In the beneficiation process plant, the purpose of classification operation is to effectively separate coarse and fine particles, which not only avoids the over-grinding of fine-grained minerals, reduces unnecessary energy consumption, but also makes coarse-grained minerals return to the mill as return sand to be effectively pulverized again. The quality of the grading operation will directly affect the production capacity of the grinding equipment, the effect of the finished product, and the technical and economic indicators such as the concentrate grade and recovery rate in the subsequent sorting operation. Among them, the spiral classifier and the hydrocyclone are the most commonly used classificiation equipment, so which one is better?

About equipment introduction

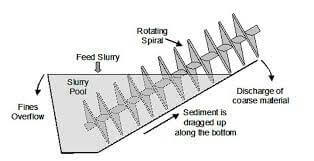

Spiral classifier is suitable for the flow ore sand in the beneficiation plant, the particle size classification of the ore pulp in the metal beneficiation process, and the desliming and dewatering operations in the ore washing operation. It is especially suitable for washing, grading, impurity removal, and fine-grained and coarse-grained material washing in water, electricity, construction and other industries. It often cooperates with grinding equipment such as ball mills to form a closed loop, and plays a grading role in various mineral processing production lines.

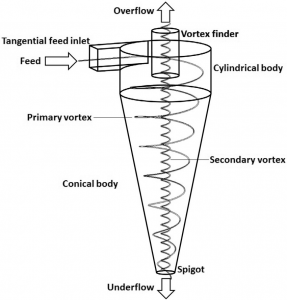

Hydrocyclone is a kind of high-efficiency classification and desliming equipment, which is used to separate and remove heavy and coarse-grained mud sand and other substances in sewage. Because of its simple structure, easy manufacture and large processing capacity, it has been widely used at home and abroad, and sometimes it is also used for mud dewatering. Due to the need for pressurized mining, the power consumption is large, but the area is small, the processing capacity is large, and the classification efficiency is high, and fine overflow products can be obtained.

1. Working principle

The spiral classifier is based on the principle that the size of the solid particles and the specific gravity are different, so the sedimentation speed in the liquid is different. It is a kind of grading equipment that is pushed up by the screw and discharged to the top for mechanical grading. It can filter the material powder ground in the ball mill, and then use the spiral blade to rotate the coarse material into the feed port of the ball mill. The outgoing fines are discharged from the overflow pipe.

The hydrocyclone is a device used to separate and remove heavier coarse-grained silt and other substances in sewage. Sometimes also used for mud dewatering. There are two types of pressure type and gravity type, which are often made of circular cylindrical structures or metal pipes. The water enters tangentially from the upper part of the structure (or metal pipe) by pressure or gravity. Under the action of centrifugal force, the coarse and heavy particulate matter is thrown to the wall of the vessel and rotated downwards and discharged together with the formed concentrate. Smaller particulate matter rotates to a certain extent and is discharged with the secondary upper vortex flow.

2. Applicable materials

Spiral classifier can be divided into two types, namely high weir type and submerged type. The particle size of materials for different types of sorting is different. Among them, the high weir type is mainly for coarse particle sorting, and its sorting overflow particle size diameter is generally greater than 0.15mm; while the submerged type is mainly for fine particle sorting, separating the overflow particle size is generally less than 0.15mm.

Hydrocyclone: It is very good at processing fine-grained materials, and the size range of separating is generally 0.3-0.01mm.

3. Classification efficiency

The spiral classifier rotates at a low speed of the screw to stir the pulp, so that the fine particles are suspended to the top, and flow to the overflow weir to overflow. When the slurry concentration is constant, if the amount of ore fed into the classifier increases, the flow rate of the slurry also increases, thus making the overflow product coarser. When the amount of ore decreases, the particle size of the overflow product becomes finer, and the content of fine particles in the returned sand also increases. Therefore, the ore feeding amount of the classifier should be appropriate and uniform, and it should not be large or small, and the smaller the fluctuation range, the better. Only in this way can the grading machine work under normal processing conditions and obtain a good grading effect.

Hydrocyclone: It has strict pressure requirements, because the hydrocyclone needs to be discharged on the side opposite to the feeding port, that is to say, once the pressure does not meet the standard, the material stratification will be disordered, causing the material to fail. Normal discharge from the discharge port. Generally, its processing capacity is less than 2500m³/h.

4. Equipment price

The maintenance of the spiral classifier is mainly to replace the spiral lining and other daily maintenance. However, because the lining material is more expensive, its purchase and maintenance costs are high. In general, the investment price of a spiral classifier is higher than that of a hydrocyclone.

The equipment price of hydrocyclone is lower than that of spiral classifier. However, in addition to its own equipment, the hydrocyclone requires a series of necessary auxiliary equipment in the grading process, such as distributors, valves, pumps, etc., which increases some equipment investment. In terms of maintenance, the wear parts of hydrocyclones are mainly liners and overflow pipes.

Of course, the frequency and extent of wear is caused by a combination of factors such as material particle size, shape, and solids content. Therefore, its service life and maintenance cost can only be accurately obtained in the actual dressing practice.

Which Equipment Better?

It’s hard to say who has the better separating effect. It depends on your own needs. After all, the equipment suitable for your concentrator is more powerful. for example:

- If the particle size of the sorted material is coarse, it is recommended to use a spiral classifier; if the particle size of the sorted material is small, it is recommended to use a hydrocyclone;

- The requirements on the floor space of the equipment also limit the application of the spiral classifier to a certain extent. If the site area allows, it is recommended to use the spiral classifier. On the contrary, choose a hydrocyclone;

- In terms of separating efficiency and product accuracy, the spiral classifier is better than the hydrocyclone, but it is not absolute. When the particle size of the classification is fine, such as when the particle size of the material is 0.037mm, the sorting efficiency of the hydrocyclone is higher. Significantly higher than the spiral classifier;

The classification equipment cooperates with the grinding equipment in the beneficiation production line to jointly provide ore (material) with suitable particle size for the sorting operation. The selection of any mineral processing equipment will not be decided unilaterally, but must be the result of comprehensive consideration. JXSC will provided that you select a single or multiple grading equipment according to the relevant equipment selection given by the mineral processing test to achieve the ideal grading effect.