Roller Crusher

Capacity: 1.5-70t/h

Feeding size: <50mm

Application: Roller crusher is widely used in crushing limestone, river pebbles, coal, granite, weathered rock, basalt, quartz stone, cement clinker, coal gangue, gold, quartz sand, feldspar, iron ore, manganese ore, limestone, dolomite, gypsum, talcetc.

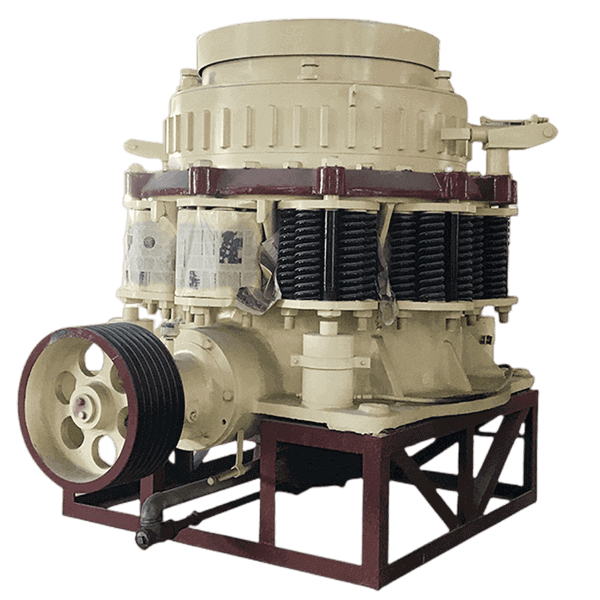

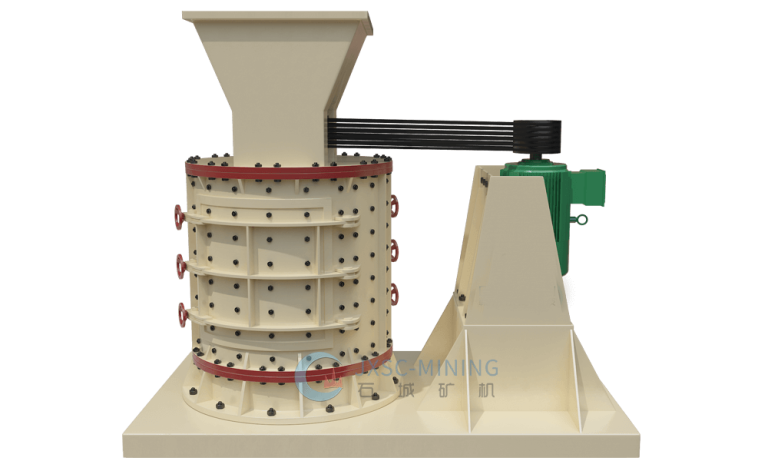

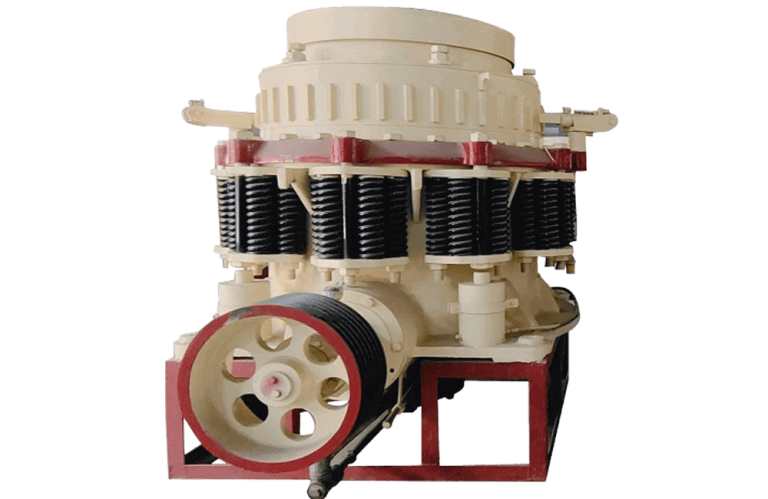

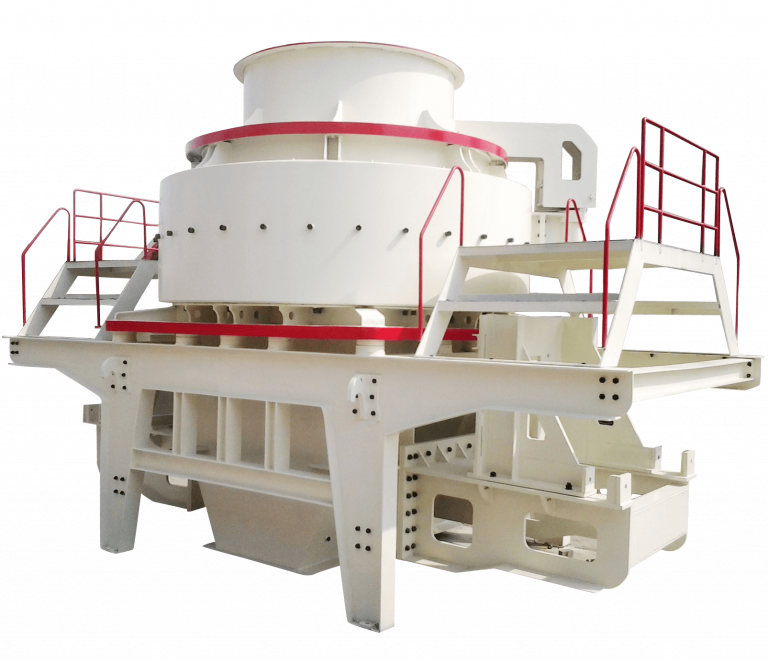

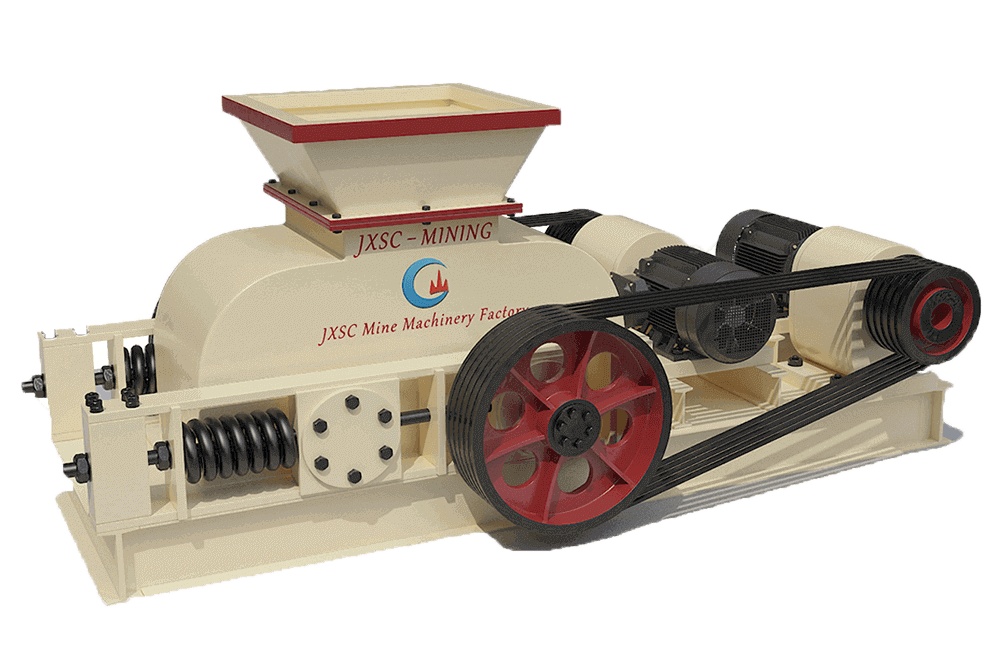

products display

introduction of roller crusher

The roller crusher, also known as a double roll crusher or spring roller crusher, is suitable for coarse and intermediate crushing of brittle and massive materials in various industries, including cement, the chemical industry, electric power, mining, metallurgy, building materials, refractory materials, and coal mines. The granularity is adjustable, which can crush the material with vertical compression strength ≤160MPa. It is mainly used to crush limestone, gypsum, shale, iron ore, manganese ore, and other low and medium-hardness materials, especially good at processing sticky or high-humidity (water content ≤ 20%) materials.

Especially in the coal industry, using this roll crushing machine to crush raw coal, it can be directly crushed only after removing iron, impurities, and without gangue. The crushed materials have an average particle size and a low over-crushing rate, simplifying the coal preparation process. Reduced investment and production costs.

It is one of the most popular crushing equipment in mining, sand and gravel aggregate, and mineral processing industries. The double-roll crusher uses the extrusion crushing principle to achieve precise particle size, low consumption, and wear resistance. It is an ideal equipment for fine crushing and particle shape optimization of medium-hard and brittle materials.

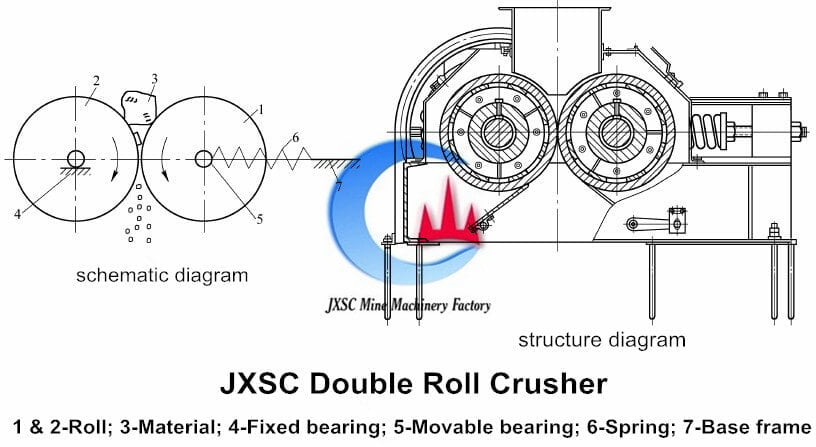

working principle & structure of Roller Crusher

Working principle

When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between it and the roller. As the rollers continue to rotate, the material is brought into the crushing cavity formed by the two rollers In the process, the material is crushed by being pressed, and then discharged from the lower part of the crushing roller. The width of the discharge opening of the crusher is determined by the minimum gap between the two rollers, and the width of the discharge opening determines the maximum particle size of the crushed product.

Structural features

- Roller shell: The surface can be designed as smooth (for handling brittle materials), toothed (for crushing sticky materials) or grooved (for improving material gripping ability).

- Adjustable roller spacing: The gap between the rollers can be adjusted to control the particle size of the output material.

- Frame: A rigid frame is used to increase stability and reduce vibration and noise during operation.

- Overload protection mechanism: When hard objects enter, springs or hydraulic devices trigger the rollers to retreat to avoid equipment damage.

why choose JXSC roller crusher

Features & advantages

1. Uniform and controllable particle size: precise control of the discharge size by adjusting the roller spacing (manual or hydraulic)

2. Strong wear resistance: The roller surface can be welded with a wear-resistant layer or the tooth plate can be replaced, which has a long service life (especially suitable for crushing high-hardness materials).

3. Energy saving and environmental protection: the unit energy consumption is lower than that of impact crusher, with less noise and dust.

4. Efficient sand making: suitable for machine-made sand production, the finished product particles are fine and uniform.

5. Low powder rate crushing: The special design of the roller surface can reduce over-crushing, which is suitable for industries such as coal and chemical industry that need to control the amount of powder.

models & specifications

Rotor size | Feed size(mm) | Discharge opening range(mm) | Capacity | Motor Power | Overall dimension(mm) |

φ400*250 | <25 | 1-20 | 1.5-10 | 5.5*2 | 3080*1260*780 |

φ600*400 | <35 | 1-20 | 5-20 | 15*2 | 3650*1540*960 |

φ800*600 | <40 | 2-30 | 15-30 | 22*2 | 4250*2000*1200 |

φ800*700 | <40 | 2-30 | 20-40 | 30*2 | 4250*2100*1250 |

φ1000*800 | <50 | 2-40 | 35-70 | 45*2 | 4900*3250*1310 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.