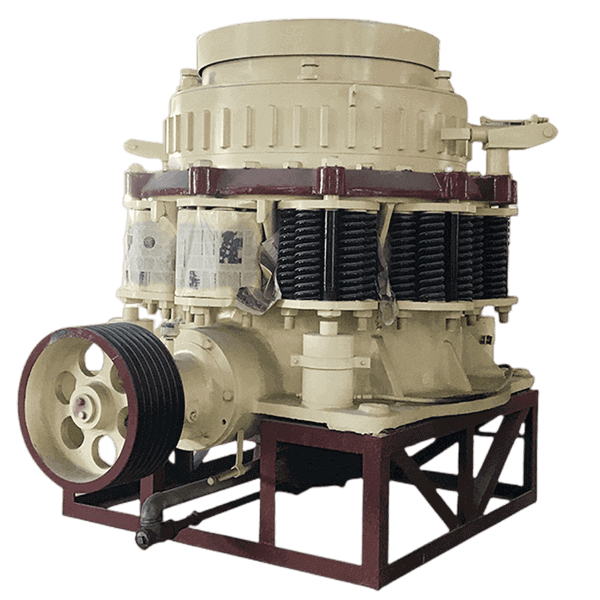

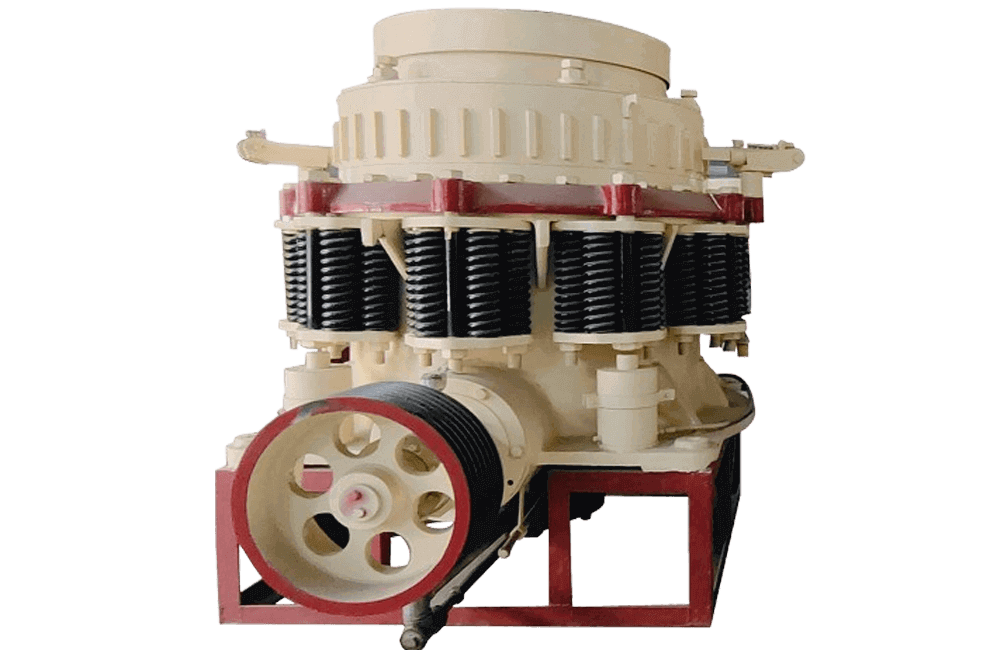

symons cone crusher

Capacity: 27-1450 t/h

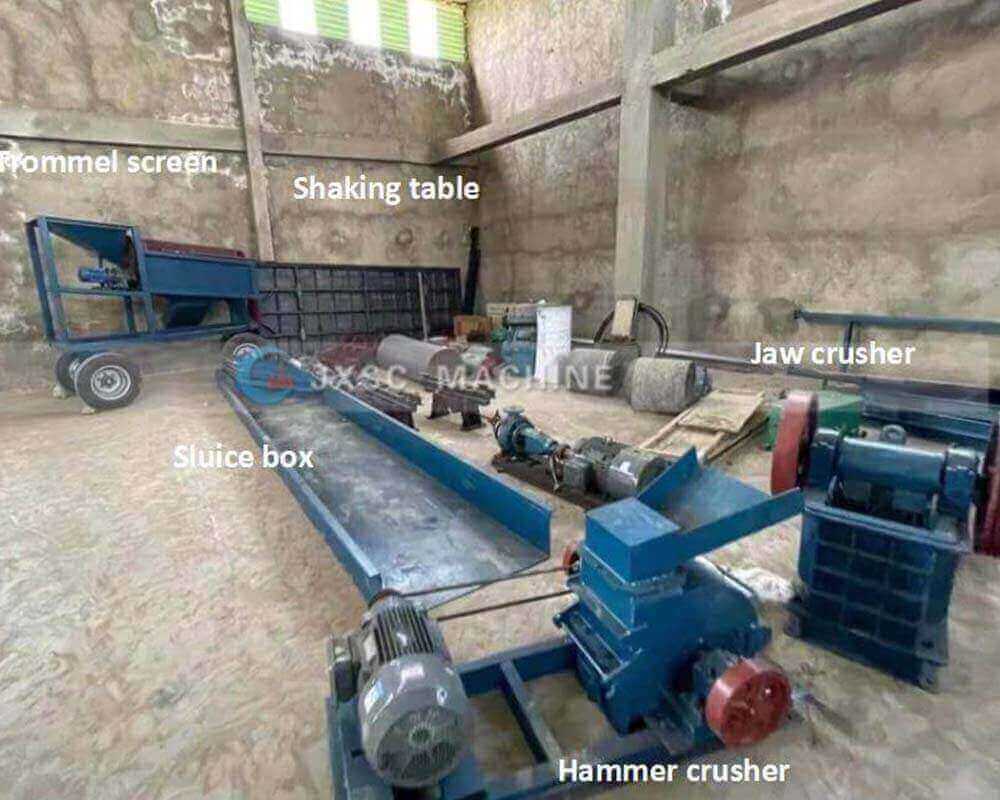

Application: Symons cone crusher is widely used in metal and non-metallic mines, cement plants, construction, sand and gravel aggregates, machine-made sand production and other industries. Especially suitable for crushing hard and medium-hard ores and rocks such as gold ore, non-ferrous metal ore, copper, manganese, lithium, iron ore, tantalum niobium, chromite, diamond, andesite, granite, basalt, diabase, quartzite, etc.

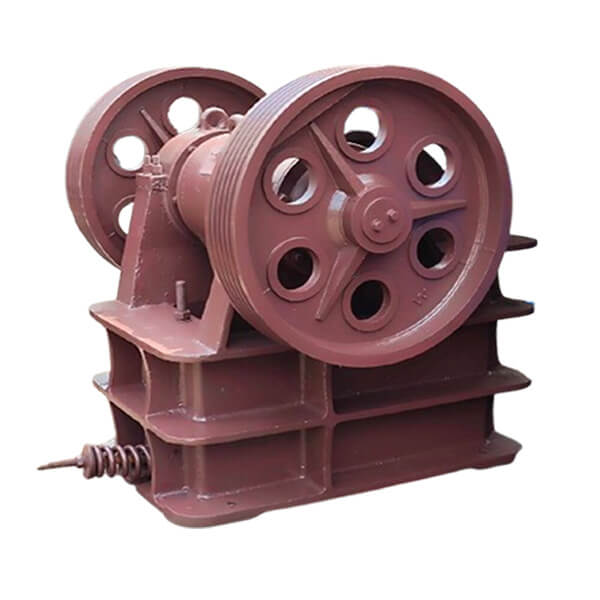

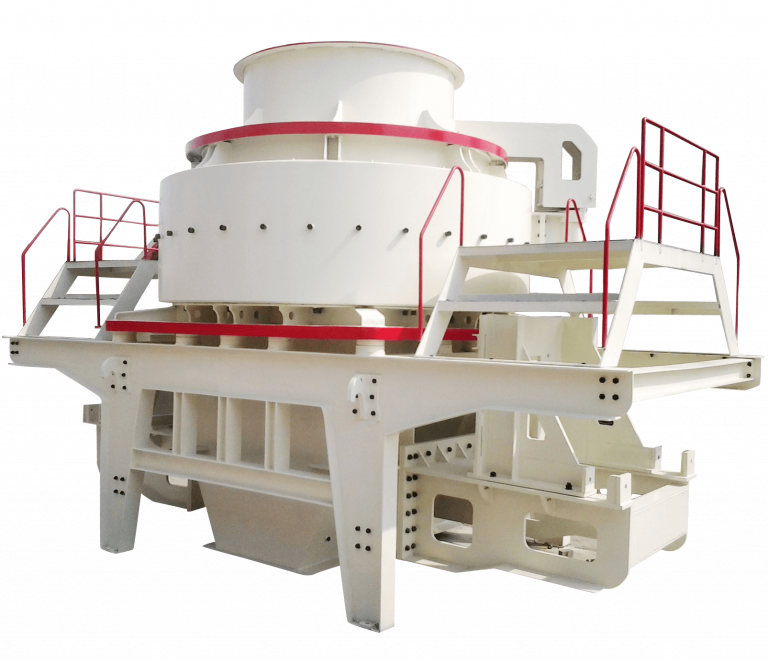

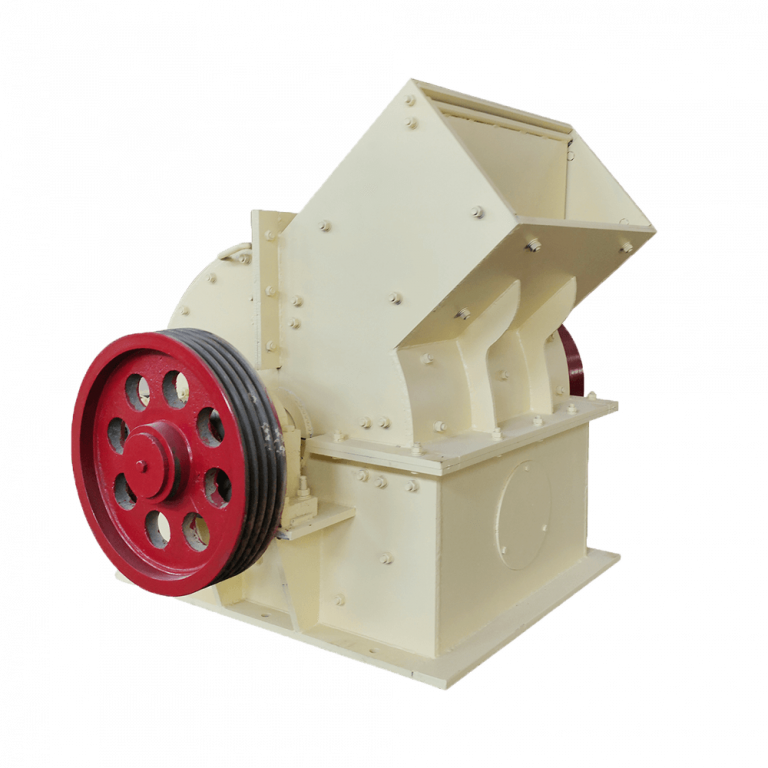

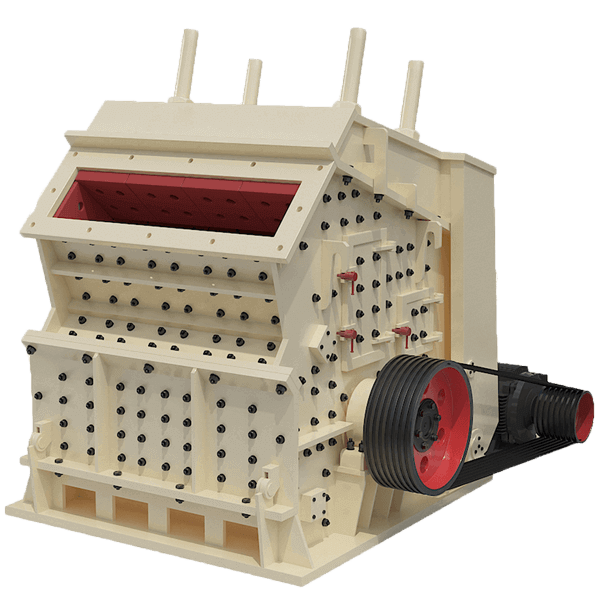

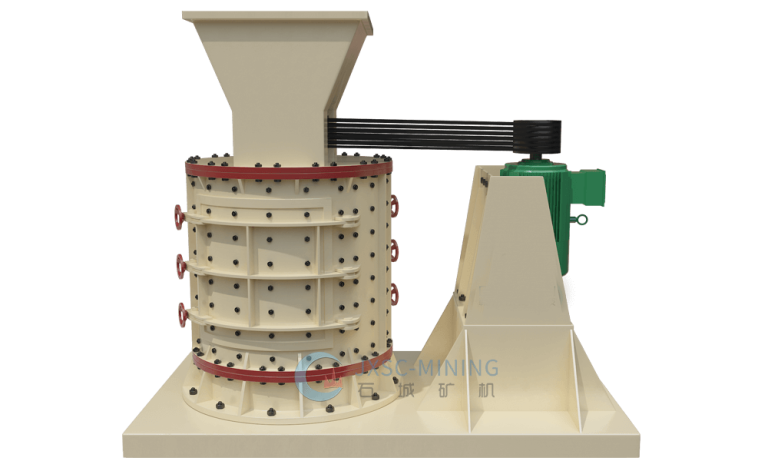

Products display

Introduction of symons cone crusher

Symons cone crusher is a spring cone crusher, also known as compound cone crusher. It is a modern high-performance cone crusher based on the principle of laminated crushing, integrating high swing frequency, optimized cavity type and reasonable stroke. It is often used to crush hard materials such as granite, basalt, quartz stone, limestone, etc. It not only has high efficiency and low production cost, but also has good particle shape and high quality of the finished product after crushing. It is also used in the beneficiation process of precious metals, new energy mines, ferrous and non-ferrous metals.

The core features of Simmons cone crusher are the integrated spring safety system and laminated crushing principle, which is suitable for medium and fine crushing of ores with medium or higher hardness (Mohs hardness 6-16).

It can effectively reduce the particle size of the ore entering the mill, achieve more crushing and less grinding, and greatly improve the economic benefits of the beneficiation plant. Symons cone crusher has won the trust of users around the world with its large processing capacity, excellent particle shape, high degree of automation, and low maintenance cost. It is an improved, optimized, and upgraded alternative to the traditional cone crusher; the most common crushing equipment for building materials such as sand, stone and brick.

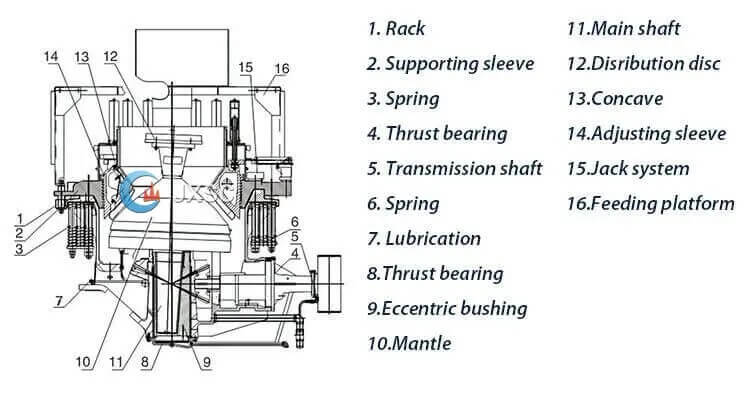

working principle & structure of symons cone crusher

Working principle

The motor drives the eccentric sleeve to rotate through the V-belt, large pulley, transmission shaft, small bevel gear and large bevel gear. The axis of the crushing cone rotates and swings under the force of the eccentric sleeve, so that the surface of the crushing wall sometimes approaches and sometimes leaves the surface of the mortar wall, so that the material is continuously impacted, squeezed and bent in the annular crushing chamber composed of the fixed cone and the moving cone and crushed.

After multiple extrusions, impacts and bends, the material is crushed to the required particle size and discharged from the bottom.

Structural features

- Multiple cavity design: provide standard, short head and medium cavity options.

- Strong shell structure: high-strength steel, durability and impact resistance.

- Hydraulic adjustment system: convenient discharge port adjustment.

- Overload protection device: ensure the safe operation of the equipment under high load.

- Simple maintenance design: easy to disassemble, repair and replace parts.

why choose JXSC symons cone crusher

features & Advantages

1. Large crushing ratio, high production efficiency, large output, strong reliability; high degree of automation, reduced downtime;

2. A variety of crushing chamber types can be selected, which can be used for coarse and medium crushing of various high-hardness and low-hardness materials, with a wide range of applications;

3. The laminated crushing principle is adopted, the product shape is cubic, the needle-like stones are reduced, and the particle size is more uniform and better;

4. The hydraulic cavity cleaning system can quickly clean the crushing cavity, greatly reducing downtime;

5. The automatic control system adopts a large-diameter main shaft, a heavy-duty main frame and an independent thin oil lubrication system, which is durable and stable in operation;

6. All components can be disassembled from the top or side, and sliding bearings are used, which is more economical and convenient for maintenance;

7. When non-crushed objects such as iron blocks enter the machine, the “spring-type” iron protection device will automatically release it and then automatically reset it.

models & specifications

Model | Crushing Cone Dia(Feet) | Max feeding size(mm) | Discharge size range(mm) | Main machine power(KW) | Process capacity(T/H) |

DN900 | 3′(914) | 50-163 | 10-38 | 75 | 27-140 |

DN1200 | 4′ | 80-180 | 16-50 | 132 | 80-250 |

DN1300 | 4.25′(1295) | 70-238 | 10-51 | 155 | 50-360 |

DN1600 | 5.5′(1676) | 90-331 | 10-64 | 240 | 100-630 |

DN2100 | 7′(2134) | 120-425 | 13-64 | 315-400 | 300-1450 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.