200TPH Alluvial Gold Washing Plant In Ghana

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info

1. Raw ore: alluvial gold with sticky mud

2. Capacity: 200TPH

3. Input size: 200mm

4. Output size : 0-6mm, 6-12mm

Process

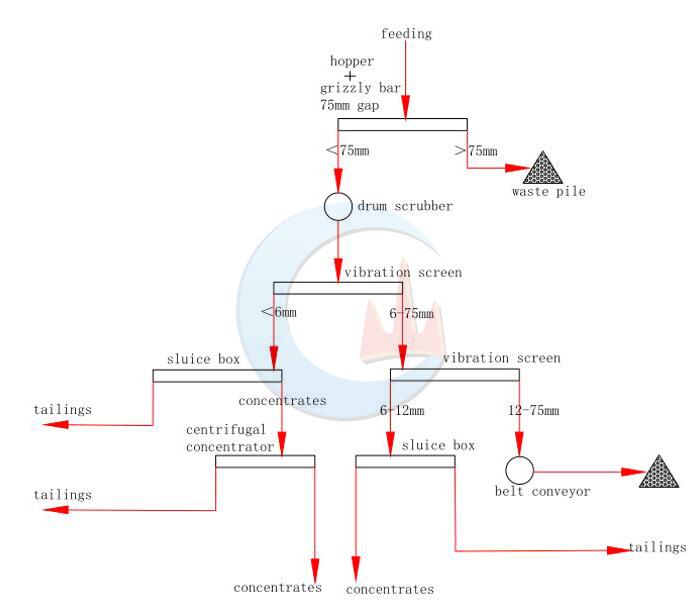

Washing – Screening – Gravity separation

process flow

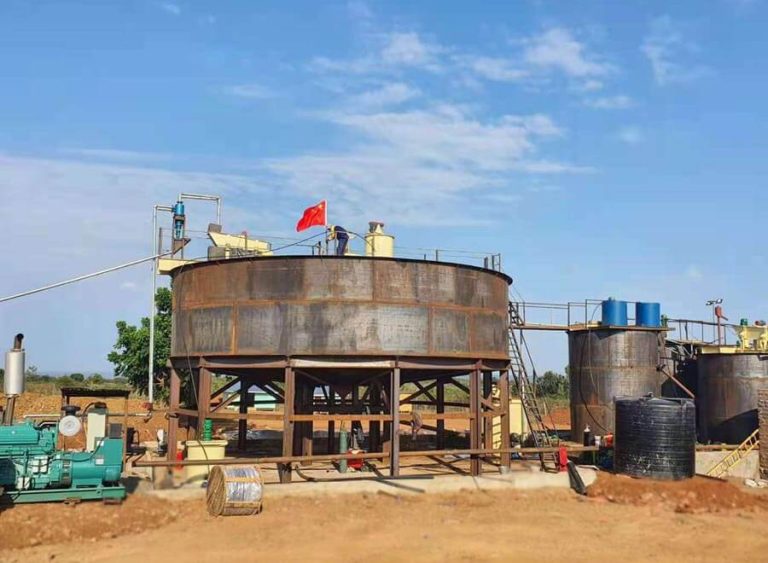

200TPH Alluvial Gold Washing Plant

- Mining field: Accra, Ghana, plain, no height difference is allowed, and the ground cannot be dug too deep

- Raw ore information: The amount of sticky mud is relatively large. When feeding, a high-pressure water spray gun is required to disperse the material. The gold particle size is 0-12mm, and the maximum feeding particle size of the raw ore is 150-200mm.

- Customer request: After ore washing, gold particles of 0-6mm and 6-12mm are recovered respectively. The process is required to be as simple as possible, easy to operate, and low energy consumption.

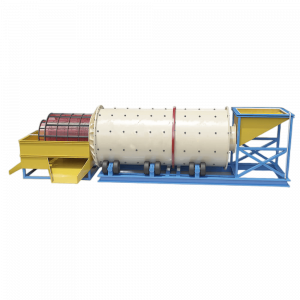

1. Washing stage: Trommel scrubber

The loader feeds the material to the hopper, the high-pressure water spray gun sprays water to the silo, and the material is fed to the vibrating feeder. The grid screened out +75mm, the belt conveyor transported +75mm of waste, and the 0-75mm guide chute fed into the washing machine.

The trommel scrubber does not have a screen, and the material is discharged into a high-frequency vibrating screen (the first 6mm sieve, the second 12mm sieve),

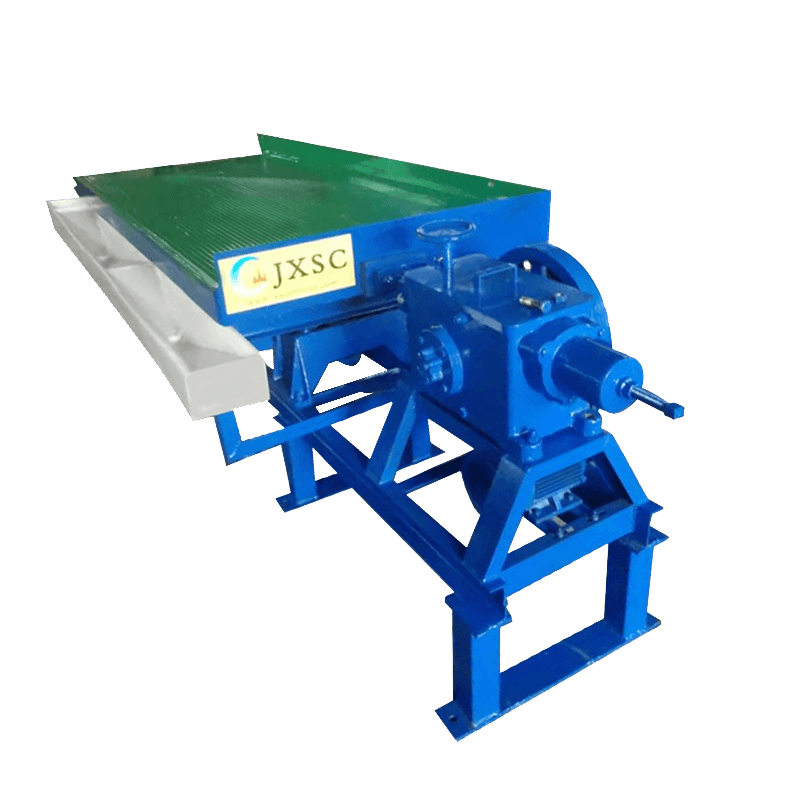

2. Screening stage: Vibrating screen

The first vibrating screen discharges 0-6mm into 4 rows of gold chutes (2 sets * 6 meters in each row) to recover 0-6mm gold, 6-75mm goes into the second vibrating screen,

6-12mm into 2 rows of gold chutes (2 sets * 6 meters) to recover 6-12mm gold, and +12mm waste belt conveyor to transport it away.

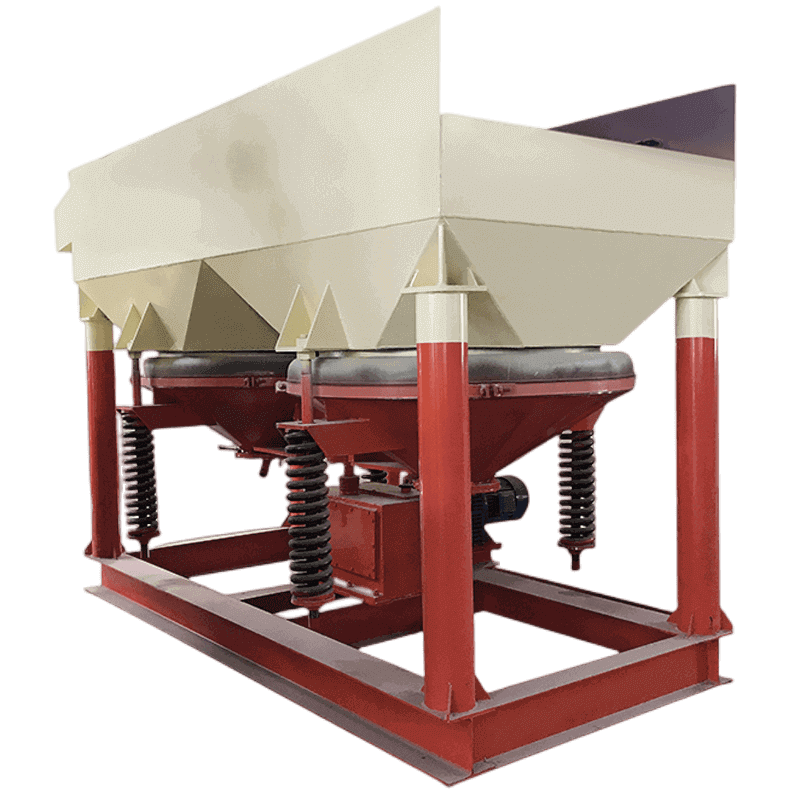

3. Gravity separation: Jig separator, shaking tables, sluice box

All the concentrate washed out of the gold chute goes into the jig machine, the 0-2mm concentrate is screened and then put on the shaker, and the +2mm concentrate on the screen is cleaned out manually on a regular basis. (Jig concentrator and shaking tables are installed indoors by customers to prevent workers from stealing gold)

This complete alluvial gold washing plant has a high recovery rate and good overall economic benefits. Contact us for customized gold processing solutions and equipment, 100% factory prices!

Process Site

200TPH Alluvial Gold Washing Site

1. Synergistic Process Integration of Efficient Cleaning and High Recovery: The drum scrubber effectively cleans large ore particles. The final centrifugal concentrator further increases gold recovery to 95%-98%, significantly reducing the risk of gold loss.

2. High Stability and Low Maintenance Cost Design: The core components of the equipment (motor, bearings, and screen) are made of durable materials. For example, the drum lining can be selected from rubber or polyurethane to adapt to different mineral characteristics. The structure is made of high-hardness carbon steel and high-manganese steel wire mesh, which is highly impact-resistant.

3. Flexible Adaptability and Rapid Deployment: The process supports customized production capacities from 1 to 300 TPH, allowing the processing scale to be adjusted according to the actual needs of the mine. The equipment design is both fixed and mobile, adapting to the terrain conditions of various mining areas in Ghana (such as Accra and Kumasi).

Based on its in-depth understanding of the characteristics of African gold mine resources, JXSC provides full alluvial gold washing plant customization services from process design to equipment implementation. Targeted to the unique characteristics of alluvial gold deposits in regions like Ghana, we can customize key parameters such as drum scrubbers size, gravity separation equipment combinations (e.g., chute + centrifugal concentrator), and power systems to meet production capacity requirements of 50-300 TPH. Contact us for complete (rock gold/alluvial gold) gold processing solutions, enabling efficient and high recovery plants.

Main Equipment

Product name | Model No. |

Vibrating feeder | 6000*1200mm |

Trommel scrubber (without screen) | 2.2m*5m |

2 sets high frequency vibrating screen | JXSC-2045, 6mm, 12mm sieve hole |

2 sets belt conveyor | 650*15m |

1 set small shaking table | LY2100*1050 |

2 sets large water pumps | 12/10 inches, 55KW |

1 set high pressure water pump | 6 inches |

15 sets gold sluice box | With cover + metal mesh |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.