Dredge Pump

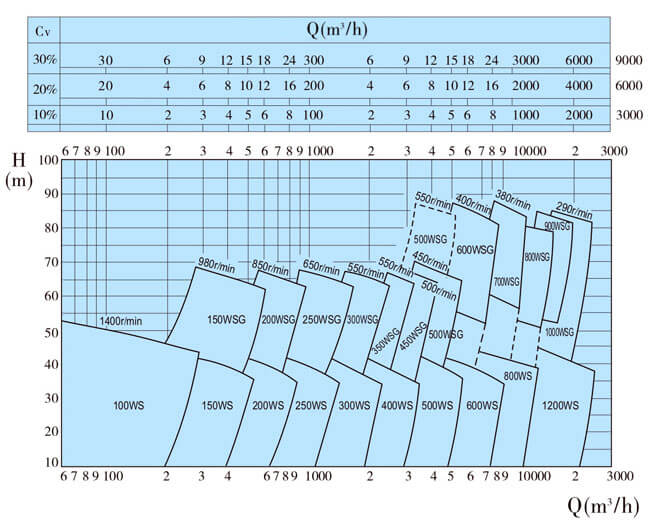

Capacity: 600-25000 m3/h

Size: 8″ to 40″ pump

Head: 20-86m

Handling solids: 0-350mm

Concentration: 0%-70%

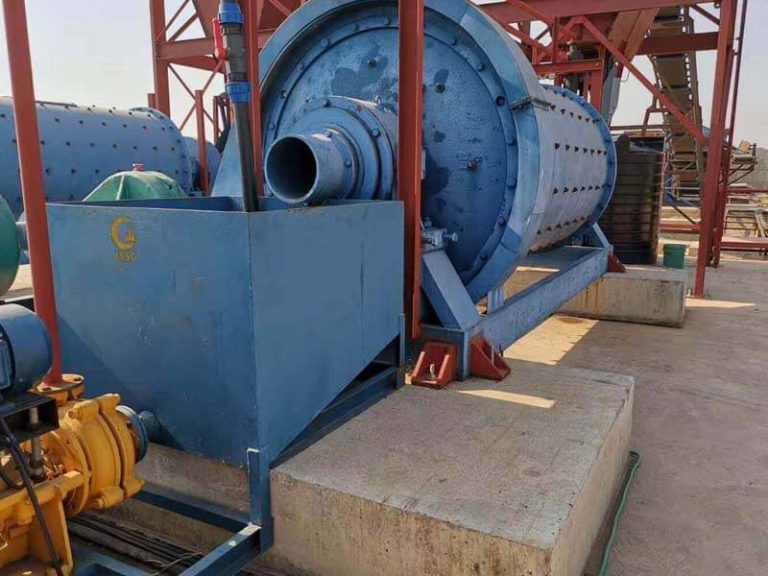

Products display

introduction of dredge pump

Application: WN series dredge pumps are widely used for dredging, cutter suction dredgers, sand and gravel, contract dredging, tailings, booster pump, sand waste pump, material transfer pumps, etc.

features of dredge pump

- WN-type sludge pumps have strong self-priming ability, strong suction height, few parts of the screw pump, compact structure, small volume and simple maintenance. It is a new type of pump made according to the principle of revolving meshing displacement.

- The main working parts of the G-type sludge pump are the eccentric screw (rotor) and fixed bushing (stator). Use non-toxic and tasteless edible rubber; the working temperature can reach 120 degrees Celsius. You can contact us if you use a high temperature of 120 degrees Celsius-350 degrees Celsius.

Due to the special geometric openings of the two components, separate sealed chambers are formed. The medium promotes the flow evenly from the axial direction. The internal flow rate is low, the volume remains unchanged, and the pressure is stable, so there will be no product turbulence and agitation. The output pressure of each pump is 0.6MPa-1.2MPa, the head is 60m-120m (clean water), and the self-priming height is generally above 3m. It can be used as a self-priming sewage pump product.

models & specifications

Model | Capacity Q | Head H | Speed n | Eff. η | NPSH | Inlet Dia. | Outlet Dia. | Max. Particles |

200WND | 600-800 | 20-40 | 700-900 | 60-65 | <4.5 | 250 | 200 | 178 |

200WN | 750-1000 | 40-65 | 700-850 | 70-72 | <4 | 250 | 200 | 180 |

250WND | 950-1100 | 20-40 | 500-700 | 65-70 | <4 | 300 | 250 | 220 |

250WN | 1100-1300 | 40-65 | 500-650 | 70-74 | <4 | 350 | 250 | 144 |

300WND | 1500-1800 | 20-40 | 400-600 | 65-68 | <4 | 350 | 300 | 241 |

300WN | 1800-2200 | 40-65 | 400-550 | 74-78 | <4 | 450 | 300 | 241 |

350WN | 2600-3000 | 40-65 | 400-550 | 74-78 | <4.5 | 450 | 350 | 245 |

400WN | 2800-3200 | 20-40 | 400-550 | 74-78 | <4.5 | 450 | 400 | 250 |

450WN | 3200-3850 | 40-67 | 350-500 | 76-80 | <4.5 | 600 | 450 | 354 |

500WND | 3600-4200 | 20-40 | 220-320 | 72-75 | <4.8 | 600 | 500 | 330 |

500WN | 4500-5500 | 40-65 | 350-450 | 78-80 | <4.8 | 650 | 500 | 250 |

600WN | 5000-9000 | 55-80 | 280-420 | 81-85 | <6 | 660 | 600 | 220 |

700WN | 8000-12000 | 60-85 | 280-380 | 83-85 | <6 | 760 | 700 | 280 |

900WN | 12000-19000 | 50-75 | 280-330 | 85-87 | <6 | 960 | 900 | 320 |

1000WN | 16000-25000 | 23-76 | 181-290 | 85-87 | <6 | 1200 | 1000 | 350 |

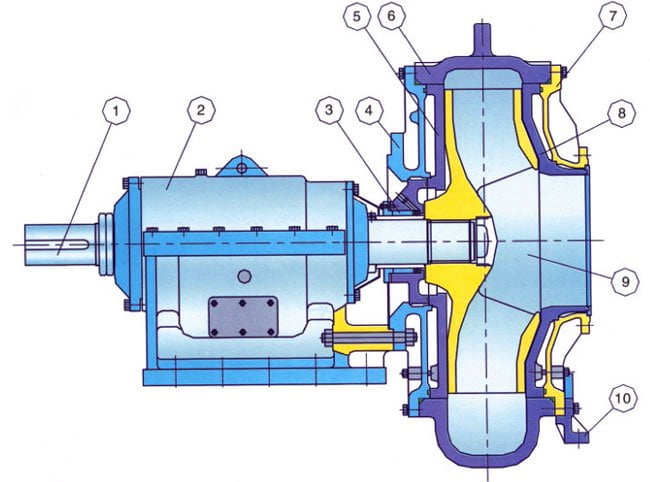

Construction of G Gravel pump

Main Part Number At The Drawing

1 – Shaft

2 – Frame

3 – Mechanical Seal Assembly

4 – Connecting Plate

5 – Rear Liner

6 – Pump Casing

7 – Cover Plate

8 – Front Liner

9 – Impeller

10– Support

Related Products

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.