80TPH Tantalum Beneficiation Plant In Rwanda

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience

Project Info

1. Raw ore: alluvial tantalum ore

2. Capacity: 80TPH

3. Location: Rwanda

4. Input size: > 60mm

Process

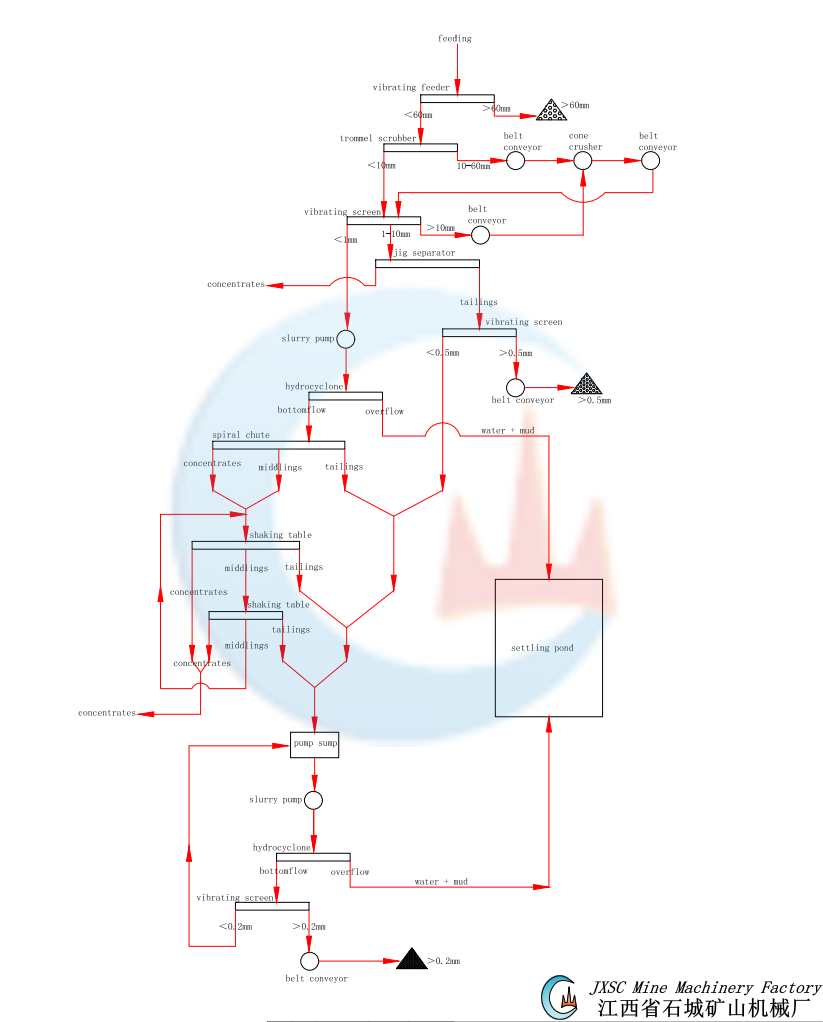

Feeding – Washing – Crushing – Screening – Gravity separation – tailings processing

80TPH Tantalum Beneficiation Process Plant

Tantalum-niobium ores are mostly placer ores with simple properties and single composition. Generally, the content of mud is high and the clay is strong.

80TPH tantalum beneficiation plant flow details:

1. Feeding & Washing: vibrating feeder, trommel scrubber

The material smaller than 60mm enters the trommel scrubber through the vibrating feeder to clean the silt and other impurities of the raw ore. Sieve the material into 0-10mm, 10-60mm material.

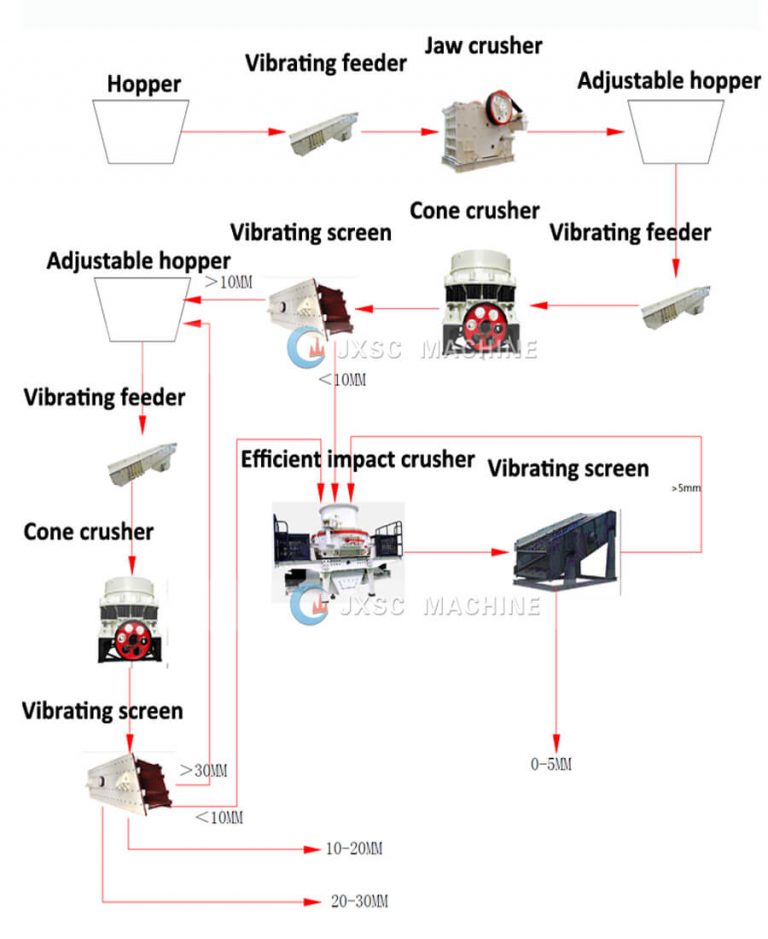

2. Crushing & Screening: cone crusher, vibrating screen

Among them, the 0-10mm material directly enters the vibrating screen. 10-60mm material is transported to the cone crusher by belt conveyor for crushing to less than 10mm, and then transported to the same vibrating screen by belt conveyor for screening. Screened into 0-1mm, 1-10mm, more than 10mm these three kinds of material specifications.

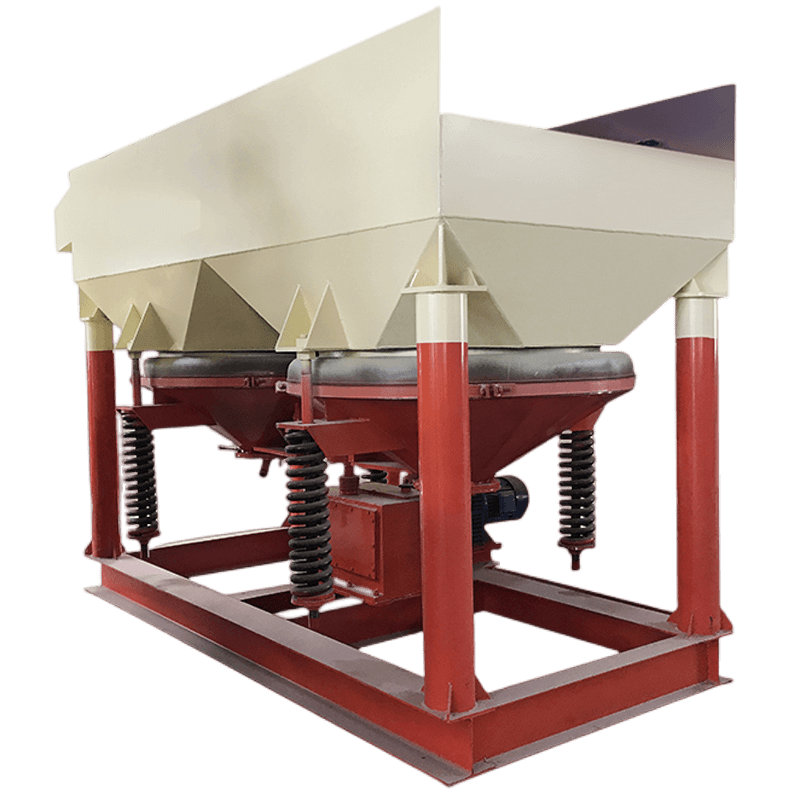

3. Classifying & Separation: hydrocyclone, jig seaprator

The o-1mm material is directly transported to the hydrocyclone by a sand pump for grading and dehydration, and the overflowing muddy water enters the pool. Materials more than 10mm are returned to the cone crusher for secondary crushing, and the next step is carried out after reaching the qualified particle size. The 1-10mm material enters the jig machine for separation to obtain tantalum concentrate, the tailings of the jig machine enter the vibrating screen for screening, and the material larger than 0.5mm is transported to the side by a belt conveyor.

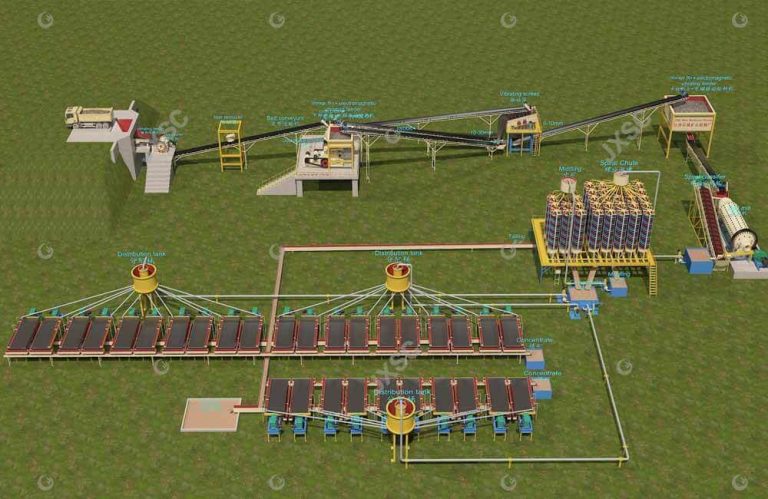

4. Gravity separation: spiral chutes, shaking tables

The underflow of the cyclone enters the spiral chute for gravity separation, while the concentrate and medium ore enter the two-stage shaking table for separation to improve the grade of the concentrate.

5. Tailings treatment

The tailings and materials less than 0.5mm in the spiral chutes and shaker table are transported to the hydrocyclone by a sand pump for desliming and mediation, the underflow is screened, and the overflow muddy water enters the pool.

JXSC provide a full set of tantalum beneficiation processes, equipment, and installation services. We support customized tantalum benefication equipment and have rich practical experience. If you have any questions about tantalum-niobium ore dressing flow and machines, please contact us at any time, experienced technical personnel will answer all questions for you.

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.