120TPD Lithium Ore Processing Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 38 years of experience

Project Info

Materials: Spodumene ore, raw material grade 2%

Capacity: 120TPD

Feed size: 200mm

Location: Nigeria

Process

Feeding- Crushing & Screening – Grinding & classifying – Flotation – Concentration – Filtration

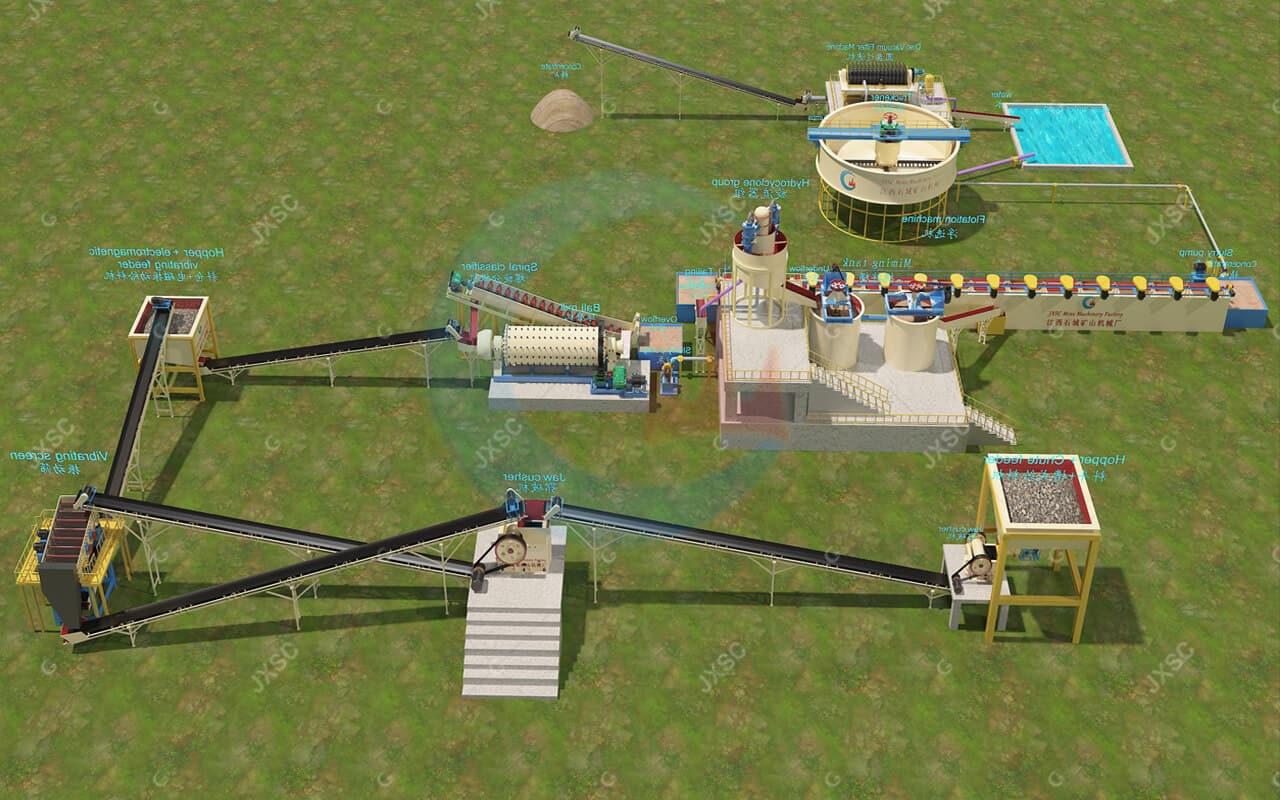

process flow

Based on customer needs, JXSC designed a complete 120TPD lithium processing plant flow, machines and all accessories for Nigerian customers. We mainly provide a complete set of “turnkey solutions“: including preliminary consultation on mining projects, designing and drawing flow charts; going to the site to inspect the ore conditions before starting work; complete sets of processing equipment; and dispatching engineers to the site to guide, install, debug and train workers.

The detailed process is as follows:

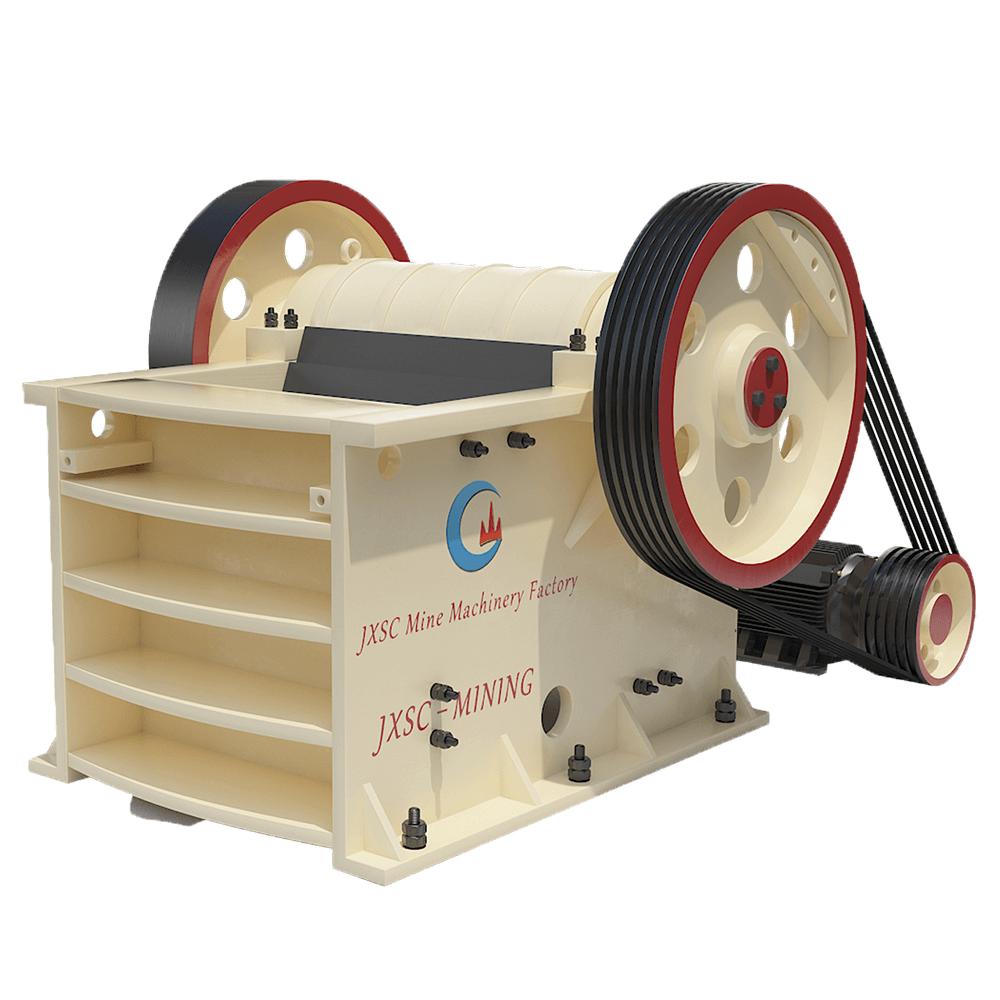

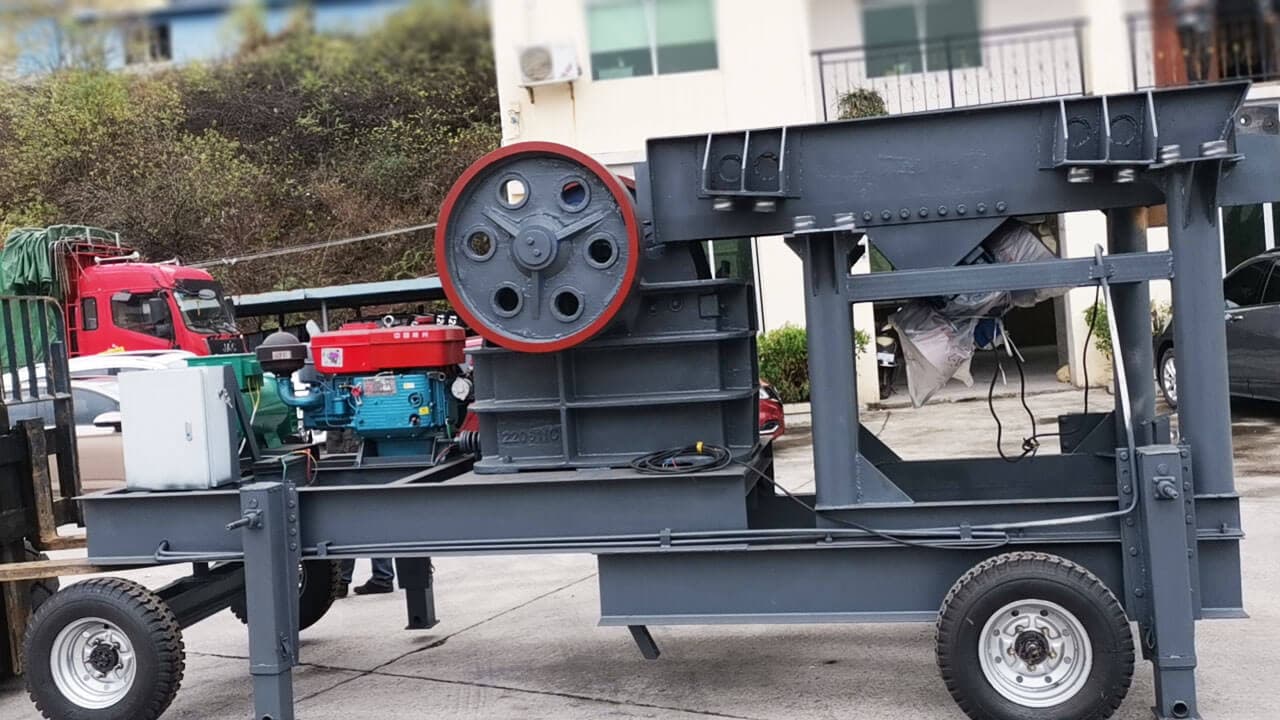

1. Crushing, screening: jaw crusher, vibrating screen

The loader feeds the raw ore into the hopper, and the ore is evenly sent to the jaw crusher through the chute feeder, and then to the fine jaw crusher for fine crushing. The materials are sent to the vibrating screen by the belt conveyor and screened into sizes of 20mm and above. +20mm size will return to the fine jaw crusher for crushing again; materials smaller than 20mm size will enter the next stage.

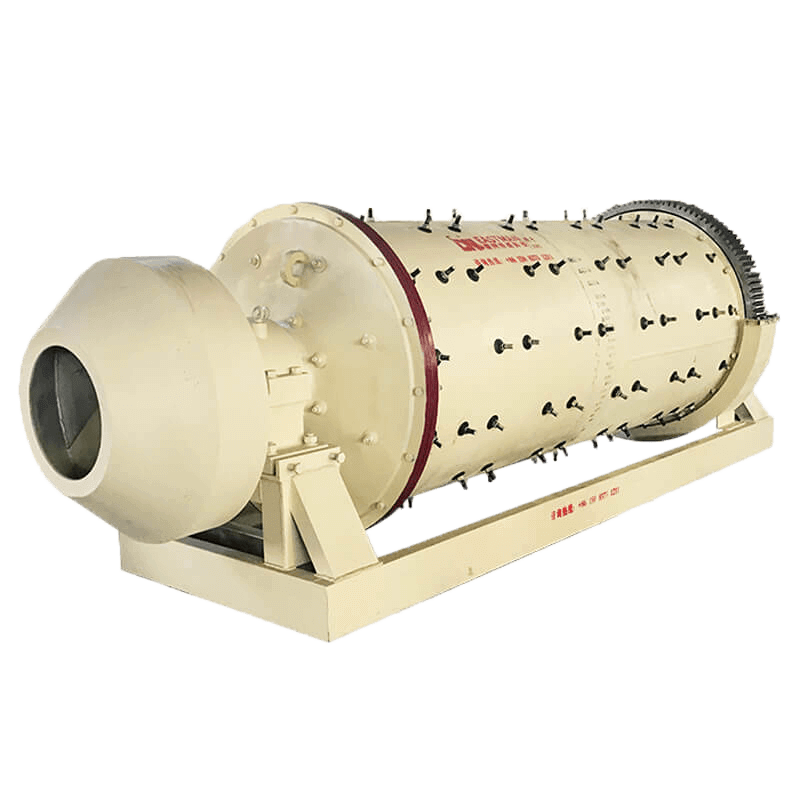

2. Grinding & classifying: ball mill, spiral classifier

After screening, the materials that meet the size are sent to the storage bin by the belt conveyor, and then evenly sent to the ball mill through the electromagnetic vibrating feeder for grinding into powder. The ball mill and the spiral classifier form a closed-circuit ring grinding. The spiral classifier overflows to the next stage, and the underflow returns to the ball mill to grind the materials to meet the size again. The classified materials enter the hydrocyclone group and are classified again to obtain finer materials.

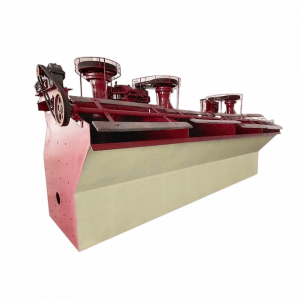

3. Concentration & filtration: mixing tank, flotation machine, thickener, vacuum disc filter

Subsequently, the slurry enters the mixing barrel to fully mix the drugs and slurry, providing qualified grade materials for the flotation section. The slurry is then fed into a flotation machine to process spodumene. The concentrate enters the thickener, and the overflow of the thickener enters the sedimentation tank. The precipitated water can be recycled. The underflow from the thickener enters a disk vacuum filter, which filters it to obtain an almost dry spodumene concentrate.

The concentrate recovery rate of the entire plant is high. We will develop lithium processing solutions, EPC services, processes and equipment according to your mine conditions. Inquire now to get a quote!

Process Site

Main Equipment

Item No. | Product Name | Model No. | Quantity (Set) |

1 | Chute feeder | 600*500 | 1 |

2 | Primary jaw crusher | PE-250*400 | 1 |

3 | Belt conveyor | 650*15m | 5 |

4 | Fine jaw crusher | PEX150*750 | 1 |

5 | Vibrating screen | 1530 | 1 |

6 | Belt conveyor | 650*10m |

|

7 | Electromagnetic vibration feeder | GZ1 | 1 |

8 | Ball mill | MQZ1530 | 1 |

9 | Electronic weight machine | 650 | 4 |

10 | Spiral classifier | FG-10 | 1 |

11 | Slurry pump | 3/2 inch | 4 |

12 | Mixing tank | 1m*1m | 2 |

13 | Flotation machine | SF-1.2 | 17 |

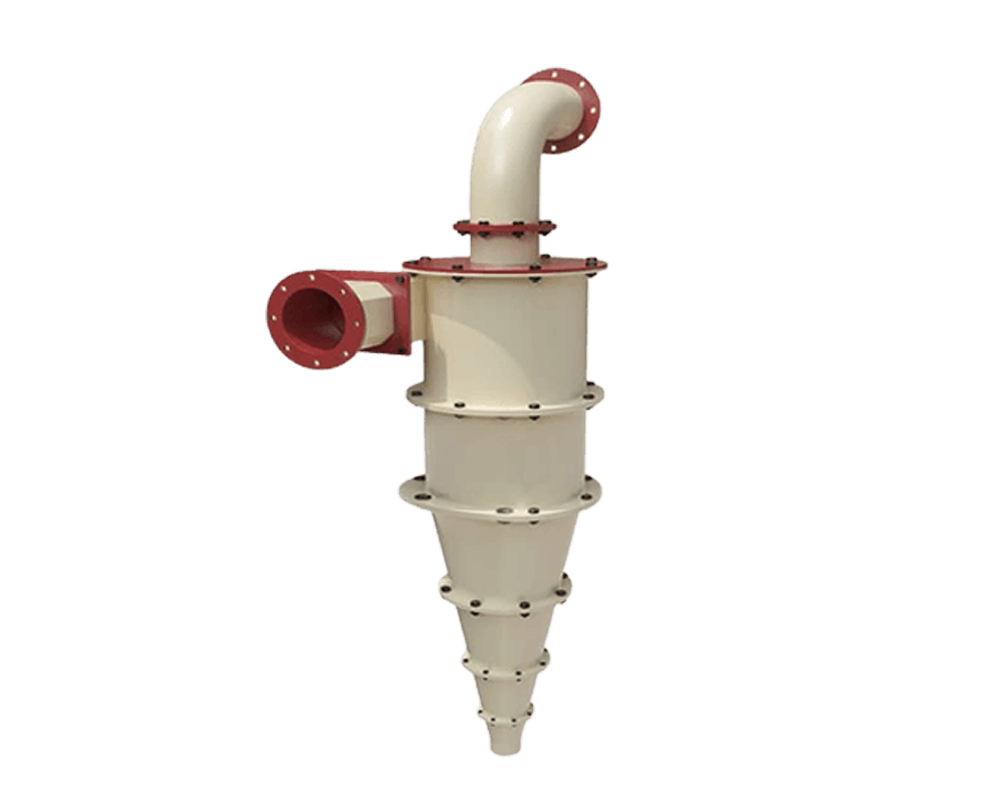

14 | Hydrocyclone | FX100 | 1 |

15 | Water pump for used at water | IS | 2 |

16 | Hihg pressure pump |

| 2 |

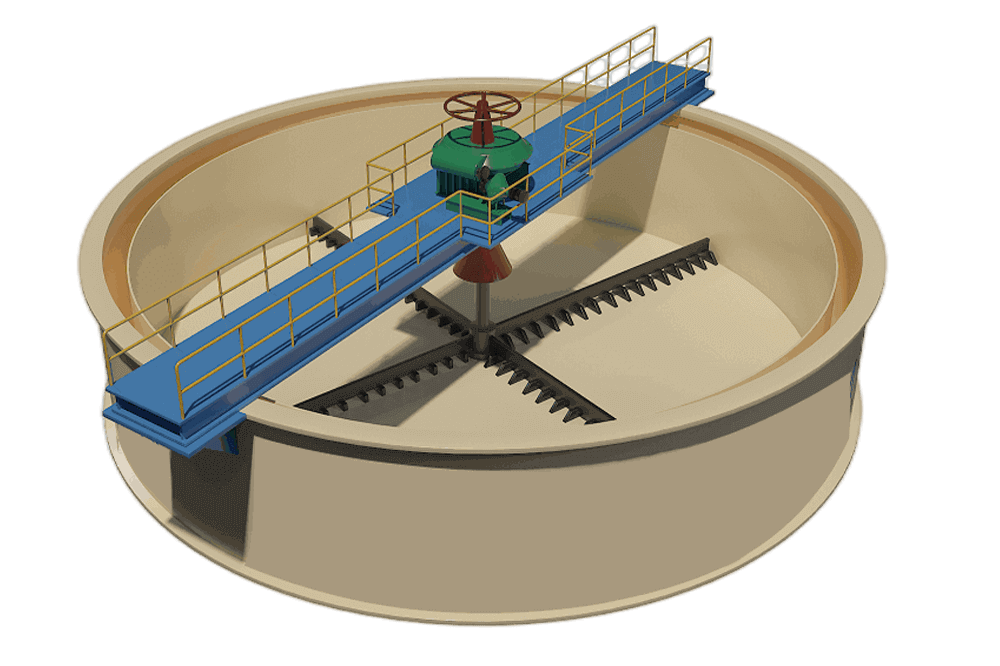

17 | Thickener | NT-9 | 1 |

18 | Disc vacuum filter machine | PGT6-2 | 1 |

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.