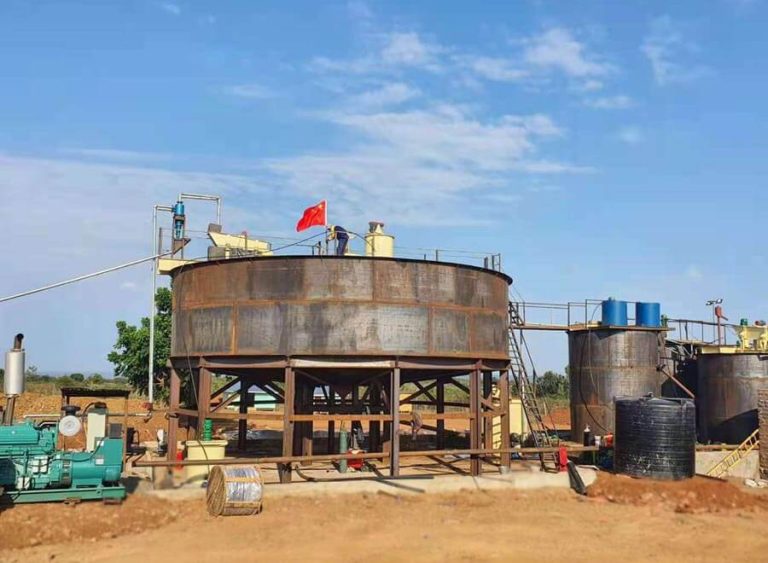

30TPH Alluvial Tin Ore Processing Plant In Uganda

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

1.Raw ore: alluvial tin ore

2.Capacity: 30TPH

3. Feed size: >70mm

4. Output size: 0-2mm

5. Location: uganda

Process

Feeding, washing, gravity separation, dewatering, crushing, screening, magnetic separation

process flow

30TPH Alluvial Tin Ore Processing Plant

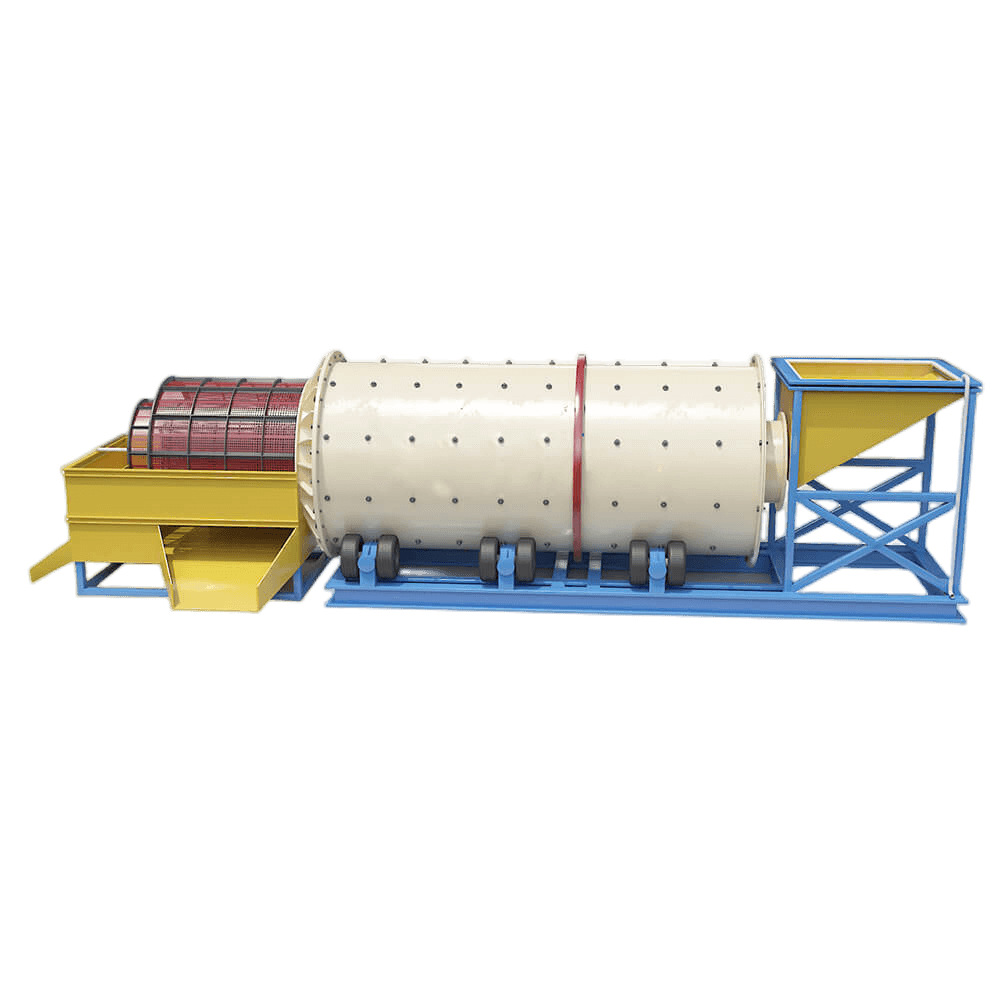

According to the customer’s mineral information and requirements, JXSC have customized a full set of alluvial tin oreprocessing plant and equipment. It is configured with vibration feeder, trommel scrubber, jig separator, dewatering screen, hammer crusher, shaking table, spiral dewatering machine, high frequency vibration screen, 3-disc dry magnetic separator and belt conveyor, etc.

30TPH Alluvial Tin Ore Process Plant Flow Details

1. Feeding & washing stage: vibration feeder, trommel scrubber

The raw ore will be fed into the raw ore hopper above the vibration feeder by excavator or wheel loader etc.The vibration feeder designed with grizzly bar, bar gap is 70mm, which can feed larger than 70mm into a trommel scrubber evenly.

The less than 70mm goes to the trommel scrubber for washing.The trommel scrubber is designed with screen part.(two layers of screen with aperture 7mm and 25mm). Later we can get 3 kinds outputs: 0-7mm, 7-25mm ,and larger than 25mm .

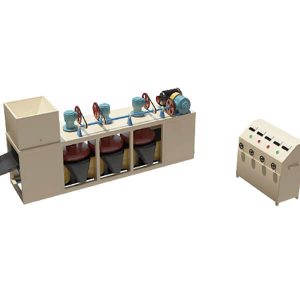

2. Gravity separation: jig separator

After washed by the trommel scrubber, the larger than 25mm will go to the belt conveyor and be sent to the stockpile. 7-25mm will go to one set rough jig separators for 1st coarse tin separation, then the concentrate will go to a cleaner jig separator accordingly for further separation.

0-7mm goes to another rough jig separator for enrichment, then the concentrate will also go to a cleaner jig separator for further separation.The tailings of rough jig separator will go to one scavenging jig for concentrating again.These circled loop jigs here can improve the recovery rate here.

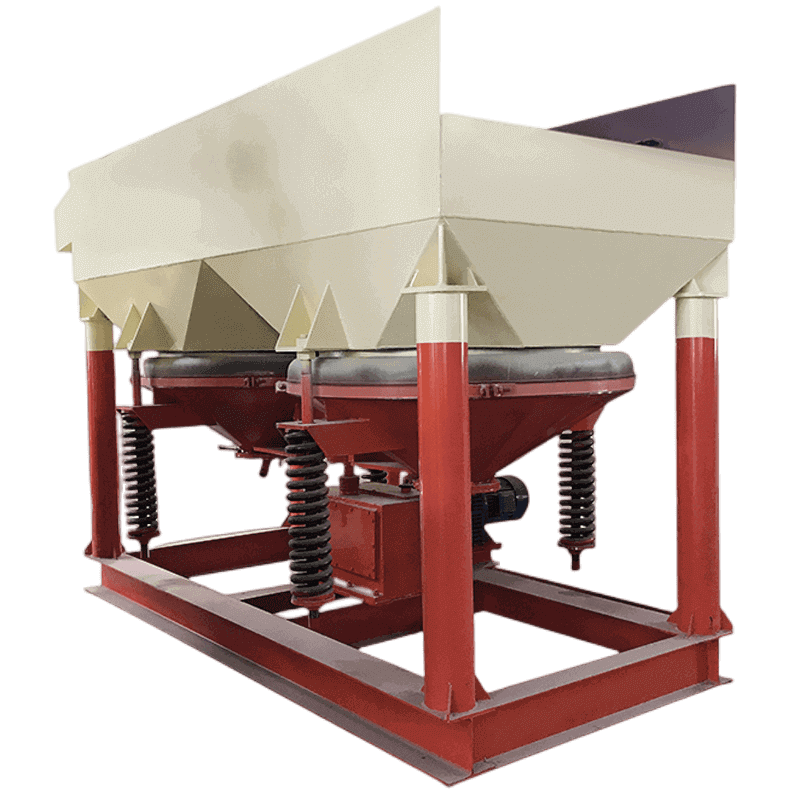

3. Dewatering stage: dewatering screen

All the final concentrates from the jigs will go to a dewatering screen for dewatering first. Because there is a lot of water coming out together with the concentrates.

4. Crushing stage: hammer crusher

After dewatering, then overscreen particles will go to the hammer crusher by belt conveyor. The underscreen will be pumped to a mixing tank by a slurry pump. The output from the hammer crusher will flow into the same agitated mixing tank by gravity flow.

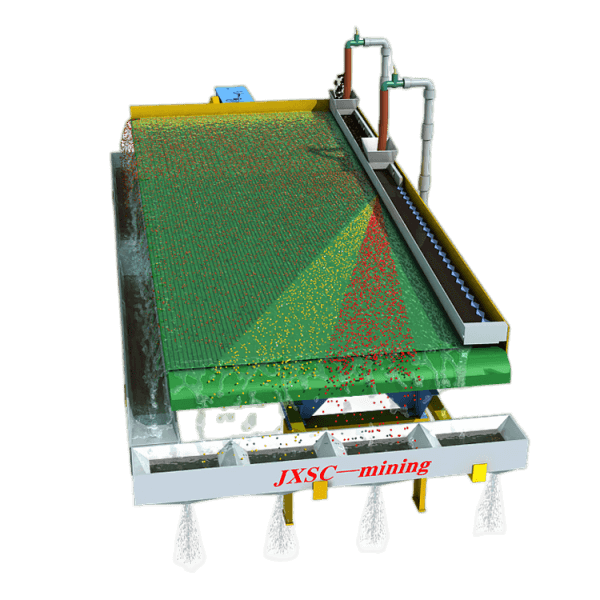

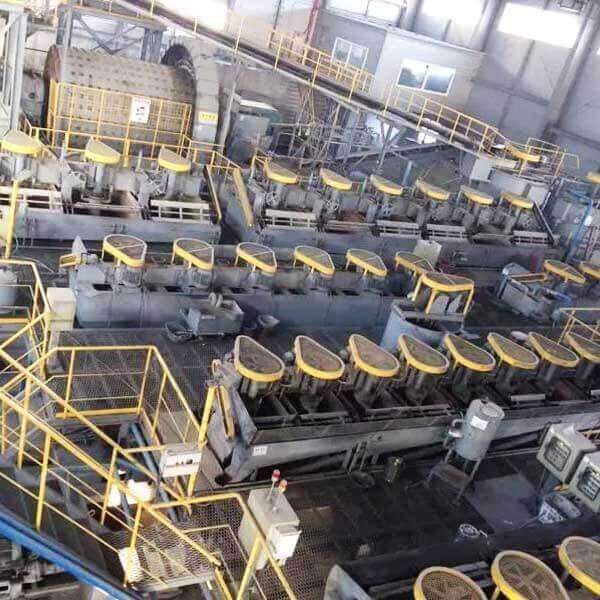

5. Gravity & magnetic separation: shaking table, three disc magnetic separator

The shaking table further separates to obtain a purer tin concentrate. The output concentrate needs to be directly dried, and then the dry concentrate can be put into 3 disc dry magnetic separators for refining to obtain high-purity tin concentrate.

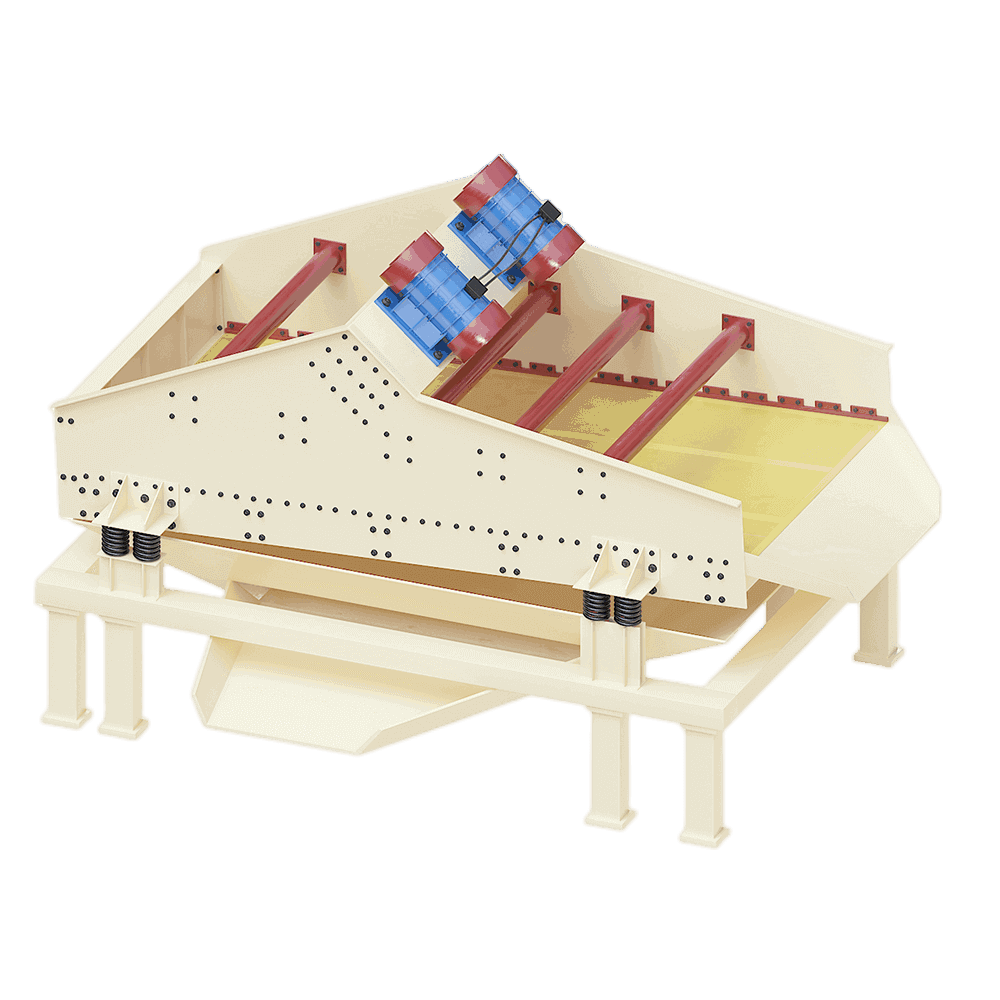

6. Dewatering & Screening: spiral dewatering machine, vibration screen

The tailings from these jig separators and the tailings from the shaking table will first enter the spiral dewatering machine for dewatering, and then enter the high-frequency vibrating screen for screening. Finally, two products of tailings coarse sand and fine sand are obtained.

This plant is designed with high recovery rate. JXSC support customized tin ore processing plant and full equipment according to the mineral characteristics and customer needs. Contact us for more details!

Main Equipment

No. | Equipment name | Model | Quantity |

1 | Hammer crusher | PC400*300 | 1 |

2 | Vibration feeder | DN380*96 | 1 |

3 | Belt conveyor | B650*6m | 1 |

4 | Belt weighting machine | B650 | 5 |

5 | JXSC-900 | 1 | |

6 | Belt conveyor | B650*15m | 1 |

7 | Jig separator | JT4-2 | 3 |

8 | Jig separator | JT2-2 | 2 |

9 | Slurry pump | 2/1.5 inch | 2 |

10 | Belt conveyor | B650*15m | 1 |

11 | Hopper | 1.5*1.5*1.5m | 1 |

12 | BJ-1000 | 1 | |

13 | Spiral dewatering machine | JXSC-XL750 | 1 |

14 | Dewatering screen | JXSC-1536 | 1 |

15 | Belt conveyor | B650*15m | 1 |

16 | Shaking table (Large channel steel) | 4500*1500 | 2 |

17 | Belt conveyor | B650*15m | 2 |

18 | Slurry pump | 10/8 inch | 1 |

19 | Three-disc magnetic sepaarator | 3PC-600 | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.