Gold Centrifugal Concentrator

Capacity: 0.5-60 TPH(ton per hour)

Feeding size: 0-6mm

Application: The centrifugal concentrator is widely used for the gold recovery of alluvial gold, vein gold ore, and polymetallic ore, and separating tailings; it can also be used for the beneficiation of gold-bearing heavy sand washed by chute and gold dredger.

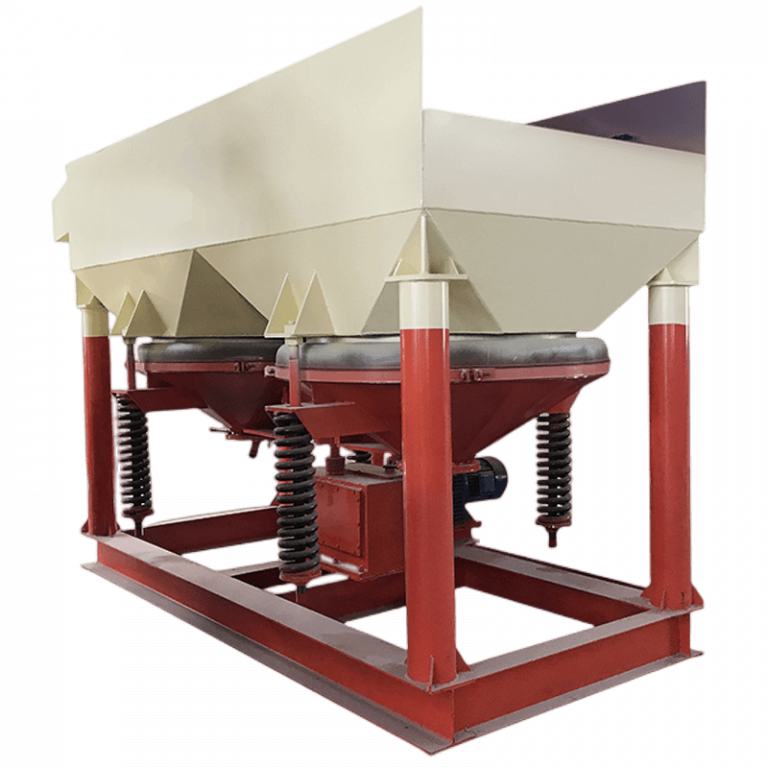

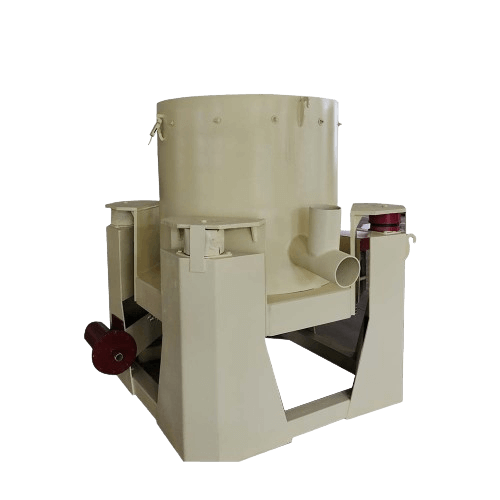

Products display

introduction of gold Centrifugal Concentrator

The gold centrifugal concentrator rotates at a high speed, generating a high “G” force, which can separate small gravity recovery gold (less than 50 microns). It is a highly efficient mineral separation equipment that integrates sorting, extraction, and concentration. The centrifugal concentrator is widely used in the beneficiation process of gold, tungsten, tin, and other metal and non-metallic minerals. It can also recover the tailings of gold, chromite, scheelite and other heavy minerals. So as to make better use of the mineral concentrate. Centrifugal concentrators are mainly used for placer gold mining and rock gold beneficiation, such as river alluvial gold and seashore gold placer concentrating, vein gold ore gravity separation or tailings reprocessing.

With its low cost, high recovery, separation, and enrichment of fine minerals, it has become an irreplaceable core gravity separation equipment in modern gold beneficiation, especially suitable for low-grade resources and environmentally friendly gold extraction plant. The centrifugal concentrator can be equipped with a shaking table and is designed to be mobile type so that it can be moved between different mines, especially for small-scale mines and mobile gold mining projects. It can efficiently concentrate the processed ore, support continuous operation, reduce the subsequent processing costs, and extract valuable metal minerals without increasing secondary pollution.

working principle & structure of Centrifugal Concentrator

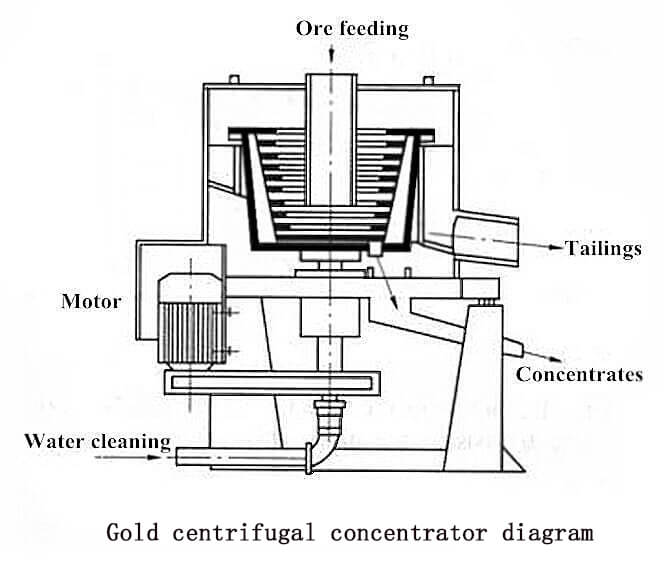

working principle

Gold centrifugal concentrator is a gravity enhancement device. The powerful centrifugal force generated by the high-speed rotation of the centrifuge rotor is used to accelerate the settling speed of particles in the liquid. It mainly separates materials with different sedimentation coefficients and buoyancy densities in the materials.

Heavy minerals precipitate on the inner wall of the drum and become concentrate, which rotates with the drum. The light minerals are washed away on the surface of the concentrate layer along the slope of the drum and become tailings; they flow into the ore receiving trough and then flow into the tailings trough through the ore discharge separator.

Structural features

The design of a centrifugal concentrator usually includes a rotating cylinder, a feed port, a discharge port and a concentration tank, with a compact structure and simple operation. Its working mode is mostly intermittent circulation (feeding-sorting-discharging concentrate-washing), and some models support continuous operation.

- Transmission system: driven by a motor through a belt or gear reducer. Some high-end models use variable frequency speed regulation to achieve precise speed control.

- Ore discharge and flushing system: The intermittent model uses program-controlled high-pressure flushing water to flush the ore regularly, and the concentrate is discharged from the bottom discharge port. The continuous model uses the annular slit at the bottom of the drum or the “bottom flow-overflow” double outlet design to achieve uninterrupted ore discharge.

Why Choose JXSC Gold Centrifugal Concentrator

features & Advantages

1. Leading recovery rate: The recovery rate of micron-sized minerals is 85%-98%, far exceeding other gravity separators, especially suitable for difficult-to-recover minerals such as colloidal gold and fine-grained cassiterite.

2. High enrichment ratio: The recovery rate of placer gold is more than 95%, the recovery rate of vein gold monomer gold is 98%, the concentrate and tailings are continuously produced, and the concentrate output rate is high.

3. Convenient operation: Equipped with a PLC control system (some models), the drum speed, flushing volume and sorting parameters can be adjusted in real time. The operation is simple and intuitive, which is convenient for staff to monitor the progress of the operation at any time.

4. High degree of automation: It can adapt to minerals of different densities through frequency conversion speed regulation, realize the addition and discharge process without manual intervention, and enhance safety.

5. Small footprint: The equipment has a compact design structure and small space occupation, which is suitable for a small production environment and has a relatively low investment cost.

6. Flexible configuration: It is often combined with gold mine drum scrubbers, drum screens, shakers, chutes and other mineral processing equipment for placer gold beneficiation plants.

7. Low consumption and environmental protection: No chemical agents are required, water consumption is low, and the water recycling rate is >80%, which reduces operating costs.

models & specifications

Model | Capacity (t/hr) | Feeding Size(mm) | Feeding Density(%) | Power Requirement (kw) | Cone Rotate Speed | Back Water Required(m3/h) | Dimension(mm) |

STLB20 | 0.5-1 | 0-2.5 | 20-50 | 1.1 | 800 | 15 | 800*560*710 |

STLB30 | 2-3 | 0-4 | 20-50 | 2.2 | 600 | 20 | 1280*1030*1135 |

STLB60 | 8-12 | 0-6 | 20-50 | 7.5 | 460 | 50 | 1850*1550*1600 |

STLB80 | 10-20 | 0-6 | 20-50 | 15 | 400 | 80 | 2300*1800*2200 |

STLB100 | 40-60 | 0-6 | 20-50 | 18.5 | 360 | 100 | 2400*2400*2250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.