Washing & screening Equipment

trommel screen

Capacity: 1-100TPH

Feeding size: <6mm

Application: Sand and gravel aggregate and ore classifying, screening, washing, processing; gold, diamond ore, silica sand, manganese ore, iron ore, quartz sand and other ore with low mud content.

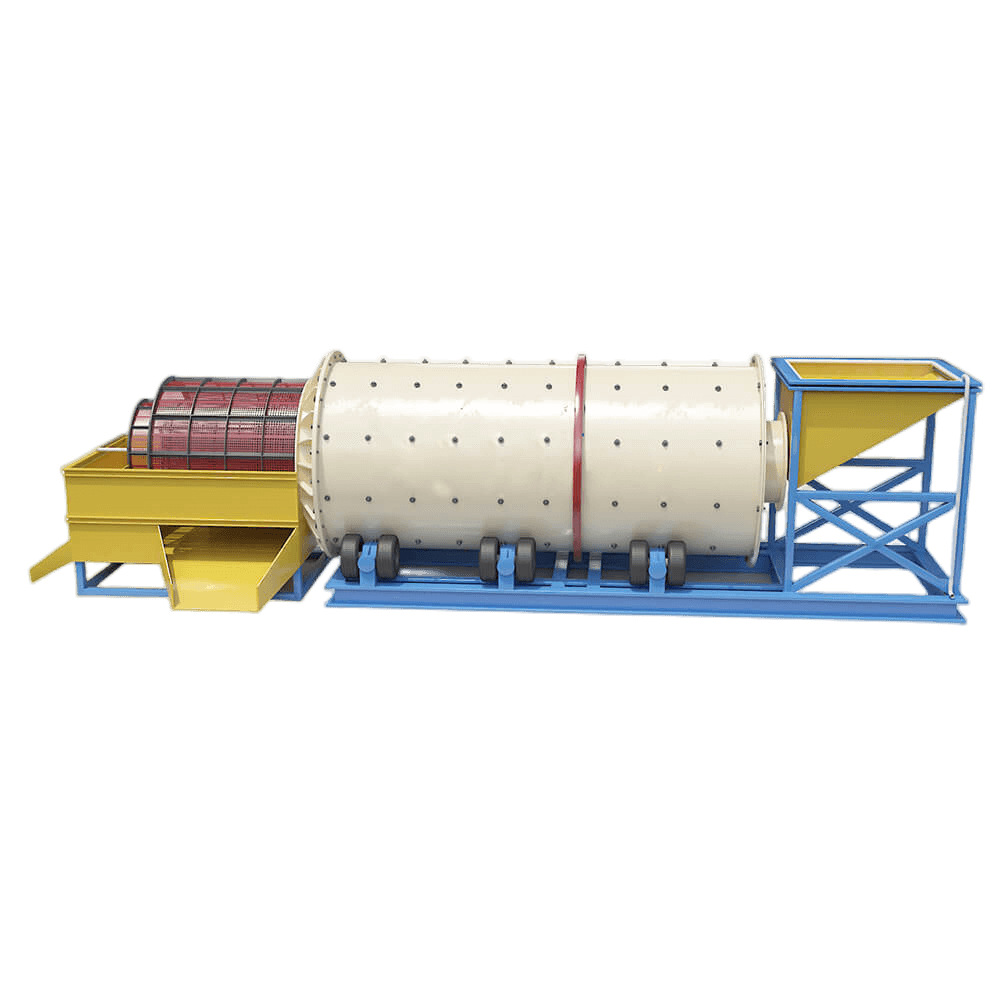

Trommel scrubber

Capacity: 1-200 TPH

Application: It is widely used to wash rock, ore, sand, gravel and aggregates that contain water-soluble clays; effectively wash and screen ore with high mud content and get cleaner products.

Sand washing machine

Capacity: 15-400 t/h

Types: Wheel or Spiral type

Application: quartz sand, limestone, river pebbles, river sand, calcite, aluminum ore and other natural sand and machine-made sand washing; or widely uesd in sand making plant.

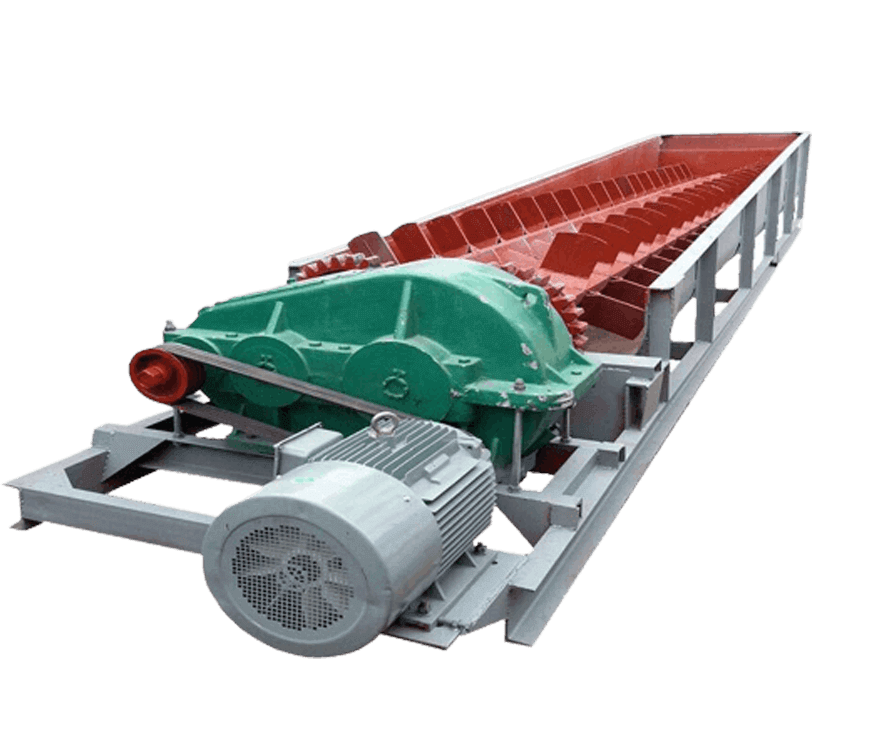

Log washer

Capacity: 1-100TPH

Application: washing of manganese ore, iron ore, phosphate rock, copper ore, barite, hard kaolin, river pebble, granite, basalt, limestone, calcite, quartz stone, diabase and other ores, stones

Attrition Scrubbing Machine

Volume: 1-10 m³

Feeding Size: ≤5mm

Application: scrubbing silica sand(quartz sand), potassium albite feldspar ore, glass sand; ore slime, and removal of impurities on the surface of minerals

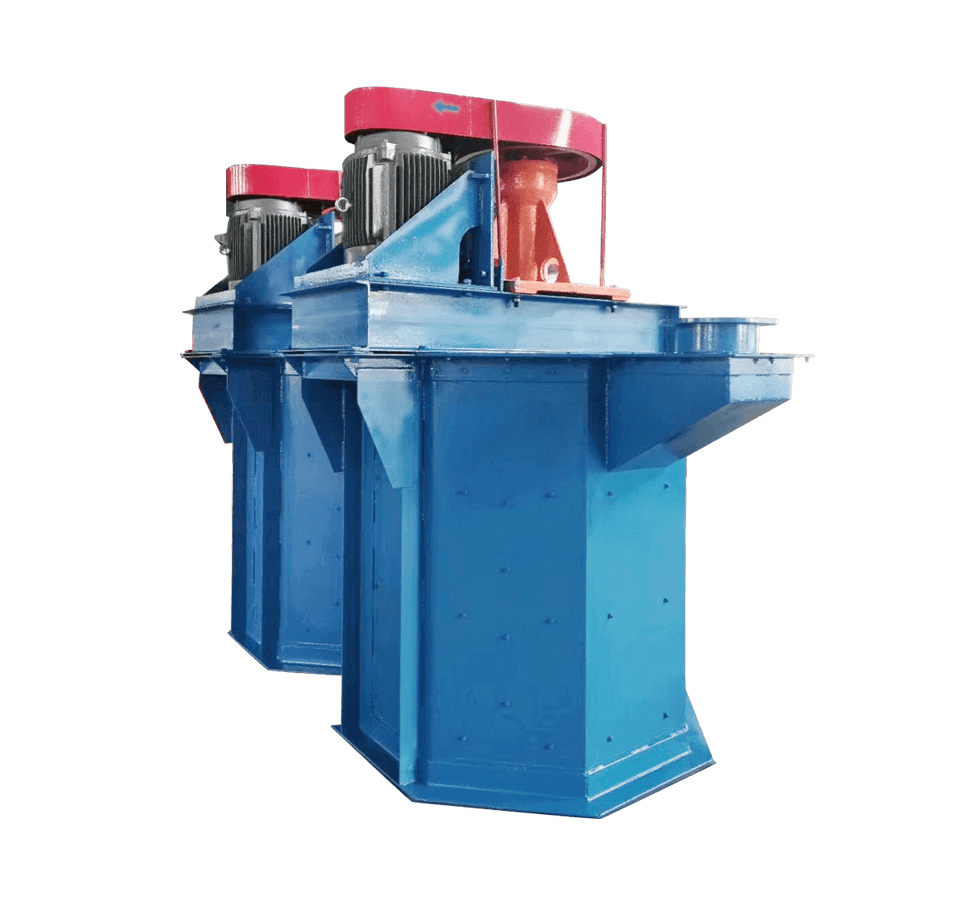

Fine Sand Recycling Machine

Capacity: 30-250TPH

Application: It is mainly used for dewatering and recycling fine sand and fine materials (slurry materials below 0.16mm). It is widely used in sand washing production lines, tailings recycling, silica/quartz sand processing systems, etc.

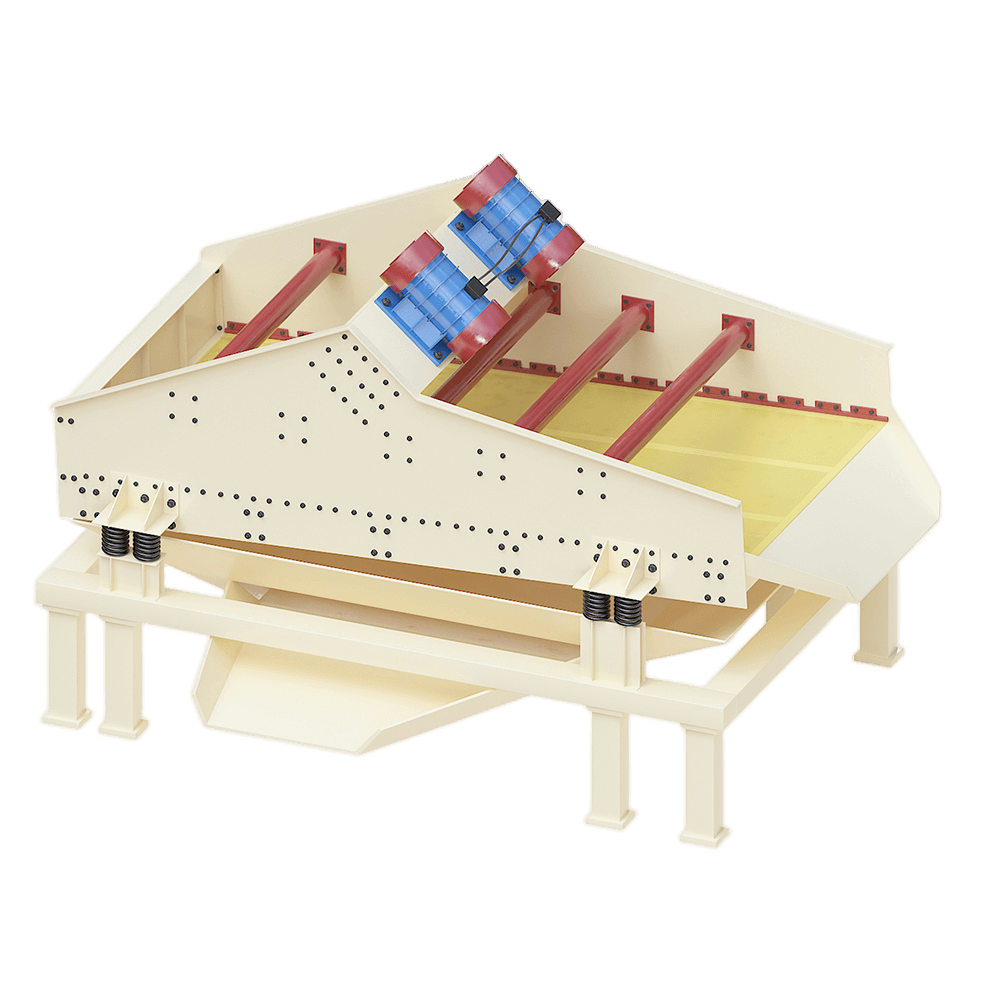

Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

screen mesh: customized

Application: screening rock, sand, gold, copper, manganese, diamond ore, etc.

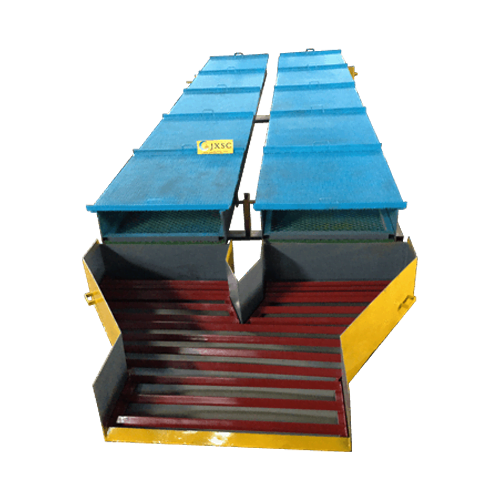

Linear Vibrating Screen

Screen: Multiple discharge holes can be designed

Applicable materials: Classification and screening of various non-sticky, dry powdery materials such as limestone, quartz, gypsum, sand, rocks, aggregates, coal, ores and other bulk solids.

Recommended Products

Contact Us Now

Please fill out the information below for the quotation price and engineer’s help. We will reply ASAP!

Notice:

- We do not provide jobs and have no interest in investment or partnerships.

- We provide mineral processing equipment and solutions; not buy and sell mineral /ore /materials.

- We value your privacy and keep your information safe.