Arc plate electrostatic separator

Capacity: 1-3 T/H

Feeding size: 0-3 MM

Application: Arc plate electrostatic separator is widely used in extracting zircon, rutile, ilmenite, and monazite from beach sand; separating tinstone, tantalum-niobium minerals, and high-phosphate rutile. It mainly upgrades conductive mineral concentrates (e.g., tin, iron ore) and purifies non-conductive minerals.

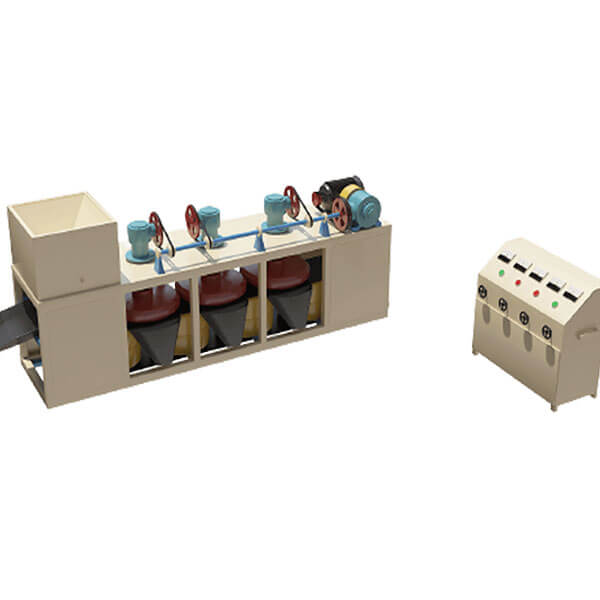

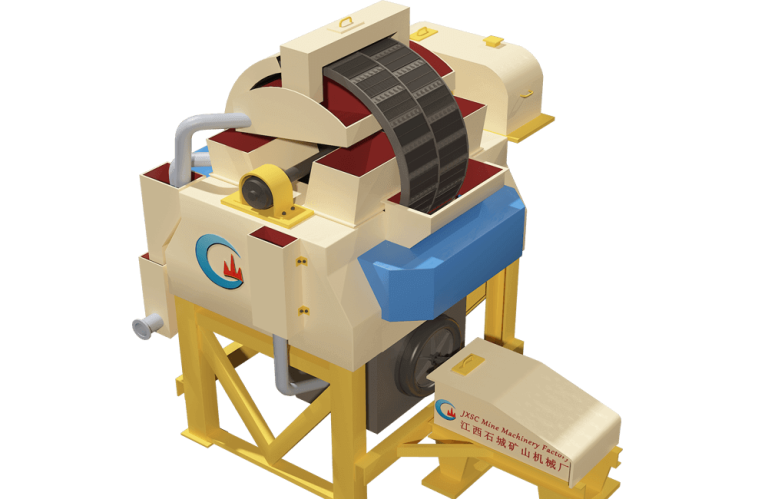

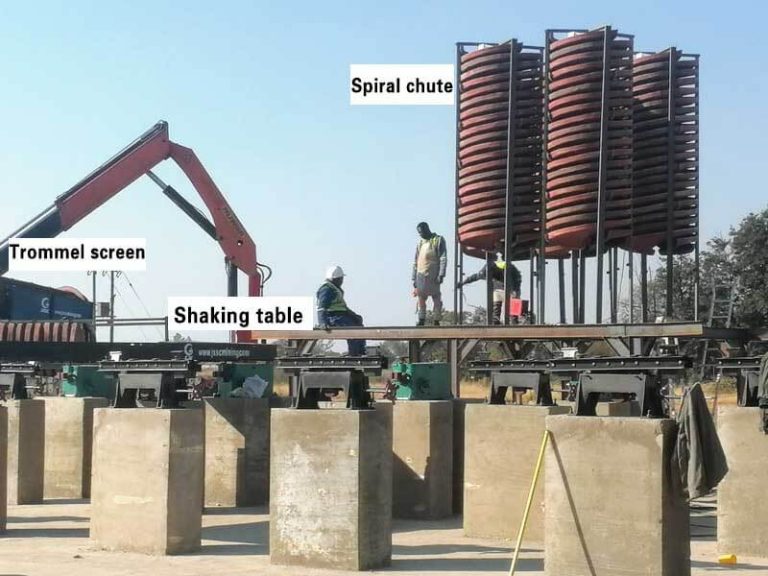

Products display

introduction Of Arc plate electrostatic separator

Arc plate electrostatic concentrator is an efficient dry beneficiation equipment designed to separate conductive and non-conductive minerals based on the difference in conductivity. The equipment combines corona field and electrostatic field to achieve precise sorting and is widely used in mining and mineral processing industries. Through the synergistic effect of high-voltage corona field and electrostatic field, conductive minerals (such as ilmenite and magnetite) and non-conductive minerals (such as zircon and quartz) can be accurately separated. It is mainly used to improve the grade of minerals, reduce subsequent processing costs, and support multi-mineral synergistic sorting, providing a key purification link for the mineral processing production line. It is especially suitable for purifying minerals such as rutile, zircon, ilmenite and cassiterite from beach sands and ore deposits.

Key functions

Our arc plate electrostatic concentrator is an important mineral separation equipment that can be used in a variety of mineral processing scenarios:

- Zircon sand processing: zircon concentrate purity reaches 98%.

- Rutile beneficiation: recovery rate is increased by 35% compared with traditional methods.

- Beach sand mineral separation: ilmenite, rutile, zircon and monazite are separated simultaneously from coastal deposits.

Arc plate electrostatic concentrators are usually integrated with magnetic separators, spiral concentrators, and shaking tables to form a complete mineral processing line to improve the total recovery rate. JXSC supports customizable arc plate and two or four-roller type electrostatic separators equipped with high-voltage generators to meet various beneficiation needs.

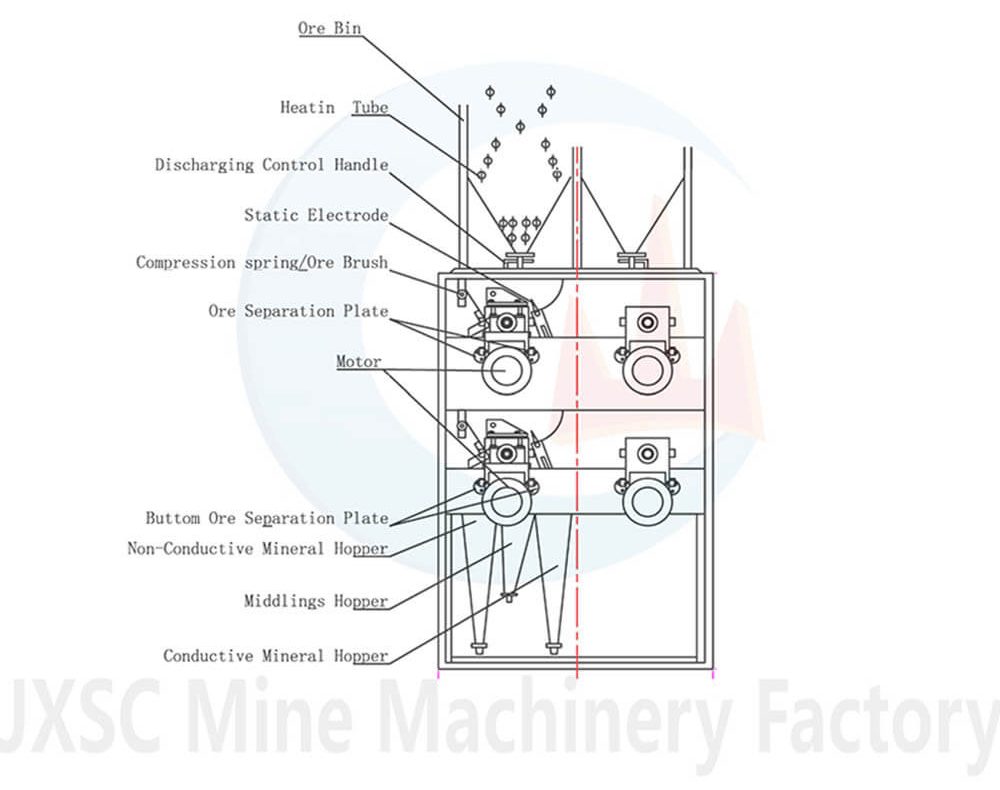

structure & working principle of Arc plate electrostatic separator

The arc plate electrostatic separator is mainly composed of a feeding device, an arc electrode, a separation chamber, a collecting device, a control system or a vibrator (optional).

The working principle of the arc plate electrostatic concentrator is based on the difference in material conductivity. When minerals enter the high voltage electric field, they are subjected to the combined effects of Coulomb force, centrifugal force and gravity. The complex interaction between the corona electrode (electrode wire) and the polarized electrode tube, coupled with the rotating drum, creates different movement trajectories for conductive and non-conductive particles.

Conductive minerals (such as ilmenite, magnetite, cassiterite and native gold) tend to accept charges and deviate to the collection plate. In contrast, non-conductive minerals (such as quartz, zircon, feldspar, calcite, scheelite and silicate minerals) follow different paths due to their poor conductivity. This difference in trajectory enables the efficient separation and enrichment of valuable minerals.

why choose JXSC Arc plate electrostatic separator

Features & advantages Of Arc plate electrostatic separator

1. High sorting efficiency: The concentration efficiency of conductive minerals is as high as 95%+, which is ideal for low-grade or complex ores.

2. Versatility: It can handle feed sizes of 0-3 mm and adapt to various mineral sorting by adjusting the voltage.

Automation and safety: Equipped with PLC control system, overload protection and advanced safety functions to ensure stable operation.

3. Durability: The structure is sturdy and the core components (motor, high-voltage generator) are made of high-quality carbon steel with a long service life.

4. Wide applicability: It is suitable for electrostatic separation of various minerals, such as rutile, rare earth ore, ilmenite, etc.

Automation and safety: Safety designs such as built-in overload protection and high-voltage insulation reduce manual intervention and operation risks.

5. Environmental protection: The dry sorting process does not require water, which reduces environmental impact and reduces operating costs.

6. Low noise: Quiet operation design improves the working environment.

models & specifications

Model | BXJ-2A4-30 | BXJ-2A5-60 |

Capacity | 1-2T/H | 1-3T/H |

Feeding size | 0-3mm | 0-3mm |

Feeding speed | 10-15cm/s | 10-15cm/s |

Arc-Plate size | 1600 | 1600 |

Power | 125W | 125W |

Operation voltage | 0-60KV | 0-60KV |

High voltage current | 0-10MA | 0-10MA |

Machine weight | 1688KG | 2100KG |

Overall size | 2.1*1.6*2.3m | 2.1*1.6*2.5m |

* Note: Technical parameters may vary slightly depending on material characteristics and operational conditions.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.