vibrating feeder

Capacity: 20-1200TPH

Feeding size: <1000mm

Application: Vibrating feeders can be used to convey bulk, granular, and powdery materials; for example: gold, iron ore, copper ore, limestone, granite, pebbles, coal, limestone, marble, coke, cement, sticky, wet materials and other sand and gravel aggregates or ores.

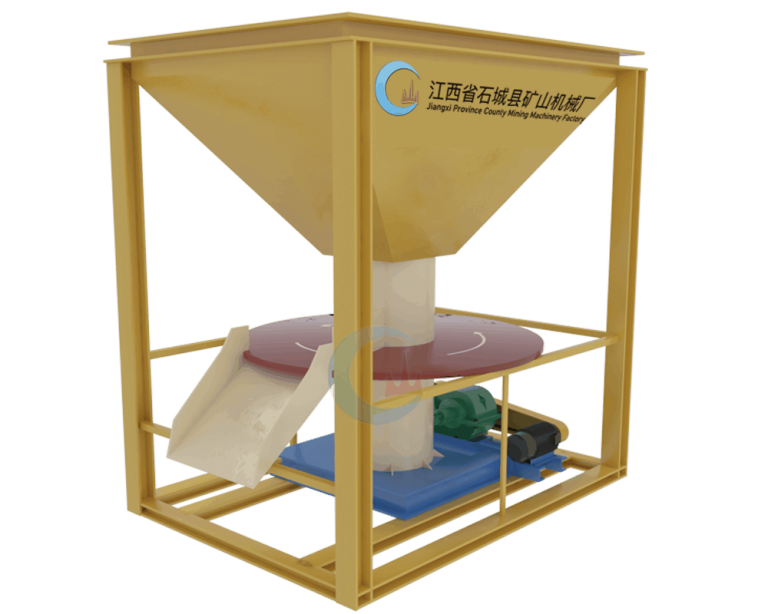

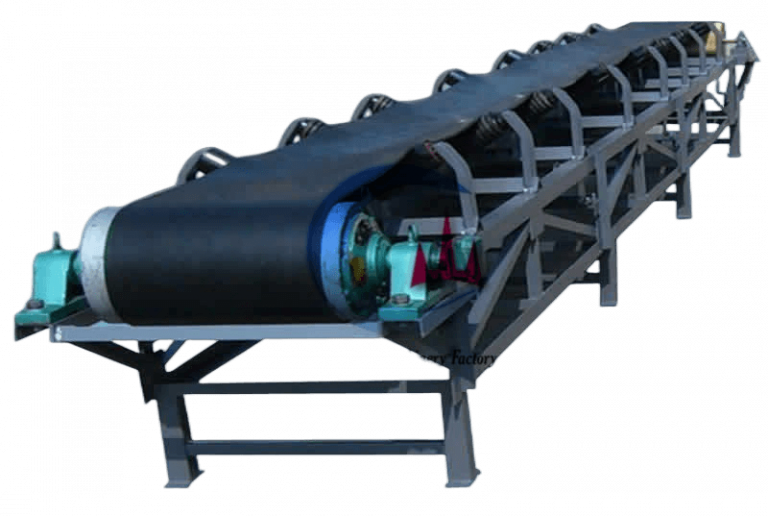

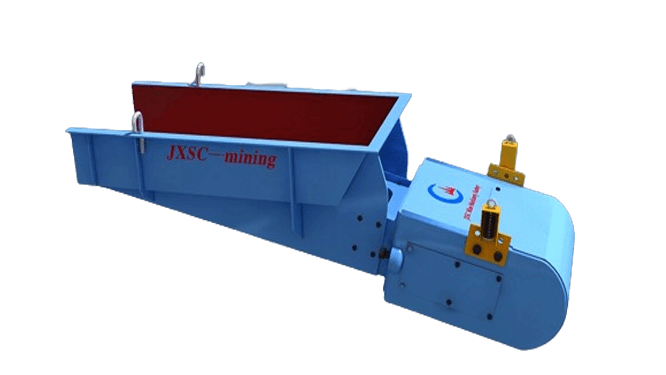

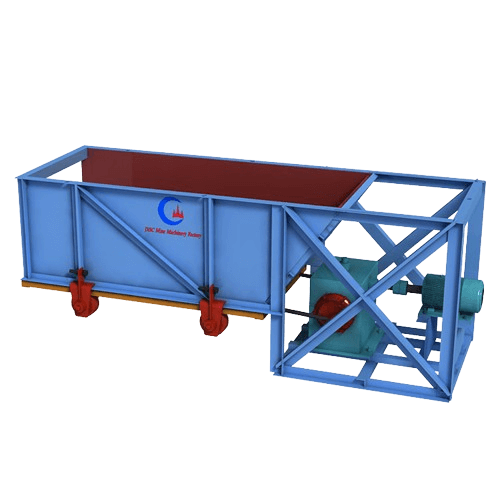

Products display

Introduction of vibrating feeder

A vibrating feeder is an efficient, precise, and controllable material feeding & conveying equipment. It utilizes chute vibration to evenly and continuously convey bulk, granular, or powdered materials from hoppers, silos, and bins to downstream equipment such as crushers, screens, and conveyors. It primarily uses a vibrating motor or electromagnetic drive to generate directional vibration, forcing the material to move in a specific direction. The core functions of this vibrating feeder are quantitative feeding and flow control. It is widely used in the feeding stage of industries such as mining, metallurgy, building materials, chemicals, power generation, grain processing, and aggregate production.

Frequency conversion allows for variable feed rate and speed to meet the material requirements of different process steps. Some models can also incorporate screens to separate fine materials during the feeding process, achieving an integrated “feeding and screening” system and streamlining production processes.

JXSC vibrating feeder has the advantages of high feeding accuracy, easy adjustment, energy saving, and environmental protection. It is the key equipment connecting the storage and processing links in industrial production lines.

principle and structure of vibrating feeder

Working principle

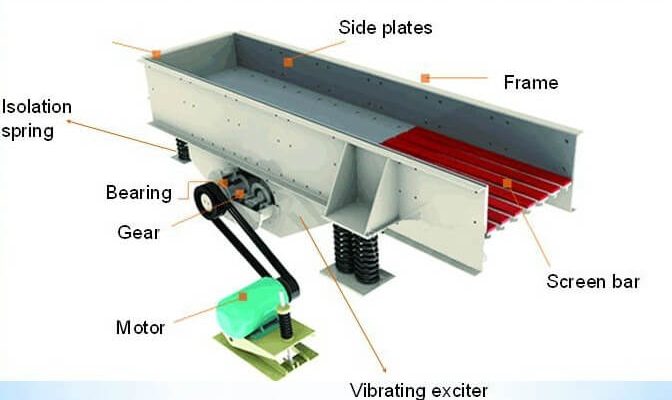

It is mainly composed of vibration frame, spring, vibrator, motor vibration frame and motor. When the two vibrating motors rotate synchronously in opposite directions, the components of the exciting force generated by the eccentric block cancel each other out in the X direction. The vibrating motor only needs to adjust the eccentric blocks on the outer sides of both ends to make the angle formed by the eccentric blocks on the inner side, then the exciting force can be adjusted steplessly, and the flow rate of the feeder can be changed and controlled. Correspondingly, the material is continuously thrown up and jumps forward, so that the material moves forward evenly and continuously to achieve the purpose of feeding.

Structural characteristics

- Excitation device: Vibration motor (with eccentric weight for adjusting the excitation force) or electromagnetic exciter.

- Feed trough: Available in carbon steel, stainless steel, or wear-resistant lining.

- Elastic system: Includes support springs (helical, rubber, or leaf springs) to reduce vibration transmission; excitation springs transmit the excitation force.

- Control system: Adjusts vibration frequency and amplitude for precise feeding.

Why Choose JXSC vibrating feeder

features & advantages

√ High Efficiency and Energy Saving: Utilizes advanced vibration motor or electromagnetic drive technology for low energy consumption. No transmission parts to wear, resulting in low maintenance costs and a long service life.

√ Precise and Controllable: Equipped with a variable frequency control system, the conveying capacity can be infinitely adjusted with fast response.

√ Intelligent Control: Optional PLC/DCS system integration enables remote monitoring.

√ Rugged and Durable: The trough body utilizes high-strength steel plates or wear-resistant linings to withstand heavy impact loads or highly abrasive materials.

√ Environmentally Friendly: Dust-proof and sealed design reduces dust pollution.

√ Versatile: Customizable options such as explosion-proof, corrosion-resistant, and high-temperature resistant meet the needs of specialized industries such as chemical and metallurgical industries.

√ Easy Installation: The modular design allows for direct installation on the silo bottom or seamless integration with equipment.

models & specifications

| Model | Funnel Size(mm×mm) | Input size(mm) | Capacity(t/h) | Motor Power(kw) | Weight(kg) | Dimensions(mm) |

| GZD-800×3000 | 800×3000 | 400 | 80-120 | 2.2 | 3195 | 3110×1800×1600 |

| GZD-960×3800 | 960×3800 | 500 | 120-210 | 2.2×2 | 3375 | 3850×1950×1630 |

| GZD-1100×4200 | 1100×4200 | 580 | 200-430 | 3.7×2 | 4400 | 4400×2050×1660 |

| GZD-1100×4900 | 1100×4900 | 580 | 280-500 | 5.5×2 | 4675 | 5200×2050×1700 |

| GZD-1300×5200 | 1300×5200 | 650 | 450-600 | 7.5×2 | 5400 | 5200×2350×1750 |

| ZSW-950×3800 | 950×3800 | 500 | 96-160 | 11 | 4100 | 3882×2224×2121 |

| ZSW-1100×4200 | 1100×4200 | 580 | 120-240 | 15 | 4745 | 4310×2500×1365 |

| ZSW-1100×4900 | 1100×4900 | 580 | 120-280 | 15 | 5420 | 4957×2500×1365 |

| ZSW-1100×5900 | 1100×5900 | 630 | 160-350 | 22 | 6100 | 6000×2500×2150 |

| ZSW-1300×5900 | 1300×5900 | 630 | 250-400 | 37 | 6300 | 6000×2700×21 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.