Trommel screen

Capacity: 1-200TPH

Feeding size: ≤80-100mm

Application: The trommel screen is used for sand and gravel aggregate and ore classifying, screening, washing, processing; such as gold, copper, silica sand, manganese ore, chrome, iron ore, quartz sand, barite, beach sand, chromium, tantalum-niobium-tin, zircon sand and other ore with low mud content.

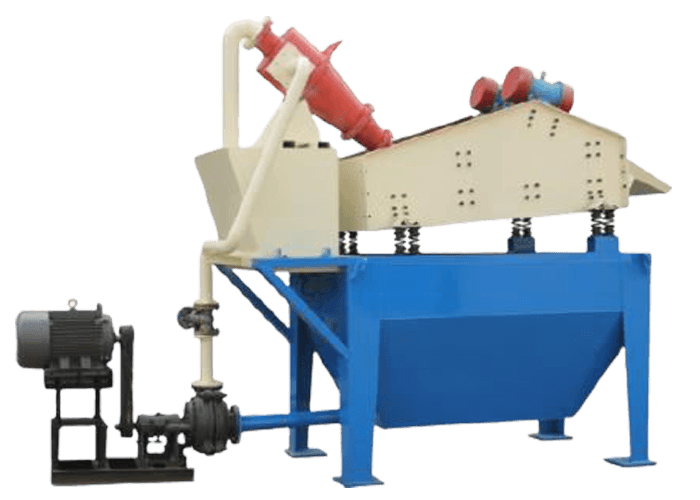

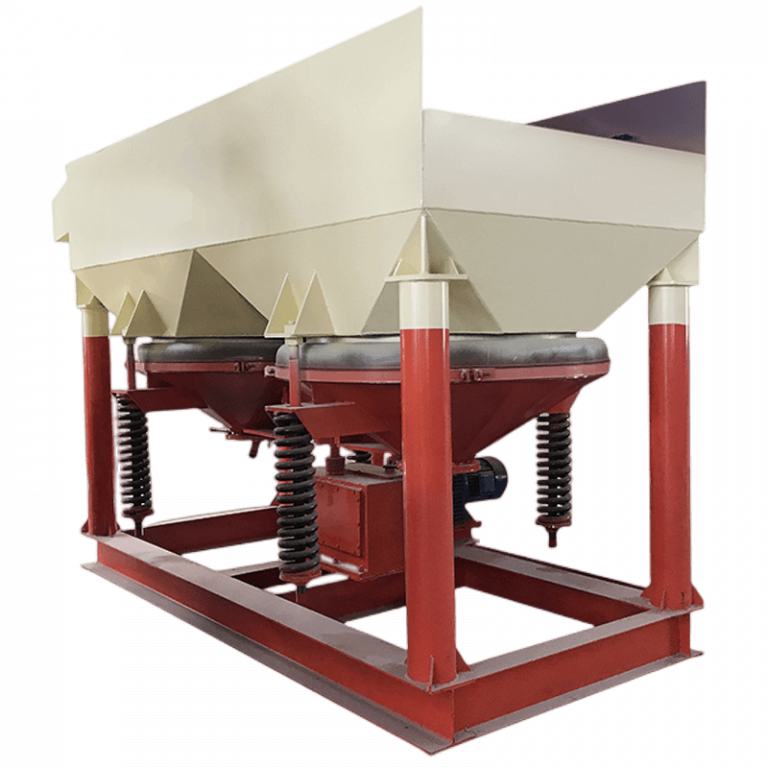

Products display

Introduction of trommel screen

The trommel screen (drum screen) is special equipment that integrates screening and light cleaning functions. It is mainly used for washing mineral raw materials (such as quartz sand, feldspar, limestone, iron ore, etc.) with a mud content of less than 5%. The core function is to efficiently classify, remove impurities and separate materials, and divide the materials into different grades according to the particle size to meet the requirements of material particle size for subsequent processing, transportation, or use. It is especially suitable for washing & screening materials with low viscosity or less impurities. Such as ore (such as iron ore, copper ore, etc.); coal; building materials (such as sand, gravel, etc.); etc.

Trommel screen widely used in some washing & screening operations, including sand, gravel & aggregate plants and the screening of mill discharge streams. JXSC supports customized fixed and mobile/portable trommel screen. They are also used for mineral ore washing and scrubbing processes, such as bauxite, alluvial gold, diamond, chrome, tantalum-niobium tin, iron, kaolin, manganese, etc. Usually combined with wheels and a gold sluice box to form a one-stop mobile gold wash plant.

Its design can not only meet the needs of continuous production, but also ensure high screening efficiency, and is suitable for various mineral cleaning. The drum screen can be used in combination with other equipment, such as crushers, gravity separation, conveyor, etc. It is widely used in the pretreatment stage of mineral processing plant, providing qualified raw materials with a cleanliness level of more than 95% for subsequent flotation, magnetic separation, or deep processing.

This drum screen is not suitable for minerals with a mud content of more than 8% or with strong viscosity; in this case, you need to choose a log washer, trommel scrubber or other ore washing equipment.

principle & structure of trommel screen

working principle

Trommels are installed on a small angle to the horizontal or use a series of internal baffles to transport material along with the cylinder.

When the feeding material enters the roller trommel, due to the tilt and rotation of the trommel, the material on the screen surface is turned and rolled, so that the qualified material (under-screen product) is discharged through the outlet at the bottom of the rear end of the roller, and the unqualified material (upper-screen product) is discharged through the discharge port at the rear of the trommel.

Structural characteristics

- Drum: The inner wall is equipped with a high-manganese steel wear-resistant lining for impact and abrasion resistance.

- Screen system: Woven mesh, perforated mesh, or slit screen plates are available, with adjustable apertures.

- Adjustable inclination: Hydraulically adjustable from 0-5° to accommodate varying material flow characteristics.

- Driving device: The motor drives the drum to rotate through the reducer, and the speed is adjustable.

- Cleansing device: Some models are equipped with a vibrator or brush roller to prevent clogging of the screen apertures.

- Feed and discharge: The feed end is equipped with a deflector, and the discharge end has multiple outlets graded according to the screen aperture.

why choose JXSC trommel screen

features & Advantages

1. Efficient cleaning: The “spray + flip” composite cleaning mode is adopted to remove more than 90% of the tiny clay particles on the surface of the mineral. The sieve holes are not easy to clog and the screening effect is stable.

2. Low loss: Due to the low rotation speed of the drum, the mineral particle breakage rate is less than 1%, which is especially suitable for brittle minerals (such as fluorite and barite).

3. Controllable classification accuracy: According to different production processes and material characteristics, different types of screens can be configured to meet the personalized needs of users.

4. Durable: The screen is made of polyurethane or stainless steel, which can work for a long time in harsh environments and has a long service life.

5. Water-saving and energy-saving design: Compared with other washing and screening equipment, the drum screen has lower energy consumption. The recycling rate of washing water is more than 80%.

6. Wide adaptability: It can adapt to minerals of different density and hardness by adjusting the drum inclination, rotation speed, and spray pressure.

7. Intelligent integration: Optional PLC control system, real-time monitoring of screen blockage, cleaning water pressure and material flow, automatic start and stop backwashing device, and reduce manual intervention costs.

8. Environmental protection: During the operation of the equipment, the noise generated by the material and the rotating screen is completely isolated by the sealed dust cover, eliminating the flying dust during the screening process and providing a good operating environment.

9. Flexible configuration: The JXSC drum screen can be equipped with wheels to form a portable or mobile trommel screen, which can be flexibly and quickly deployed to any site.

models & specifications

Model | Screen Size(mm) | Feeding Size(mm) | Drum Dia (mm) | Drum length (mm) | Process Capacity(t/h) | Motor Power(kw) |

GT0513 | ≤20 | ≤80 | 500 | 1300 | 1-5 | 3 |

GT0813 | ≤20 | ≤80 | 800 | 1300 | 5-10 | 4 |

GT1015 | ≤20 | ≤80 | 1000 | 1500 | 10-15 | 5 |

GT1020 | ≤25 | ≤80 | 1000 | 2000 | 15-20 | 5.5 |

GT1225 | ≤25 | ≤100 | 1200 | 2500 | 20-50 | 7.5 |

GT1530 | ≤25 | ≤100 | 1500 | 3000 | 40-70 | 11 |

GT1545 | ≤25 | ≤100 | 1500 | 4500 | 70-100 | 15 |

GT1848 | ≤50 | ≤100 | 1800 | 4800 | 100-150 | 22 |

GT2055 | ≤50 | ≤100 | 2000 | 5500 | 150-200 | 30 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.