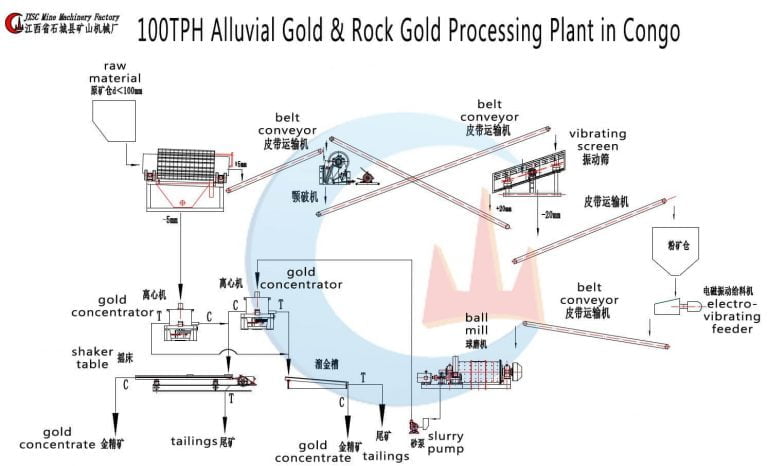

100TPH Alluvial Gold & Rock Gold Processing Plant in Congo

We guarantee the high quality machine in the mineral processing industry, established in 38 years of experience

minerals

mix of alluvial gold and rock gold, contains mud (not very sticky), grade 2 g/t

capacity

100TPH (rock gold 20-30%) in Congo

feed size

0-100mm, gold size 0-2mm

Customer's request

recover gold ore as much as possible, improve gold grade

process flow

1. Alluvial gold process section:

Washing & Screening: trommel screen

The trommel screen cleans the gold ore with a small amount of mud, and screens out two kinds of ores with different particle sizes.

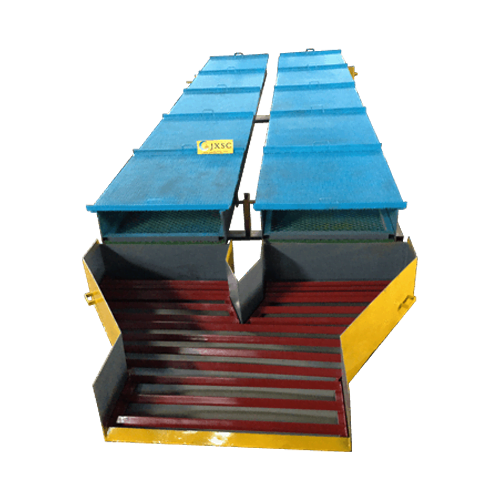

Gravity separation: -5mm material goes to the centrifugal concentrator to catch fine gold particles, sluice box to process the tailing of centrifugal, in order to catch more gold. Shaking table to recover gold concentrate from gold centrifugal concentrator and sluice box.

2. Rock gold process section:

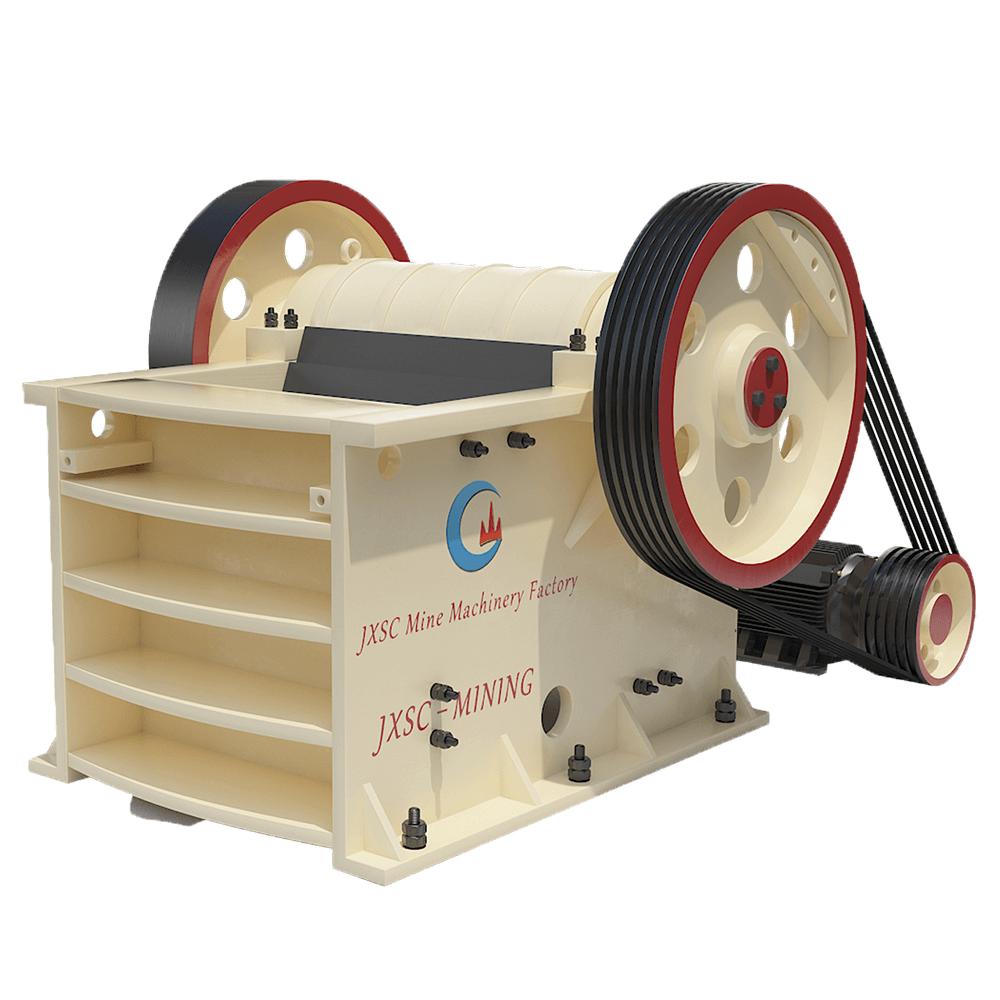

Crushing & Grinding: jaw crusher, vibrating screen, ball mill

The +5mm rock gold stone is transported to the jaw crusher by a belt conveyor for crushing, and then transported to the vibrating screen for screening. +20mm material is conveyed to jaw crusher by belt conveyor for secondary crushing. -20mm material is conveyed to the powder silo by belt conveyor, and then conveyed by belt conveyor to ball mill for pulverization.

Gravity separation: gold centrifugal concentrator, shaking table, sluice box

After ball mill grinding, materials discharge will to centrifugal to recovery gold, concentrate of gold centrifugal will to shaking table for final recovery. Tailing from gold centrifugal will to sluice box to catch more gold.

Gold Processing Plant Solutions & Flow Design

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.