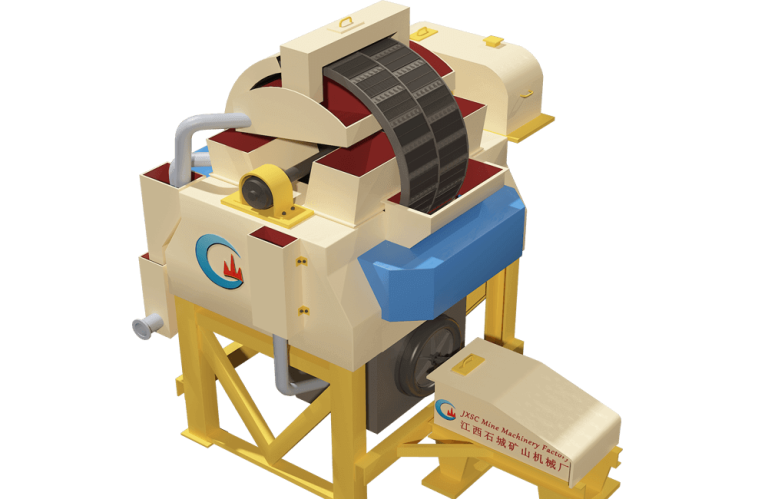

Slurry Magnetic Separator

Capacity: 10-100m³/h

Application: slurry magnetic separator is widely used for separation of weak magnetic substances or iron impurities in slurry and glaze in ceramic, mining, chemical, electronics and other industries; such as iron removal and purification of non-metallic minerals such as feldspar, quartz sand, kaolin, nepheline, fluorite, sillimanite, spodumene, ceramic slurry, etc.

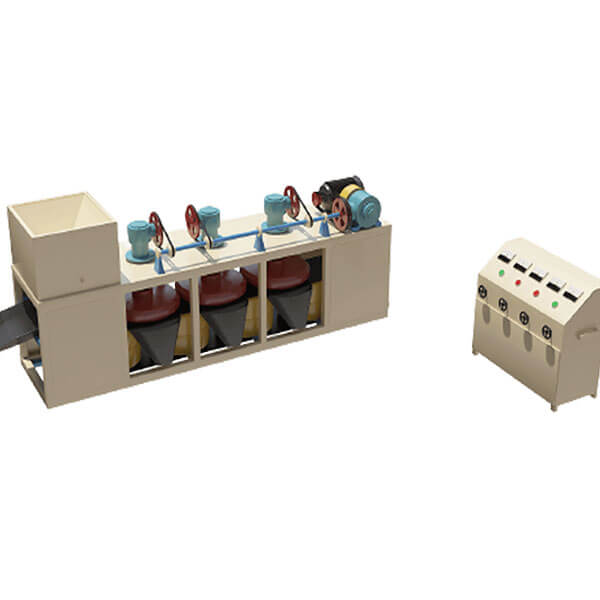

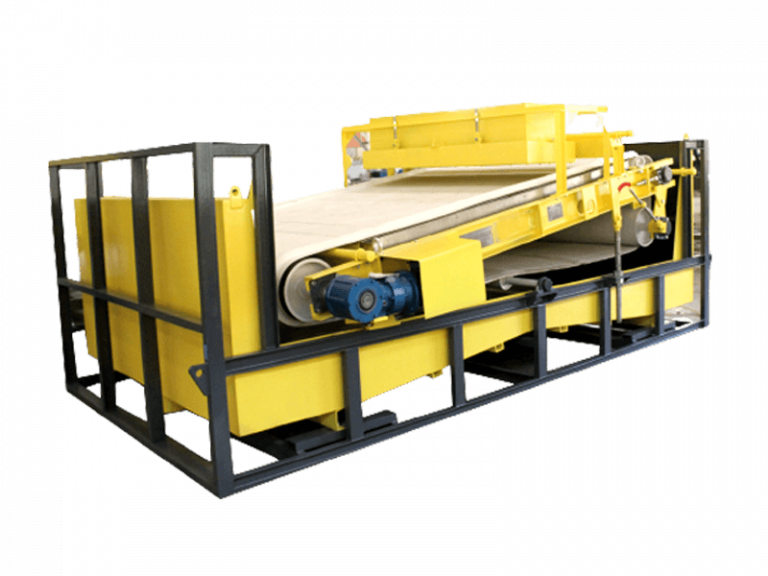

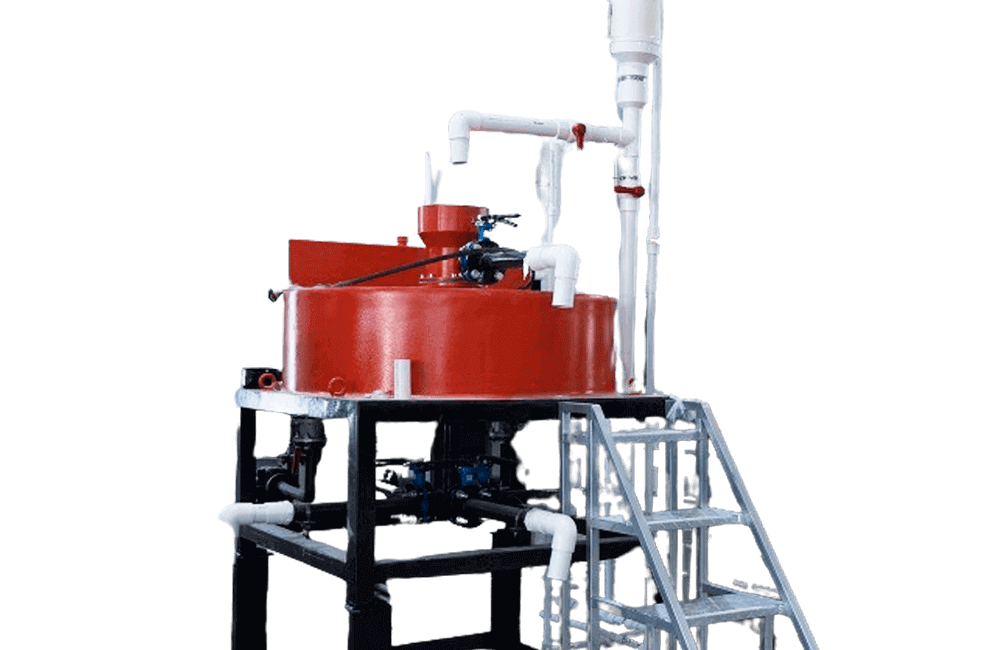

Products display

introduction Of Slurry Magnetic Separator

The slurry magnetic separator is a wet high-intensity magnetic separation equipment. It has a strong adsorption effect on low-content weakly magnetic and fine impurities, and the iron removal effect is very impressive. It automatically absorbs and removes iron and has a strong collection capacity. JXSC slurry magnetic separator can automatically and continuously purify or concentrate weakly magnetic materials.

Through the synergistic effect of high-gradient magnetic fields and fluid dynamics, this device achieves deep separation of fine, weakly magnetic impurities in slurries.

This slurry magnetic separator is widely used in non-metallic mineral purification, metal ore separation, and industrial slurry iron removal. Such as quartz sand, kaolin, and ceramic clay. It is particularly suitable for removing impurities such as iron and titanium from kaolin beneficiation.

- Purification: Reduces impurities such as iron and titanium in non-metallic mineral slurries, improving product purity (e.g., quartz sand purity reaches 99.99%).

- Iron removal: Removes magnetic contaminants from industrial slurries, ensuring subsequent process stability.

- Enrichment: Recovers valuable components from low-grade metal ore slurries.

working principle Of Slurry Magnetic Separator

When slurry (a water mixture containing fine particles) enters the slurry magnetic separator, powerful magnets generate a magnetic field, and materials susceptible to magnetism are pulled toward the magnetic drum or surface. Non-magnetic materials continue to flow unimpeded.

When all the slurry has passed through the ore magnetic separator, close the slurry inlet valve and slurry outlet valve, and discharge the remaining slurry in the magnetic separator through the return valve. Then disconnect the magnet and close the slurry inlet valve, slurry outlet valve and return valve. Open the iron discharge valve to discharge all iron-containing materials adsorbed in the magnetic medium.

why choose JXSC Slurry Magnetic Separator

Features & advantages

1. The JXSC slurry magnetic separator has a high magnetic field, uniform magnetic field distribution, high gradient, and high efficiency in iron separation;

2. It adopts a safe and reliable water-oil dual cooling circulation system to extend the service life of the machine;

3. It has a power-off protection function to ensure long-term operation of the machine with good stability;

4. The slurry magnetic separator uses fully automated control during the iron removal and discharge process, saving time and effort;

5. The final product after magnetic separation is cleaner, less polluting, and easy to clean and operate;

6. The medium is made of special magnetic conductive stainless steel with strong magnetic properties; we support design according to users’ different mineral beneficiation needs.

models & specifications

Model | ZT-YL600-Q | ZT-YL-800-Q | ZT-YL-1000-Q | ZT-YL-1000-T | ZT-YL-1000L-Q | ZT-YL-1200-Q | ZT-YL-1200L-Q |

Input voltage(ACV) | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Power(KW) | 90 | 120 | 150 | 140 | 150 | 178 | 178 |

Magnetic field strength(GS) | 18000 | 18000 | 18000 | 15000 | 18000 | 15000 | 15000 |

Capacity | 10-40m³/h | 15-50m³/h | 20-75m³/h | 20-75m³/h | 20-75m³/h | 25-100m³/h | 25-100m³/h |

Kaolin feed concentration | 10-20% | 10-20% | 10-20% | 10-20% | 10-20% | 10-20% | 10-20% |

Potassium, albite ore concentration | 20-30% | 20-30% | 20-30% | 20-30% | 20-30% | 20-30% | 20-30% |

Weight(T) | 15 | 23 | 32 | 28 | 43 | 45 | 53 |

Output voltage(DCV) | 0-530 | 0-530 | 0-530 | 0-530 | 0-530 | 0-530 | 0-530 |

Output current(DCA) | 0-160 | 0-210 | 0-285 | 0-285 | 0-285 | 0-330 | 0-330 |

Cooling method | Oil and water double cooling | Oil and water double cooling | Oil and water double cooling | Oil and water double cooling | Oil and water double cooling | Oil and water double cooling | Oil and water double cooling |

Coil power(KW) | 80 | 110 | 132 | 120 | 130 | 160 | 160 |

Cavity height(mm) | 700 | 700 | 700 | 800 | 600 | 800 | 700 |

Coil material | Copper | Copper | Copper | Copper | Aluminum | Copper | Aluminum |

Installation size(mm) | 1550*1550*3200 | 1980*1980*3200 | 2300*2300*3200 | 2130*2130*3300 | 2600*2600*3800 | 2600*2600*3300 | 2800*2800*3800 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.