200TPH Alluvial Gold Washing Plant In Ghana

We guarantee the high quality machine in the mineral processing industry, established in 35 years of experience

Project Info

1. Raw ore: alluvial gold with sticky mud

2. Capacity: 200TPH

3. Input size: 200mm

4. Output size : 0-6mm, 6-12mm

Process

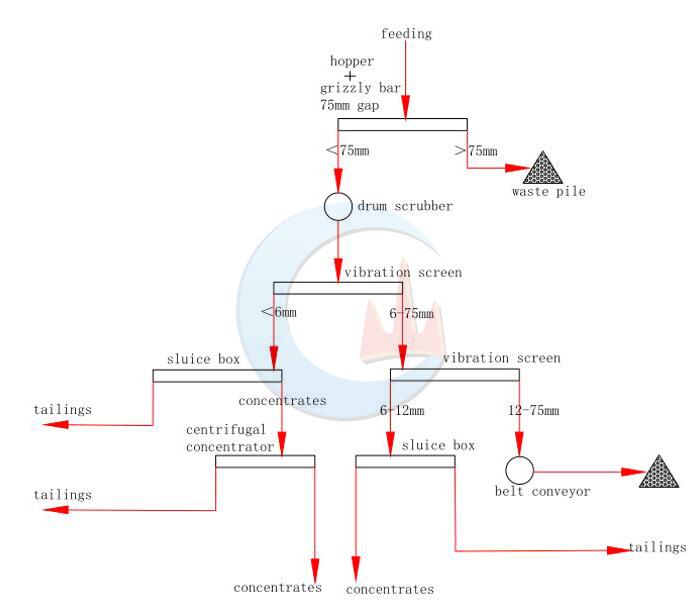

Washing – Screening – Gravity separation

process flow

- Mining field: Accra, Ghana, plain, no height difference is allowed, and the ground cannot be dug too deep

- Raw ore information: The amount of sticky mud is relatively large. When feeding, a high-pressure water spray gun is required to disperse the material. The gold particle size is 0-12mm, and the maximum feeding particle size of the raw ore is 150-200mm.

- Customer request: After ore washing, gold particles of 0-6mm and 6-12mm are recovered respectively. The process is required to be as simple as possible, easy to operate, and low energy consumption.

1. Washing stage: Trommel scrubber

The loader feeds the material to the hopper, the high-pressure water spray gun sprays water to the silo, and the material is fed to the vibrating feeder. The grid screened out +75mm, the belt conveyor transported +75mm of waste, and the 0-75mm guide chute fed into the washing machine.

The trommel scrubber does not have a screen, and the material is discharged into a high-frequency vibrating screen (the first 6mm sieve, the second 12mm sieve),

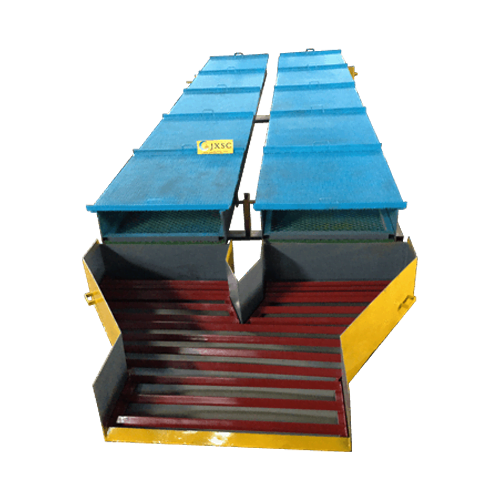

2. Screening stage: Vibrating screen

The first vibrating screen discharges 0-6mm into 4 rows of gold chutes (2 sets * 6 meters in each row) to recover 0-6mm gold, 6-75mm goes into the second vibrating screen,

6-12mm into 2 rows of gold chutes (2 sets * 6 meters) to recover 6-12mm gold, and +12mm waste belt conveyor to transport it away.

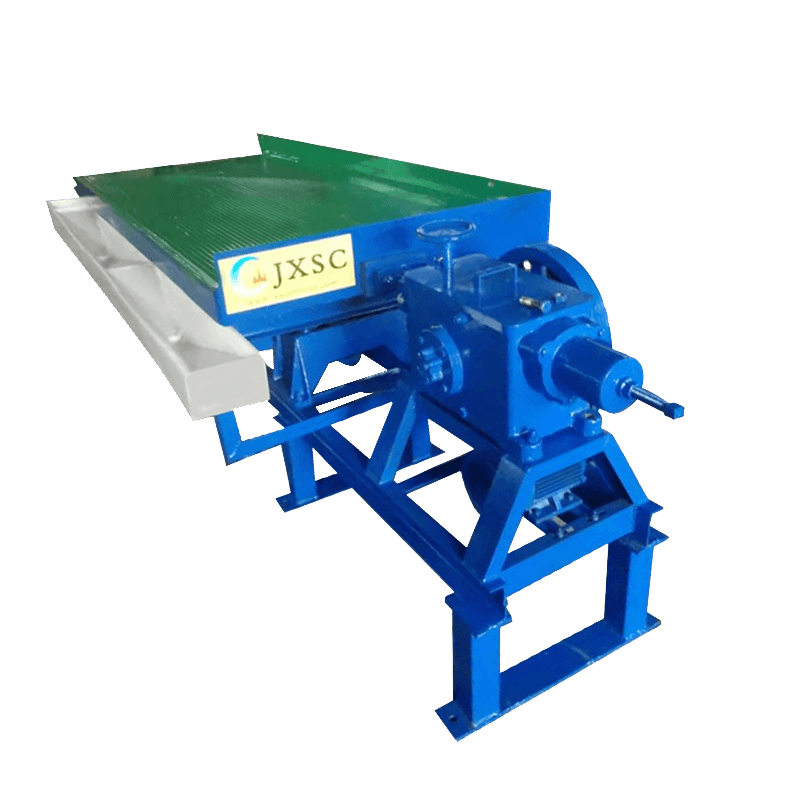

3. Gravity separation: Jig separator, shaking tables, sluice box

All the concentrate washed out of the gold chute goes into the jig machine, the 0-2mm concentrate is screened and then put on the shaker, and the +2mm concentrate on the screen is cleaned out manually on a regular basis. (Jig concentrator and shaking tables are installed indoors by customers to prevent workers from stealing gold)

Process Site

Main Equipment

Product name | Model No. |

Vibrating feeder | 6000*1200mm |

Trommel scrubber (without screen) | 2.2m*5m |

2 sets high frequency vibrating screen | JXSC-2045, 6mm, 12mm sieve hole |

2 sets belt conveyor | 650*15m |

1 set small shaking table | LY2100*1050 |

2 sets large water pumps | 12/10 inches, 55KW |

1 set high pressure water pump | 6 inches |

15 sets gold sluice box | With cover + metal mesh |

Other Cases

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.