15TPH Rock Gold Ore Crushing Process Plant In Guyana

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience.

Project Info

1.Raw ore: rock gold ore

2.Capacity: 15TPH

3. Feed size: <500mm

4. Output: 0-2mm

5. Location: Guyana

Process

Feeding – Crushing – Screening – Grinding and Classification – Gravity separation

process flow

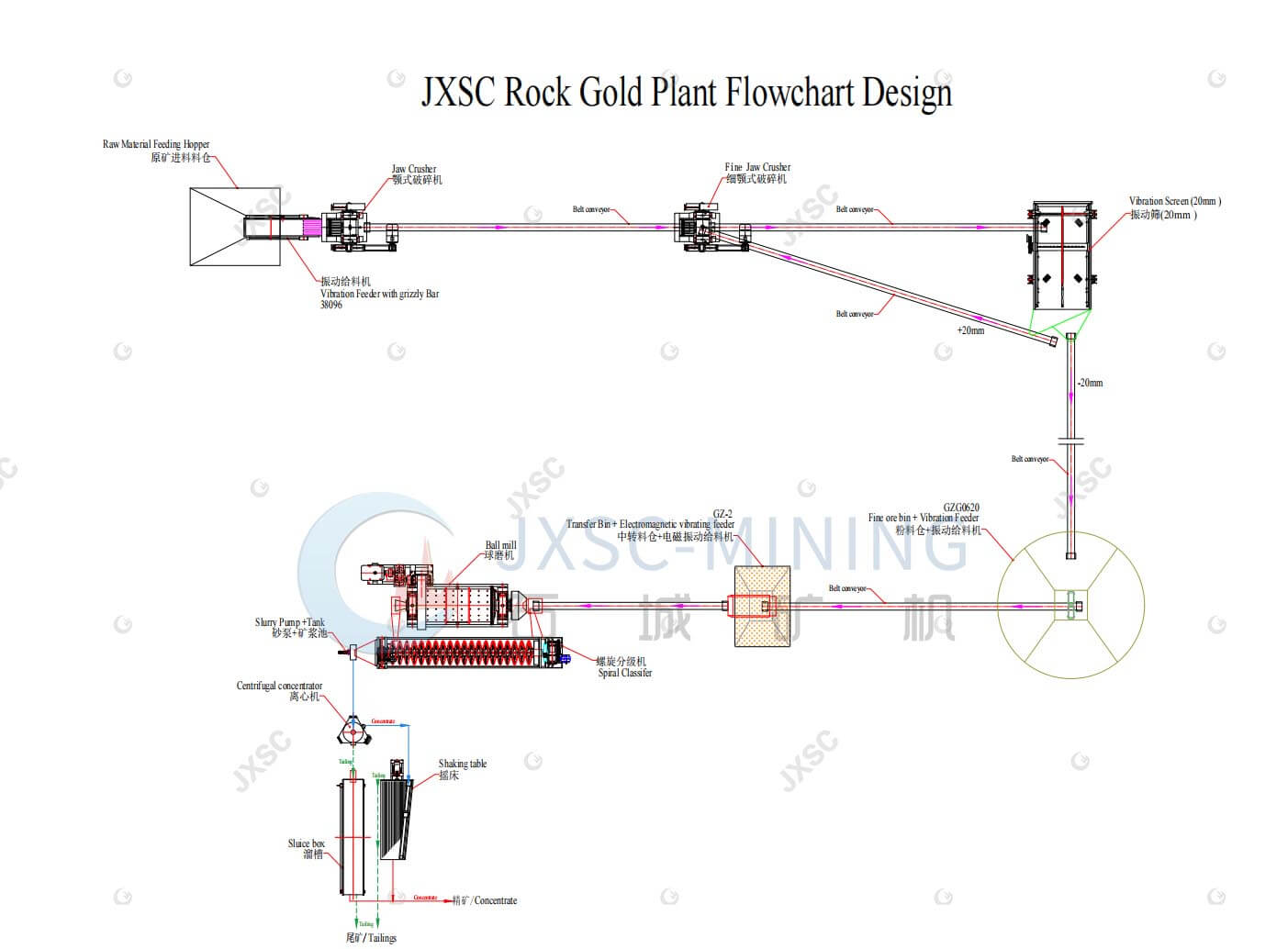

15TPH Rock Gold Ore Crushing Process Plant Flow

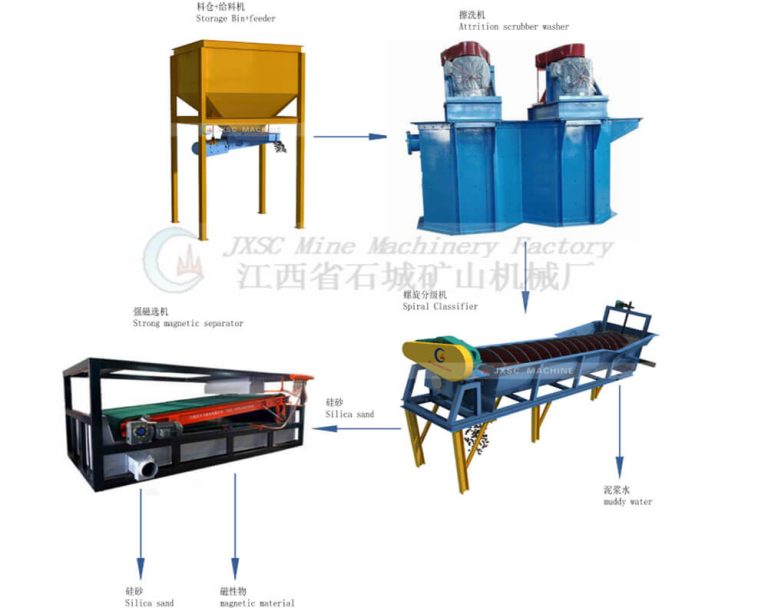

This is a complete set of 15TPH rock gold ore crushing process plant provided by JXSC for Guyana customers, which mainly includes two crushing, screening, grinding and grading, and gravity separation processes. The specific process is as follows:

1. Feeding process

The loader or excavator feeds the gold ore into the raw ore feed bin (customer-made). Then, the material is evenly fed into the primary jaw crusher through the vibrating feeder with a grid below.

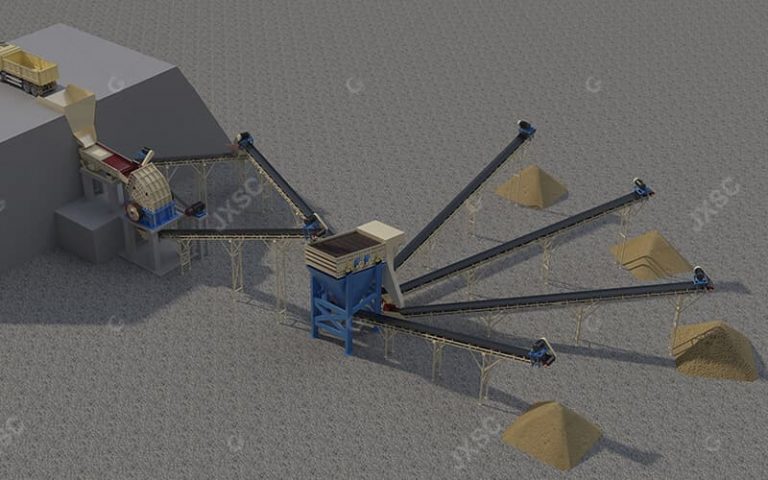

2. Crushing and screening

The primary jaw crusher crushes large stones into medium sizes, and its output is conveyed to the fine jaw crusher through a belt conveyor. Then the medium-sized rocks are crushed into smaller sizes. Among them, the output of the fine jaw crusher is sent to the vibrating screen through a belt conveyor to screen out qualified sizes below 20 mm. Before being sent to the ball mill, the oversized rocks larger than 20 mm are returned to the fine jaw crusher through the belt conveyor for further crushing. Then, the materials smaller than 20mm first enter the powder bin through the belt conveyor and are sent to the transfer bin through the vibrating feeder. All the fine materials that meet the requirements will enter the ball mill through the electromagnetic vibrating feeder + belt conveyor.

3. Grinding and Classification

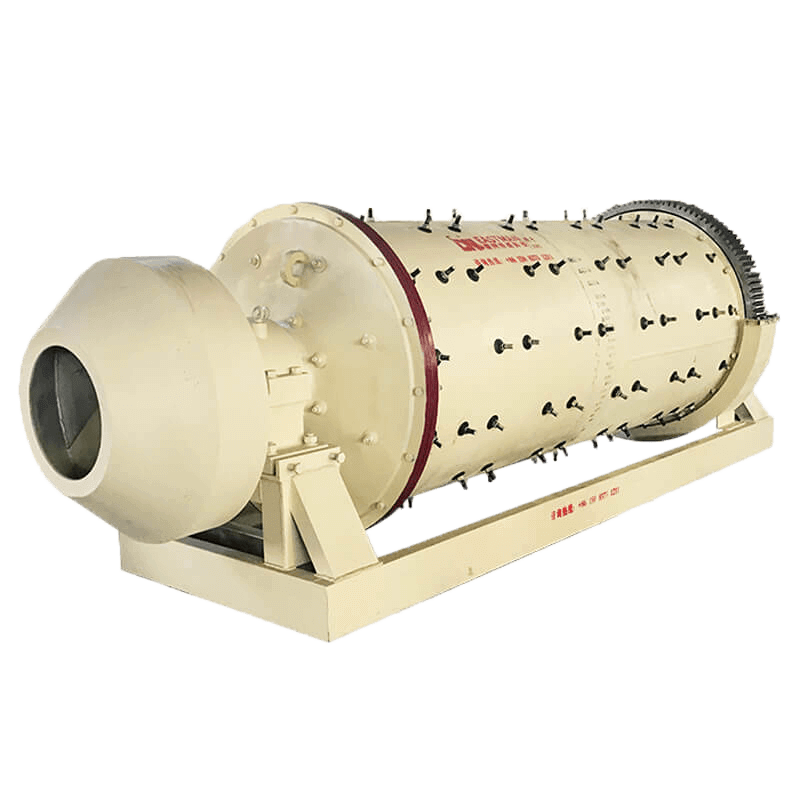

The ball mill grinds fine ore into powder size to release the fine gold in the rock. The discharge of the ball mill then enters the spiral classifier for rough-size separation. The coarse particles will return to the ball mill for re-grinding to ensure the centrifuge feed size is reached.

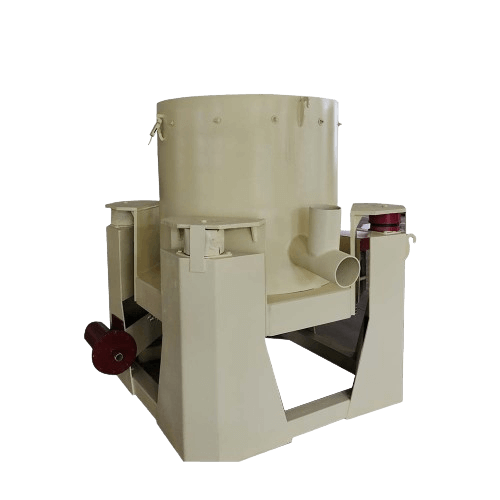

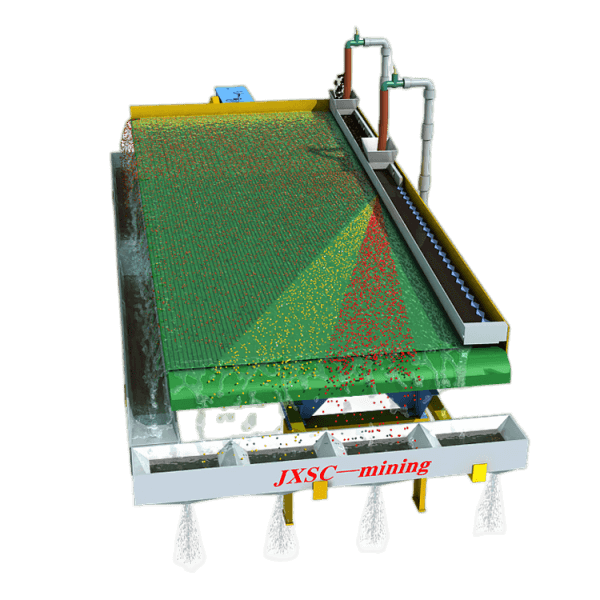

4. Gravity Separation

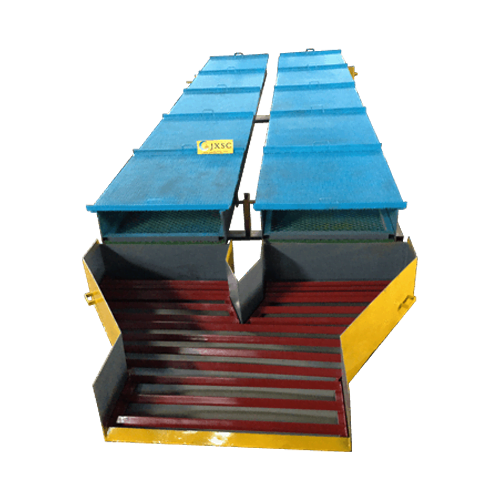

The fine particles will be sent to the centrifugal concentrator through a slurry pump to concentrate the fine gold. The tailings of the centrifuge enter the chute to recover more gold. Finally, all the chute and centrifugal concentrator concentrates will be sent to the shaking table to concentrate the fine gold further.

The rock gold ore crushing plant is very suitable for recovering fine powder gold in rocks. If necessary, a melting furnace can also be added to the tail to melt the gold into gold nuggets or bars. We can produce different capacities according to customer requirements, such as 5TPH, 10TPH, 20 TPH, and 50 TPH. Contact us for more details!

Main Equipment

No. | Equipment name | Model | Quantity |

1 | Raw Material Feeding Hopper | Customer-made | 1 |

2 | Vibration Feder | DN-38096 | 1 |

3 | Primary Jaw Crusher | PE-400×600 | 1 |

4 | Belt Conveyor | B650*15m | 1 |

5 | Fine Jaw Crusher | PEX-250×1000 | 1 |

6 | Belt Conveyor | B650*15m | 1 |

7 | Vibrating Screen | YK1530 | 1 |

8 | Belt Conveyor | B650*14m | 1 |

9 | Belt Conveyor | B650*21.5m | 1 |

10 | Fine ore bin | GZG0620 | 1 |

11 | Vibration Feeder | GZG0620 | 1 |

12 | Belt Conveyor | B650*(4.5+26.5)m | 1 |

13 | Transfer Bin | Customer-made | 1 |

14 | Electromagnetic vibrating feeder | GZ2 | 1 |

15 | Belt Conveyor | B650*10m | 1 |

16 | MQY1845 | 1 | |

17 | FG-1510 | 1 | |

18 | Slurry Pump | 4/3 | 1 |

19 | STLB-80 | 1 | |

20 | Sluice box | 6000×1000 | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.