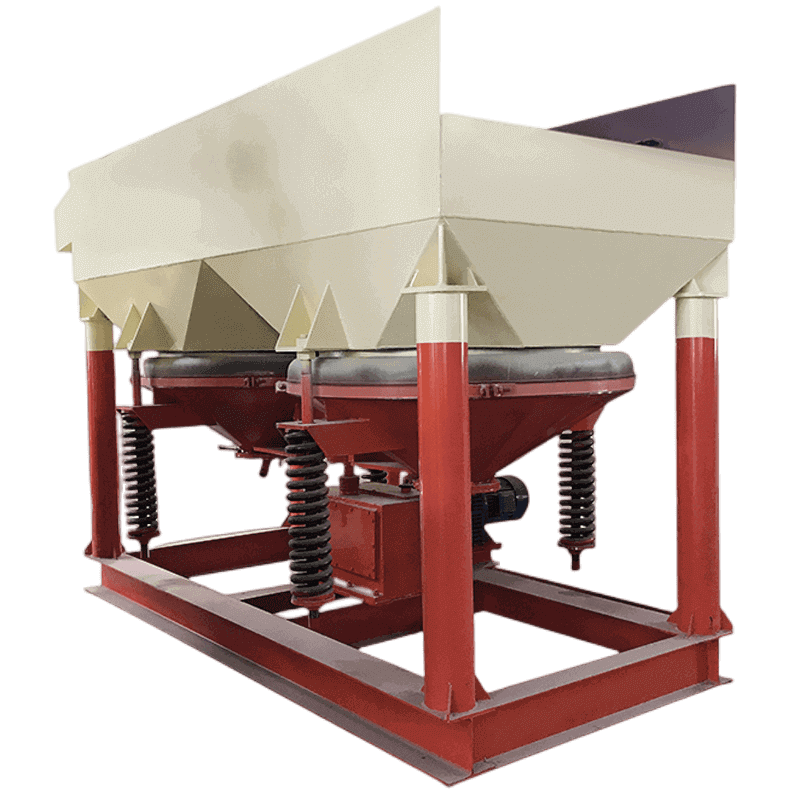

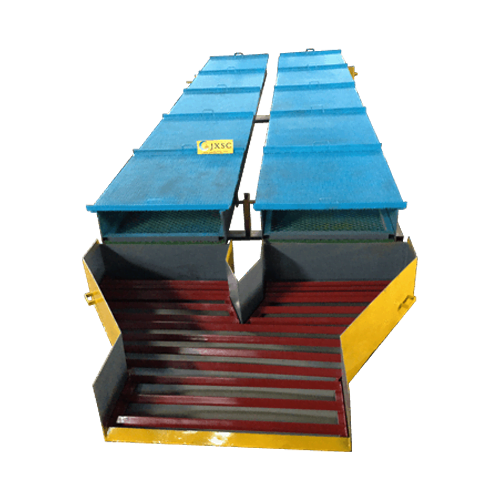

Related Products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.