Flotation machine

Capacity: 0.1-50m³/min per cell

Volume: 0.35-20 m³

Application: Flotation machine is widely used in copper, gold, silver, zinc-lead, nickel, fluorite, antimony ore, molybdenum ore, phosphate ore, lithium, feldspar, talc, iron, graphite, or other mineral processing plants; It can also be used for the separation of ferrous metals and non-metals.

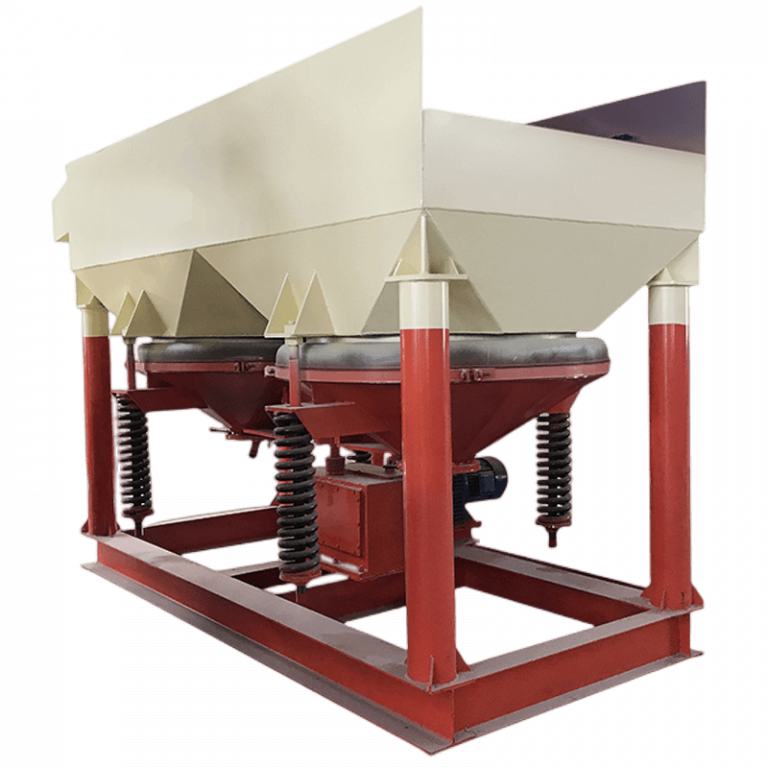

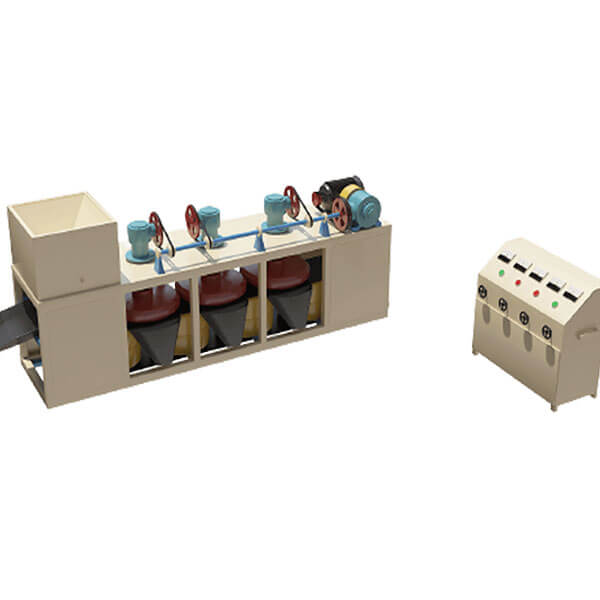

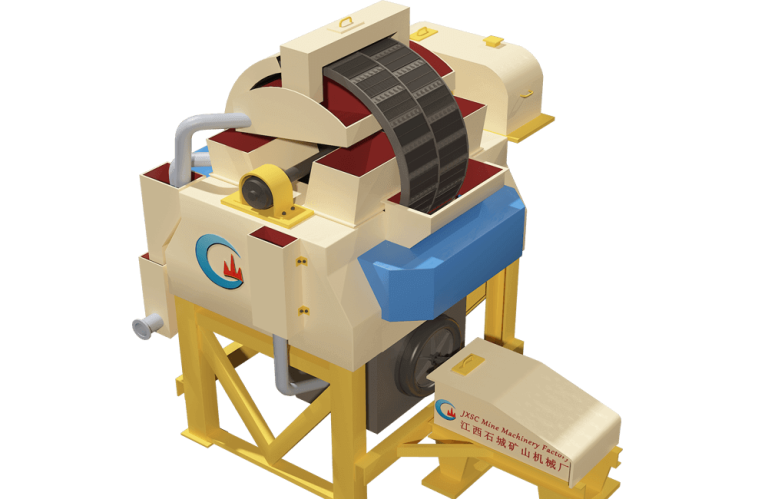

Products display

Introduction of flotation machine

The flotation machine is important for realizing the flotation process. It is suitable for processing fine-grained nonferrous metals, ferrous metals, non-metallic and rare metal ores, and performs particularly well in the separation of complex paragenetic ores and low-grade ores. Such as copper, lead-zinc, lithium, antimony, fluorite, talc, etc. After the minerals undergo wet grinding, the minerals dissociated into monomers are adjusted into a slurry of a certain concentration. It is sent to the flotation equipment after being fully mixed with flotation chemicals in the stirring tank.

JXSC flotation machine has a large air suction volume and low power consumption. It can realize the selective separation of polymetallic ores such as copper-lead-zinc, sulfur-iron, etc., and can increase the copper ore with a raw ore grade of 0.3% to more than 25% of the concentrate. The flotation machine is a key mineral separation equipment in the field of efficient recovery and beneficiation of complex polymetallic ores.

Core functions of flotation machines

- Precious metal ore: extraction of metals such as gold and silver.

- Non-ferrous metal beneficiation: sulfide ores and oxide ores such as copper, lead-zinc, molybdenum, and nickel.

- Ferrous metal separation: flotation and purification of iron ore, manganese ore, chromite, and ilmenite.

- Rare metal recovery: flotation and enrichment of spodumene, tantalum-niobium ore, lithium, and rare earth ore.

- Non-metallic ore processing: selection of fluorite, phosphate rock, graphite, etc.

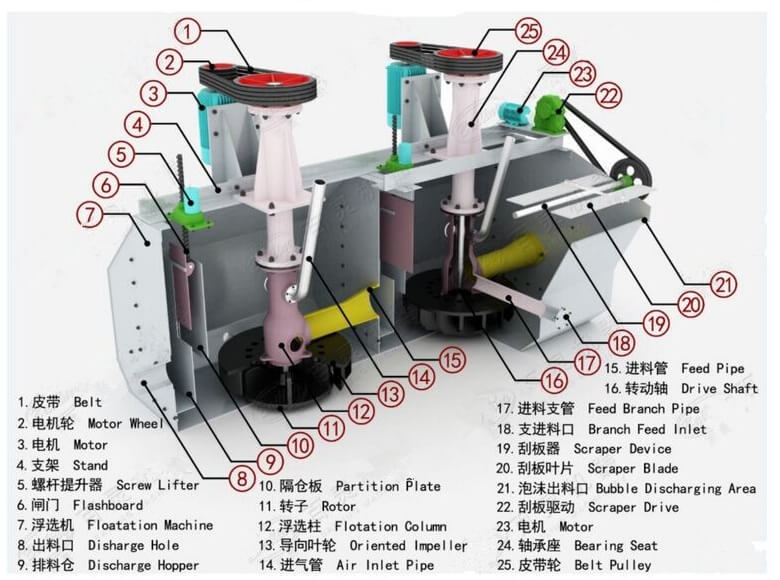

Principle & Structure of flotation machine

Work principle

The flotation machine operates based on the principle of differences in the hydrophobicity of mineral surfaces: First, the crushed ore is mixed with water and flotation reagents to form a slurry, which is then fed into the flotation tank. Air is introduced through a stirring device, creating numerous tiny bubbles. The target minerals, modified by the reagents, exhibit hydrophobic surfaces and actively adhere to the bubble surface, rising to the surface to form a foam layer. Hydrophilic gangue minerals remain in the slurry. Finally, the foam layer enriched with the target minerals is scraped off by a scraper to obtain the concentrate, while the remaining slurry is discharged as tailings, completing the mineral separation process.

Structural Characteristics

- Pulp Tank: Contains the slurry, available in direct-flow and suction designs. Most are constructed from welded wear-resistant steel plates and equipped with a level control device to stably control the slurry level.

- Agitation System: Consists of a motor, transmission components, impeller, and stator, ensuring uniform slurry suspension.

- Aeration System: Introduces air into the slurry via a blower or compressor, providing controlled air bubbles.

- Scraper Device: A continuous scraper mechanism driven by a motor, periodically scraping away concentrate foam from the surface.

- Reagent Addition System: Precisely adds flotation reagents via metering pumps or pipelines, ensuring thorough mixing between reagents and slurry.

- Control System: Employs a PLC or intelligent control system to monitor flotation process parameters (such as pH, aeration rate, and agitation speed) in real time, achieving automated operation.

Types Of flotation machine

Flotation machines For Sale

There are three main types of JXSC flotation equipment, namely mechanical agitation flotation machines (SF, GF, BF, JJF type), inflatable agitation flotation machines (XCF type, KYF type), and inflatable flotation machines (XJB rod flotation machine).

During the flotation process, the reagents and the ore pulp to be selected are mixed and then put into the flotation equipment. After the stirring and aeration of the flotation machine, the bubbles and the ore particles are contacted, collided, and adhered to achieve the final mineralization. The target minerals float up with the bubbles to the surface of the ore pulp and become a foam layer, which forms the flotation concentrate; it is discharged from the flotation machine by scrapers or gravity. Non-target minerals are retained in the ore pulp area and discharged from the tank.

How to choose a model? JXSC supports custom flotation equipment and gets 100% factory price details!

why choose JXSC Flotation machine

features & Advantages Of Flotation machine

√ High-efficiency separation: For low-grade ores with fine-grained disseminated particles, it can achieve a mineral recovery rate of over 90%, significantly improving concentrate grade and economic benefits.

√ Energy saving and consumption reduction: Adopting a high-efficiency impeller structure design, it saves 20%-30% of electricity compared to traditional flotation machines of the same specifications, greatly reducing long-term operating power costs.

√ Strong adaptability: It can process ores of different particle sizes and properties, including refractory ores and metallic and non-metallic minerals.

√ High degree of automation: Equipped with an advanced control system, it reduces manual intervention and improves production stability.

√ Durable and reliable: Core components are made of wear-resistant rubber and special alloy materials, with strong resistance to slurry erosion and reagent corrosion, extending the service life of the equipment.

√ Environmentally friendly and low-pollution: The JXSC flotation machine is designed for low-noise operation, meeting modern environmental protection requirements.

√ Modular design: Supports multiple cells in series or parallel, flexibly adjusting the production scale to adapt to different capacity requirements.

√ Easy maintenance: Key components adopt a quick-disassembly structure, facilitating maintenance and replacement, reducing downtime, and improving production efficiency.

√ Customizable: Multiple mechanical and aerated flotation equipment are available. By adjusting parameters such as reagent formulation, stirring intensity, and aeration volume, etc. It can be adapted to the continuous production needs of large-scale concentrators with a capacity of tens of millions of tons.

models & specifications

Model | Volume | Cell size | Impeller Dia. | Impeller speed | Capacity | Power | Singe cell weight |

m3 | mm | mm | r/min | m3/min | kw | kg | |

XJK-3A | 0.35 | 700×700×700 | 300 | 483 | 0.18-0.4 | 2.2/0.55 | 430 |

XJK-4A | 0.62 | 820×900×850 | 350 | 400 | 0.3-0.9 | 3/1.1 | 755 |

XJK-5A | 1.1 | 1100×1100×1000 | 500 | 330 | 0.6-1.6 | 5.5/1.1 | 1416 |

XJK-6A | 2.8 | 1750×1600×1100 | 600 | 280 | 1.5-3.5 | 11/1.1 | 2113 |

XJK-7A | 5.8 | 2200×2200×1200 | 750 | 240 | 3–7 | 22/1.5 | 3400 |

SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9828 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.