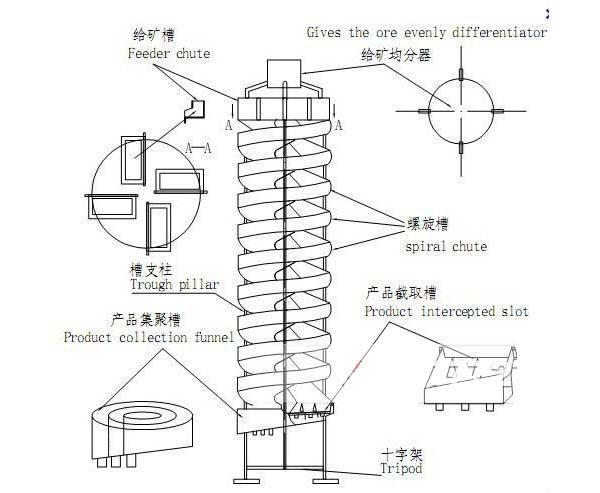

Spiral Separator

Capacity: 0.15-10t/h

Feeding size: 0.02-2mm

Application: Spiral separator (spiral chute) is widely used for processing fine-grained gold, iron, ilmenite, chromite, pyrite, zircon, rutile, monazite, phosphorite, tungsten ore, tin ore, tantalum-niobium ore, minerals with different specific gravity, other non-ferrous metals, rare metals and non-metallic minerals separation; and also be used for placer mining on seashores, riversides, beaches, and streams.

Products display

Introduction of spiral separator

Spiral separator, or spiral chute especially sand mining in the seashore, riverside, sand beaches, and streams. Spiral chute is a device that combines the characteristics of spiral concentrator, spiral chute, shaker table, and centrifugal concentrator. It is the best gravity separation equipment for placer ore mining and beneficiation. Highly efficient recovery of fine-grained heavy minerals, a single device can complete roughing-scavenging-concentrate separation with low energy consumption. The spiral chute is used to separate fine-grained all metal and non-metallic minerals with sufficient specific gravity difference. The sorting process is stable and easy to control, the allowable range of feed concentration is wide, high enrichment and recovery rate.

Core function of spiral separator

- Metal ore sorting: gold, copper, tungsten, tantalum-niobium, iron ore, ilmenite, tungsten ore, tin ore, rutile, etc.

- Rare earth and rare metals beneficiation: purification of zircon and monazite in beach sand.

- Non-metal ore processing: iron removal from quartz sand, separation of feldspar and mica.

- Environmental recycling: tailings re-selection, metal recovery from electronic waste.

working principle & structure of Spiral separator

working principle

The spiral chute mainly uses the inertial centrifugal force generated by the minerals of different densities in the spiral rotation to achieve the separation of light and heavy minerals. Because of its simple equipment structure, low power consumption, and large processing capacity, it is widely used in the gravity separation process. Chute beneficiation belongs to the bevel flow separation process. The slurry is given to a certainly inclined chute. Under the impetus of water flow, the ore particles are loose and layered. The upper layer of light minerals is quickly discharged from the tank, and the lower layer of heavy minerals is retained in the tank or discharged from the lower part at a low speed. After that, concentrate and tailings are obtained.

Structural features

- Spiral Trough: The main body consists of multiple spiral grooves lined with wear-resistant materials (such as fiberglass, rubber, or polyurethane).

- Feeder: Located at the top, it evenly distributes the slurry into the spiral trough.

- Flushing Water System: Adjustable water flow controls the width of the separation belt.

- Cutter: A circular discharge chute with three outlets: concentrate, middlings, and tailings.

- Support: A welded steel structure with adjustable inclination to accommodate different ore types.

why choose JXSC spiral separator

Features & advantages of spiral separator (spiral chute)

1. Wide applications: Suitable for sorting tungsten, tin, gold, platinum, iron, and some rare metal ores, especially low-grade placer ores.

2. Efficient concentration: Excellent sorting accuracy, stable performance, clear separation zones, and high recovery rates.

Superior Economy: No power consumption, relying solely on gravity and centrifugal force, resulting in low energy consumption and operating costs.

3. Adaptability: Suitable for processing a variety of minerals with significantly different densities, with flexible equipment adjustments (inclination, water volume, etc.).

4. Easy maintenance: Moisture-resistant, rust-proof, and corrosion-resistant, with no moving parts subject to significant wear, ensuring a long service life.

5. Continuous operation: Automatic discharge, high stability, and minimal manual intervention.

6. Flexible configuration: Supports multiple spirals connected in series (roughing-scavenging) or in parallel (to increase throughput), offering modular and versatile configurations.

7. Small footprint: Vertical layout makes it suitable for concentrators with limited space.

8. Environmentally friendly: No chemicals are required, and tailings water can be directly recycled, making it suitable for mining areas with strict environmental requirements.

models & specifications

Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

Outside Dia (mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 |

Pitch (mm) | 1200 | 540, 720 | 900, 720, 540 | 675, 540, 405 | 450, 360, 270 | 240, 180 |

Pitch Dia Ratio | 0.6 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.75, 0.6, 0.45 | 0.6, 0.45 |

Lateral Slope | 9° | 9° | 9° | 9° | 9° | 9° |

Maximum Starts Per Column | 2 | 4-2 | 4-2 | 4-2 | 2 | 2 |

Feeding Size (mm) | 2-0.04 | 0.3-0.02 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

Feeding Density(%) | 30-55 | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

Capacity (T/H) | 7-10 | 6-8 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

Length (mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 |

Size Width (mm) | 2120 | 1560 | 1360 | 1060 | 700 | 460 |

Height (mm) | 5600 | 5230 | 5230 | 4000 | 2600 | 1500 |

Weight (Kg) | 1200 | 800 | 600 | 400 | 150 | 50 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.