100TPH Alluvial Coltan Processing Plant In Uganda

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

1. Raw ore: alluvial coltan ore

2. Capacity: 100TPH

3. location: Uganda

4. Input size: <30mm

Process

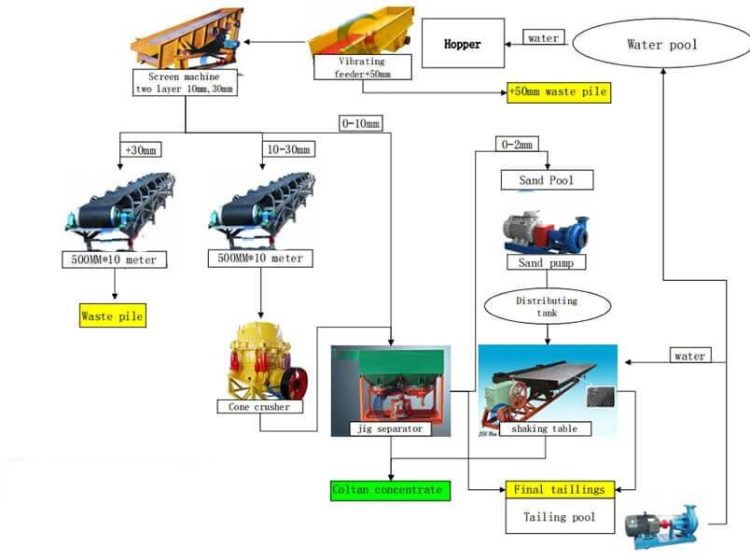

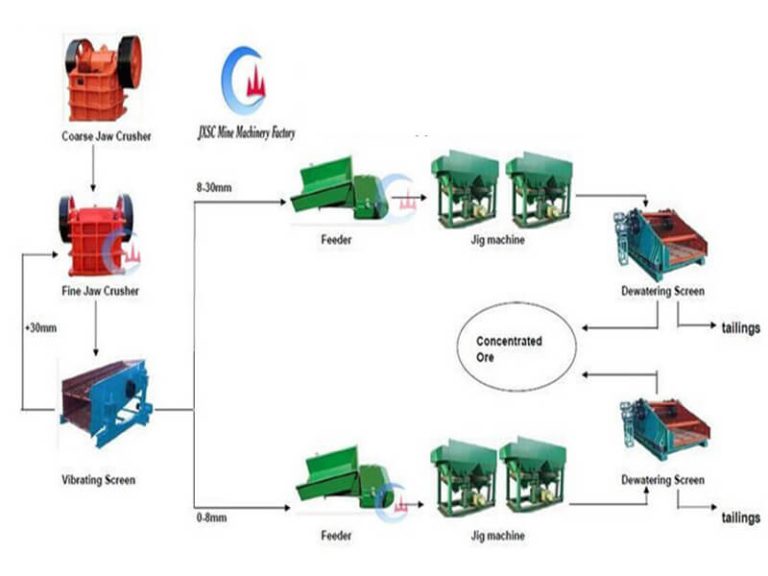

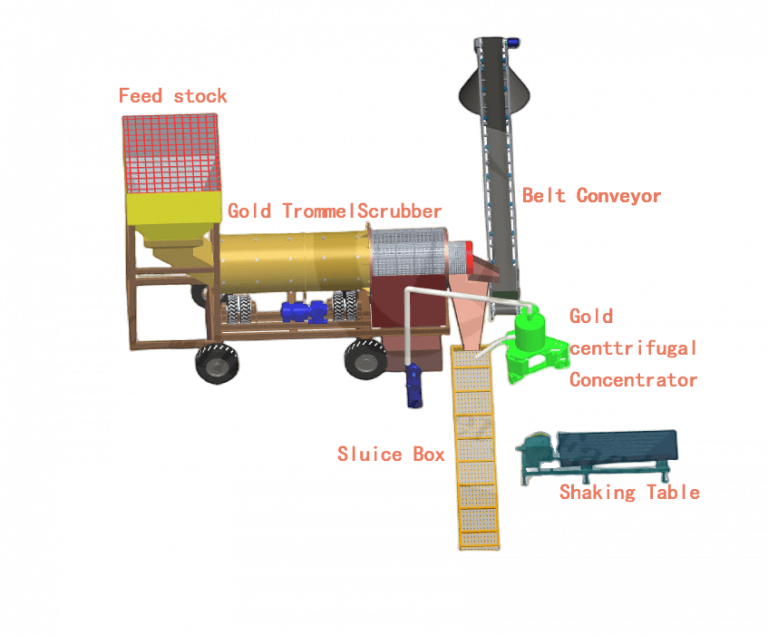

Feeding – Screening – Crushing – Gravity separation

100TPH alluvial coltan processing plant

This full alluvial coltan processing plant is one of JXSC’s most successful cases. From inquiry to installation, our professional engineers solve our customer’s problems the whole way. When customers say our prices are higher than others, we take out equipment to explain why the quality is higher. Product material cost is high, careful workmanship and high labor costs, so the equipment price really can not be less.

After six months of communication, they visited our company and decided to cooperate with us. After the equipment reached the customer’s mine, we sent engineers to guide the site installation.

1. Screening: Vibrating screen

Wash the impurities on the surface of the ore in the hopper with water. The vibrating feeder can evenly feed the coltan-containing ore into the vibrating screen. Vibrating screen with two layers of screens for classifying materials into three grades: +30 mm, 10-30 mm, 0-10 mm.

2. Crushing: Cone crusher

Materials larger than 30mm are transported to one side by a belt conveyor as waste. The 10-30mm material is conveyed to the cone crushing mill to -10mm by a belt conveyor.

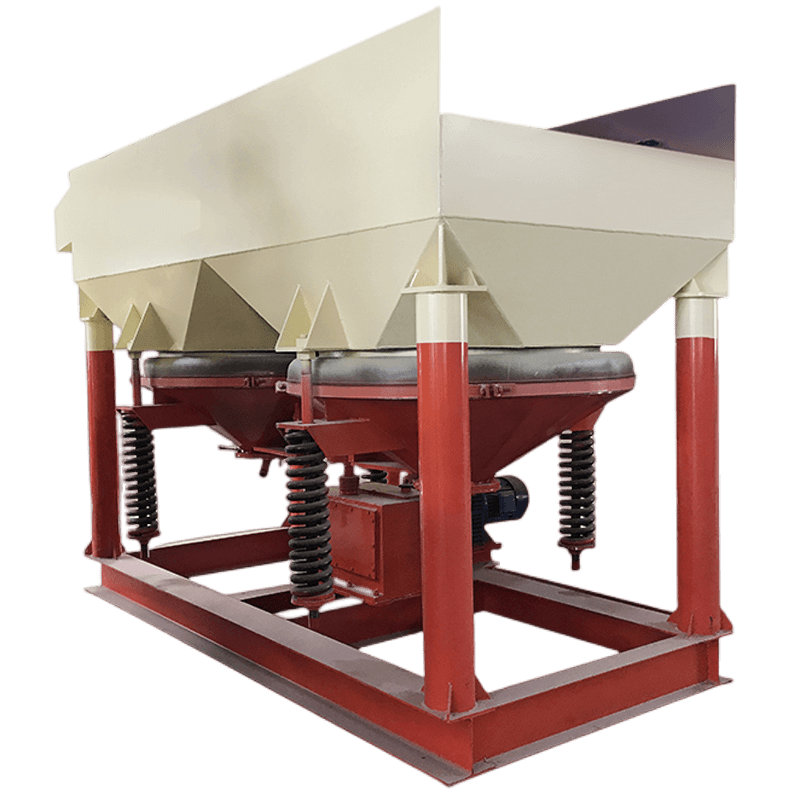

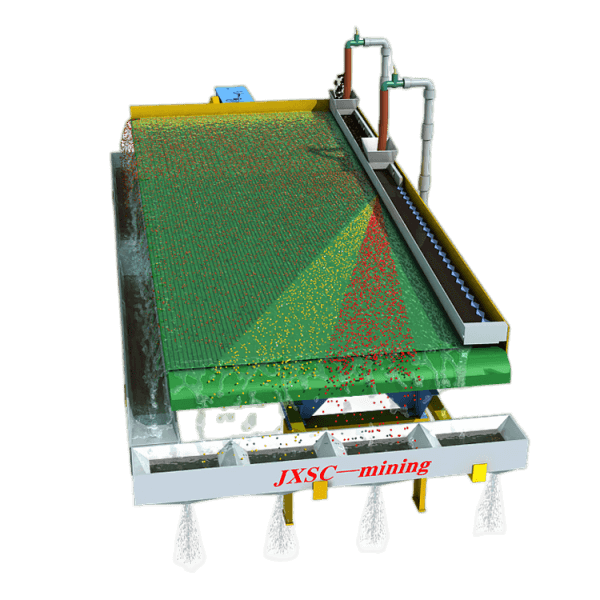

3. Separation: Jig separator, Shaking table

All 0-10mm materials enter the jig concentrator for sorting. +2mm material will generate on sieves. The -2mm coltan concentrate is transported to the distributing tank through a sand pump, and then enters the shaker for re-concentration.

The final tailings enter the tailings pond, and the sand pump is used to transport the water to the shaking table or hopper to clean the sand ore. Water recycling can be realized. JXSC will customize the coltan processing plant and equipment according to the mineral characteristics and customer needs. Contact us for more details!

Main Equipment

100TPH alluvial coltan processing Equipment list

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.