What is a rotary scrubber?

In the mining industry, the rotary scrubber is the often used mineral washing machine for upgrading or increasing the cleanliness of mineral ore or rocks that only contain a lighter, loamy type of clay or dirt and dust. The rotary scrubber works simply by spinning the scrubber inside slowly, and churning the fines and oversize and adding water together, vigorously breaking up the soil matrix as well as liberating the target mineral from tough clay, and rock, which is similar to a washing machine, but with a much more big size.

The sticky clay after washing with a rotary scrubber can add more economic value to the final product or help with further downstream processing equipment, such as centrifugal concentrator, spiral chute, jig, etc.

Here are some characteristics and advantages of rotary scrubber

- Designed to break up alluvial gravels, clays, and sand;

- High capacity and high scrubbing efficiency;

- The long drum of the scrubber retains material for longer, more vigorous washing for complete separation;

- Heavy-duty bearing, gear, and roller;

- Wearable screen at the exit of the drum for screening;

- One high output electrical motor driving a gear system providing efficient torque;

- Adjustable rotary speed;

- The water with high pressure flushed the inwall of drum;

- Bigger feeding size, the max material feeding size can be up to 230mm.

Rotary scrubber for gold and diamond mining

Due to the above advantages of rotary scrubber washer, and the stability characteristics of gold and diamond, it makes the rotary scrubber as the ideal washing machine for placer gold, diamond wash process.

Also, there are many equipment options available for washing, so when considering the correct equipment and process flow for your application, you must first take into account the type of contamination you wish to remove and the properties of the waste material.

Is the contaminate a tough, fine-grained, tacky clay that needs the aggressive scrubbing action of a Log Washer? Or is the contaminate a lighter, loamy type clay or dirt and dust that can be removed with either a Coarse Material Screw Washer or a Rotary Scrubber? Once this has been determined, then the proper equipment for the application can be selected based on feed size and capacity, among other variables that need to be considered.

How does rotary scrubber works

It is preferable that the –0.25” (6mm) fines fraction be removed from the feed before being introduced to the scrubber. This can be accomplished through traditional screening methods or by adding a desanding section to the scrubber to help remove a portion of the fines. By doing so, you are allowing the scrubbing action to be more vigorous as opposed to the fines fraction cushioning the scrubbing action.

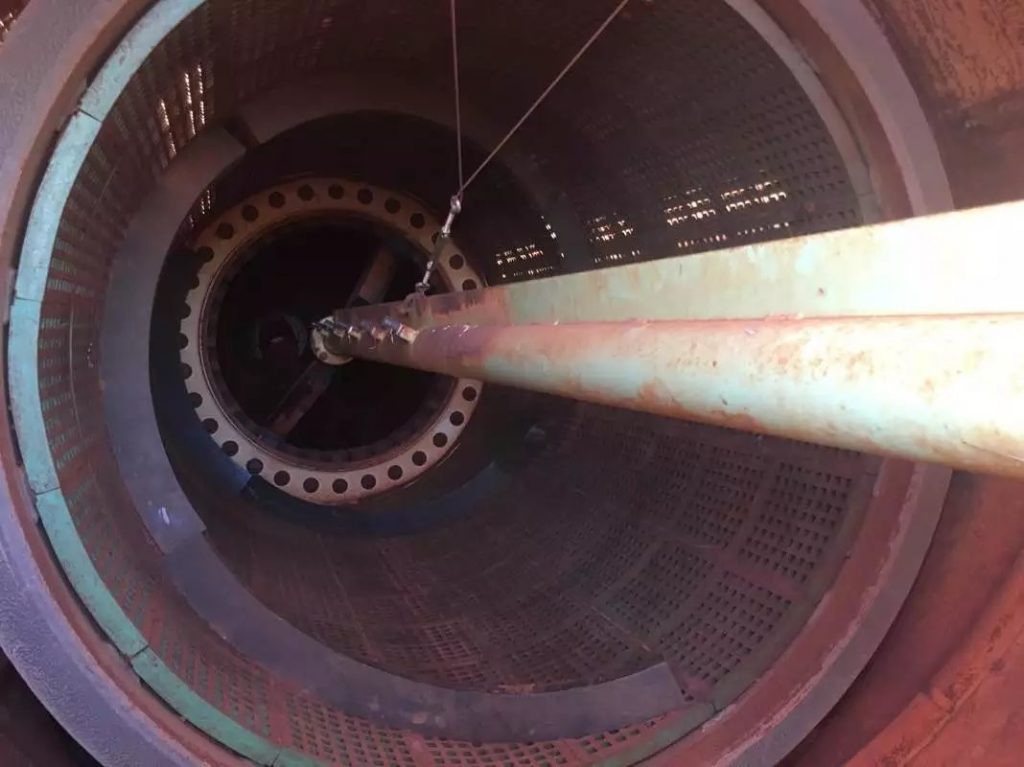

The feed solids and water are introduced in the feed chute of the Rotary Scrubber. The rotating drum (which is provided with lifter bars), in conjunction with centrifugal force, carries the slurried material up the side of the drum until approximately the 11 o’clock position, where it releases, cascades, and tumbles back down to the cylinder bottom, where the process begins again. This process continues as the slurry is carried the length of the cylinder. The action helps break down softer materials and dissolve the dirt, loam, and other foreign materials into a solution.

As the slurry exits the Rotary Scrubber, it is recommended that the material pass across a rinse or sizing screen. In certain applications, the Rotary Scrubber can be supplied with a trommel screen extension and an internal spray bar for making a rough sizing cut. This extension can be either a single- or double-shell design to allow for the creation of multiple product-size cuts. This screen media can be made from abrasion-resistant, perforated rolled plate, rubber, or urethane screen panels. Depending on the cut point and capacity, a trommel extension may not be suited for accurate product separation. Capacities of up to 2,500 tph can be achieved in a single Rotary Scrubber.

Once this process has been completed, the washed product is ready for further downstream crushing or sizing.