Quartz Sand VS Silica Sand

Quartz sand, also known as silica sand, can be made into high-purity quartz sand after beneficiation and purification, which is widely used in glass, ceramics, metallurgy, casting and refractory materials industries.

- The main mineral of silica is quartz, and generally contains various impurity minerals such as feldspar, mica, clay and iron.

- The chemical composition of quartz is silicon dioxide (SiO2), and high-purity quartz sand means that the SiO2 content is higher than 99.9%. Quartz sand is a silicate raw material obtained through crushing and purification.

To make high-purity and ultra-high-purity quartz raw materials, it is necessary to remove all impurities except silica. The harmful impurities are composed of minerals containing iron and aluminum. The purification of raw materials is mainly reflected in the effective removal of impurities containing iron and aluminum.

Silica sand

Silica sand includes ordinary silica sand, refined silica sand and high-purity silica sand. The content of silica in ordinary silica sand is between 90% and 99%, and the content of iron oxide is less than 0.02%; the content of silica in refined silica sand is between 99% and 99.5%, and the content of iron oxide is less than 0.015%; high-purity quartz The content of silica in sand is between 99.5% and 99.9%, and the content of iron oxide is less than 0.001%.

Silica sand with higher purity is milky white. When there is a large amount of impurities, silica sand will appear brownish red, light brown and other colors. The melting point of silica sand is about 1750℃, the particle size is between 0.02mm and 3.35mm, and it is insoluble in removing hydrogen and fluorine. Acids other than acids have good chemical stability, electrical insulation, and wear resistance.

The major glass-producing countries, such as the Soviet Union, the United States, Belgium and others, mostly use natural silica sand as raw materials for glass. The quality of natural silica sand in my country is relatively poor. Generally, silica sand crushed by quartz sandstone is used as the raw material for glass.

Quartz sand

Quartz sand is a quartz particle produced by crushing quartz stone. Quartz stone is a non-metallic, hard, wear-resistant, and chemically stable silicate mineral. The color of quartz sand is milky white, or colorless and translucent, with a Mohs hardness of 7.

Quartz sand is an important industrial mineral raw material, non-chemical dangerous goods, widely used in glass, casting, ceramics and fireproof materials, smelting ferrosilicon, metallurgical flux, metallurgy, construction, chemical industry, plastics, rubber, abrasives, filter materials and other industries.

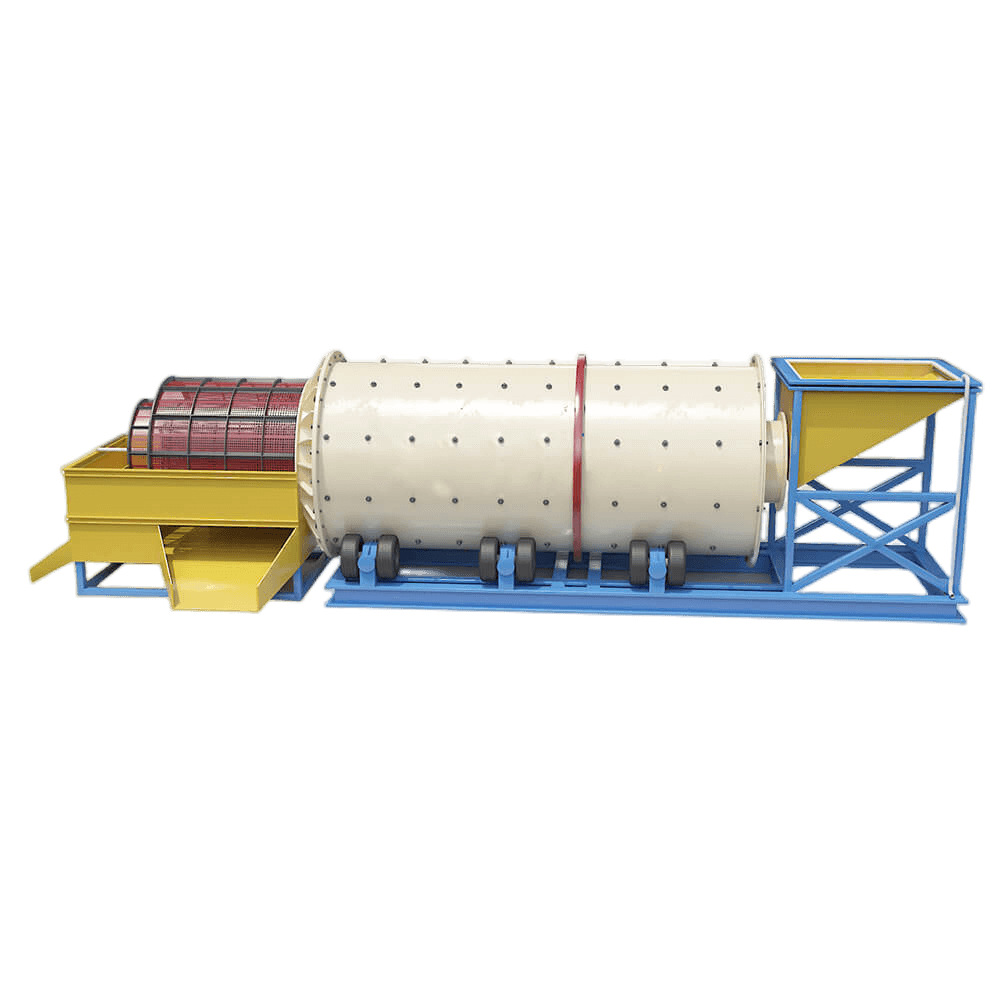

Silica Sand Processing Plant

Mineral processing plant

The grade of raw quartz sand in the industry is getting lower and lower. To meet the needs of the industry, the grade can be improved through the beneficiation process. There are mainly the following silica sand purification methods:

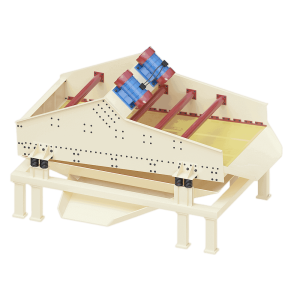

1. Scrubbering

Scrubbing refers to the removal of thin-film iron, adhesive and muddy impurity minerals on the surface of the quartz sand by mechanical force and the abrasive force between the sand grains, and further smashing the unconsolidated mineral aggregates, and then further purifying the quartz sand through classification operations Effect. Today there are mainly rod scrubbing and mechanical scrubbing. The main factors affecting the scrubbing effect are the structural characteristics and configuration of the scrubbing machine; the secondary factors are scrubbing time and scrub concentration (the scrubbing concentration is generally 50%-60%). The main methods include mechanical scrubbing, rod scrubbing, high-efficiency and powerful scrubbing with drugs, and ultrasonic scrubbing.

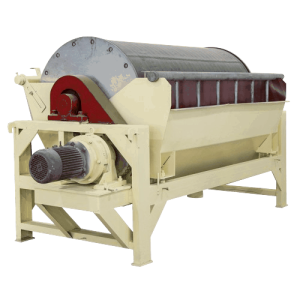

2. Magnetic separation

Magnetic separation is mainly used to remove magnetic minerals in quartz sand. For example, weak magnetic minerals such as hematite, limonite, and biotite can be removed by a strong magnetic machine. In contrast, a weak magnetic separator can remove strong magnetic minerals such as magnetite Remove.

3. Flotation

Flotation removes some impurities that magnetic separation cannot remove, such as feldspar and mica in the quartz sand, to further improve its purity.

4. Acid leaching

Acid leaching utilizes the characteristic that quartz is insoluble in acid (except HF acid), and other impurity minerals can be dissolved in acid, which can realize further purification of quartz.

5. Microbial leaching

It refers to using microorganisms to leach thin film iron or immersion iron on the surface of quartz sand particles. This is a newly developed iron removal technology.

Process flow:

- Stones enter the warehouse

- Rough crushing

- Fine crushing

- Sand making

- Sand washing

- Beneficiation

- Drying

If you need silica sand/ quartz sand processing beneficiation plants, please contact us to customize the equipment and get the factory price!

Silica Sand Processing Plant Videos