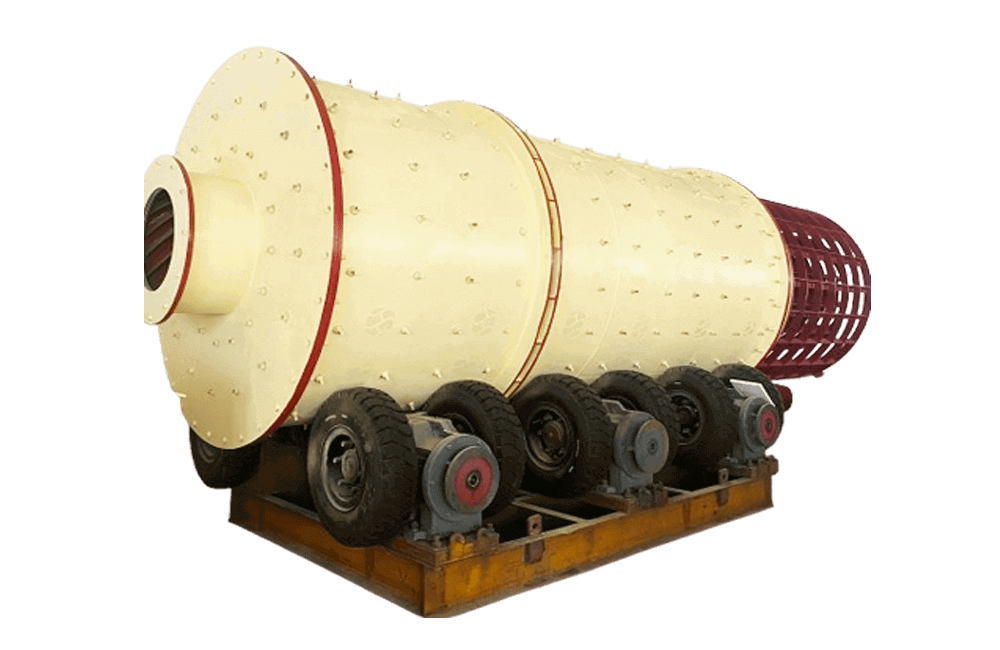

Rotary Scrubber

Capacity: 1-400 TPH

Feeding size: <100mm

Application: Rotary scrubber (trommel scrubber, drum scrubber) is widely used to wash and screen rock, ore, sand, gravel, and aggregates. Such as gold, diamond, copper, manganese, tantalum-niobium, tin, lead-zinc, zircon sand, chrome, iron ore, kaolin, coltan, quartz, chromite, barite, fluorite, bauxite, hematite, magnetite, or other minerals with high mud content and high viscosity processing.

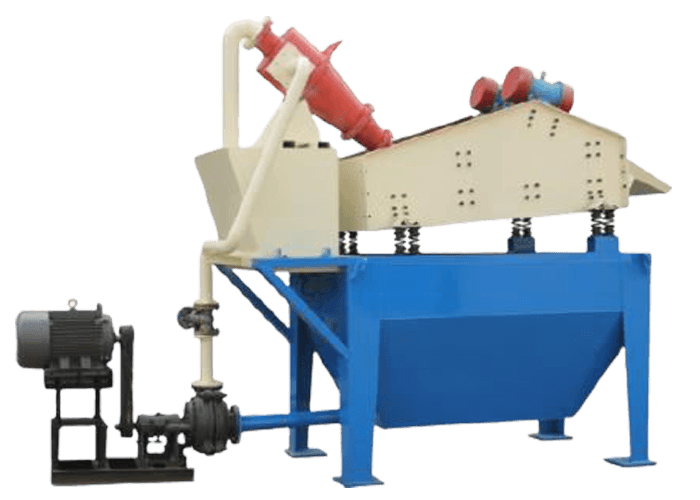

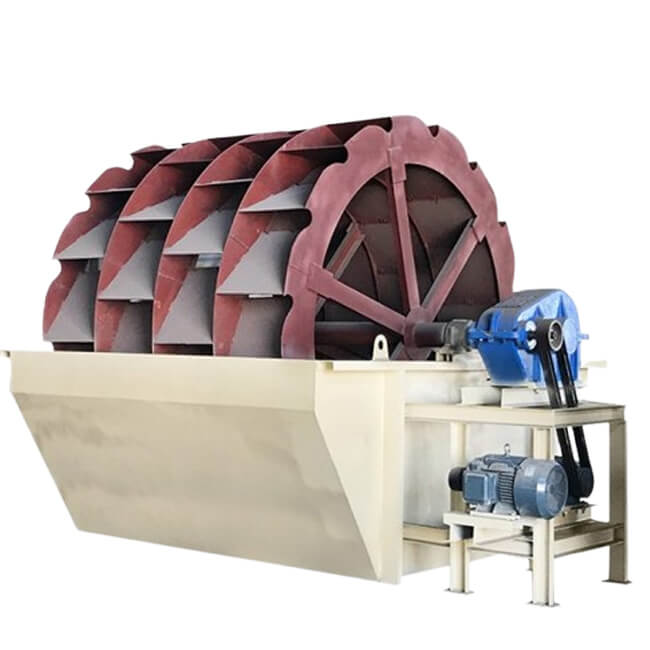

Products display

Introduction of rotary scrubber

The rotary scrubber is also called trommel scrubber, or drum washer, rotary drum scrubber; it can effectively wash and screen ore with high mud content/ solid and get cleaner products. Its main purpose is to strip away impurities such as dirt, dust, salt, etc., on the surface of the mineral to improve the subsequent mineral processing efficiency. The trommel scrubbers are mainly applied for washing gold, diamond, manganese, copper, tantalum-niobium-tin, iron ore, silica sand, fluorite, quartz sand, feldspar, kaolin, and other ores containing a lot of slime impurities.

In mineral processing, rotary scrubber is the most popular ore washing equipment, which plays a core role in cleaning, purification, classification, screening, and pre-enrichment. It has the features of strong adaptability, low energy consumption, and multi-functional integration, and is key equipment to reduce the processing volume of subsequent crushing, grinding, and other processes. It is often called gold wash trommel or diamond wash trommel.

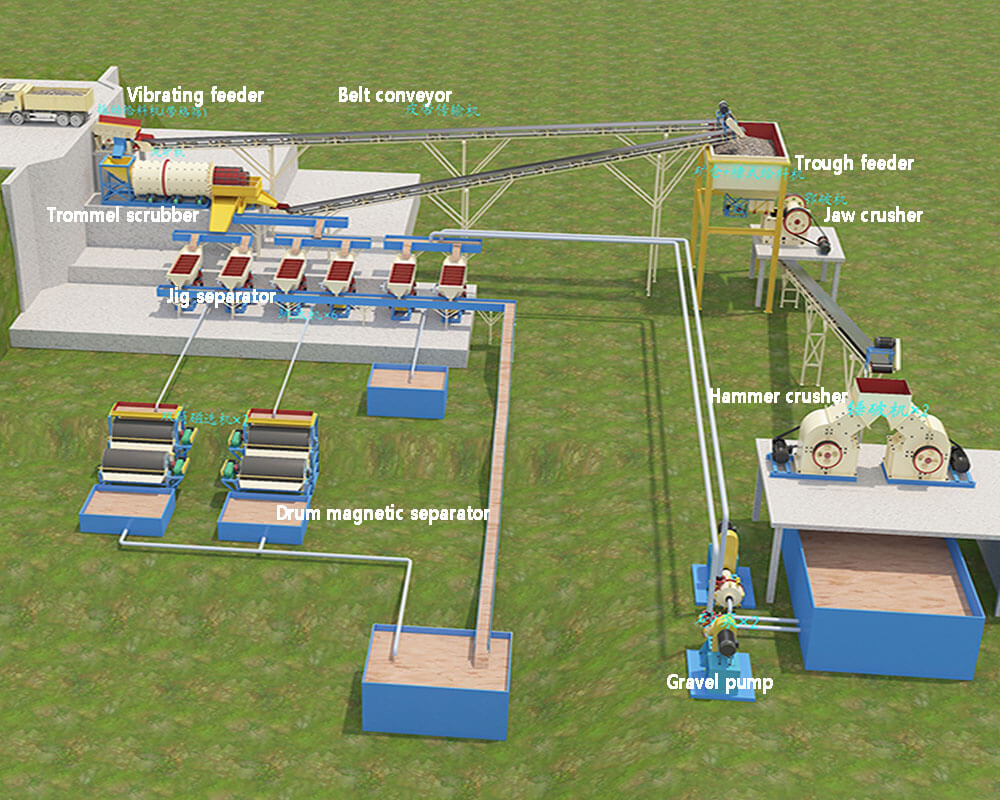

The trommel scrubber is usually equipped with sluice boxes or jigs to form a one-stop trommel washing plant or mobile jig plant. It is an ideal washing processing solution for alluvial gold and diamond mines with high clay content.

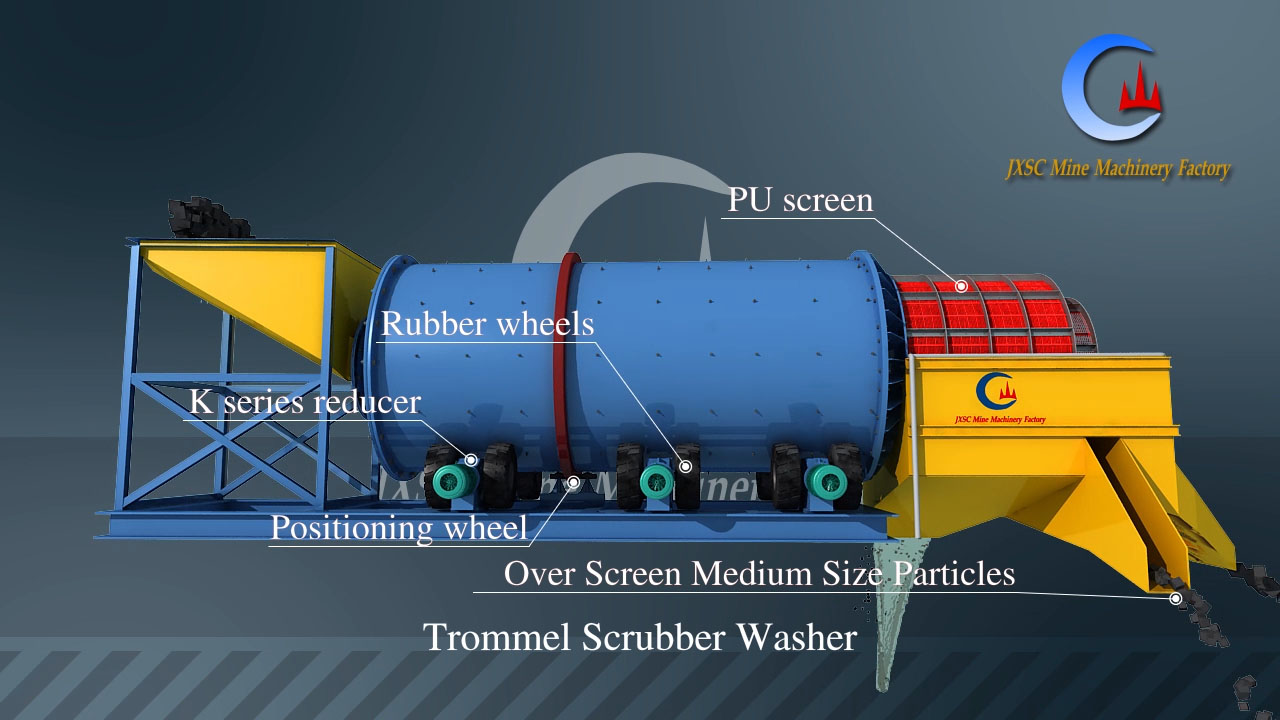

principle & structure of rotary scrubber

working principle

Our JXSC’s rotary scrubbers have two main parts: the drum scrubber and the screen. The drum part is used for washing ore, and then the screen inside is for sieving different-sized particles after ore washing processing. Those parts work together to remove water-soluble clays, deleterious materials, and coatings ,providing the final cleaner products.

The working principle of the trommel scrubber is to mix the ore to be washed and the cleaning medium inside the drum through a rotating drum. The friction and impact force generated by the rotation of the drum causes the dirt and impurities on the surface of the ore to fall off. During the cleaning process, the scouring and rolling action of the cleaning medium can further separate the impurities and dirt to the drain. In addition, the washed water flow takes away the separated impurities, achieving the cleaning and grading of the ore.

Structural features

1. Highly customized Material:

- The length & diameter of drum, inside drum lined material, screen mesh, layer quantity of screen, and screen material can be customized.

- Mobile type or stationary type; Diesel generator or electric motor.

2. The screens of our rotary scrubbers: The screen mesh size& layer qty & screen materials can be customized. Screen material has below choices:

①PU: wear resistant, long lifetime, fixed with screw, easy to replace.

②Manganese Steel: normal material, not easy to replace, short life time.

③Stainless Steel: Good quality, wear resistant.

3. Inner lined plates of trommel scrubber: Inside rotary drum scrubber can be Lined with a plate for washing more clean sticky material below choice.

① Rubber-lined Plates: wear-resistant, long lifetime, fixed with the screw, easy to replace.

② Iron plates welded inside drum: normal quality, welded. So the plates are not replaceable.

4. Well-known brand drive system and motor

- The driving system rubber pneumatic tire is high quality, wear-resistant, high temperature resistant, high tolerance, and a famous brand.

- Motor is high quality, chinese famous brand, can be speed-adjustable motor with frequency conversion electric cabinet. Huali & Simens motor and K-series Reducer.

Why choose JXSC rotary scrubber

Features & advantages of trommel scrubber

1. Efficient cleaning: The drum continuously rotates to achieve the triple effects of “rubbing-collision-washing” of the material, and has a significant cleaning effect on ores containing sticky mud impurities, with a cleanliness of more than 95%.

2. Strong adaptability: It can handle materials with a particle size of 0-300mm, especially for ores with high viscosity and high mud content, and is not easy to clog.

3. Low energy consumption design: The inclined design is adopted to achieve gravity feeding, and the energy consumption is reduced by 20%-30% compared with the trough type ore washer.

Durable structure: The drum wall is made of wear-resistant manganese steel, the key components can be replaced, and the service life is up to 5-8 years.

4. Easy operation: It supports remote monitoring and automatic adjustment, variable frequency speed control, and can adjust the speed according to the characteristics of the material.

5. Multi-function: JXSC trommel scrubber can simultaneously complete the washing, grading, desludging, removal of impurities, purification, and other processes to simplify the production process.

6. Easy to integrate: It can be easily used with other mineral processing equipment (such as crushers, screening machines, gold chute, etc.) to form an effective production process.

7. Low maintenance cost: Modular design, stable structure, easy replacement of wearing parts.

8. Environmental protection and water saving: Adopts integrated frame and elastic support structure, low noise; equipped with water circulation system, the recycling rate of washing water can reach more than 80%.

9. Configurable: Often combined with a sluice box to form a one-stop gold processing plant, improving the quality of the ore and reducing pollutants in the subsequent beneficiation process.

models & specifications

Model | Drum Dia(mm) | Drum&Screen Length (M) | Screen Mesh Size(mm) | Rotation Speed(r/min) | Feeding Size(mm) | Angle of Inclination(o) | Process Capacity(t/h) | Motor Power(kw) |

JXSC-400 | 400 | 2m+1.2m | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

JXSC-600 | 600 | 2m+1.2m | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 4 |

JXSC-750 | 750 | 2.5m+1.5m | ≤25 | 27.6 | ≤100 | ≤10 | 10-20 | 5 |

JXSC-900 | 900 | 3m+1.8m | ≤25 | 27.6 | ≤100 | ≤10 | 20-40 | 11 |

JXSC-1200 | 1200 | 4m+2m | ≤25 | 17 | ≤100 | ≤10 | 40-70 | 15 |

JXSC-1500 | 1500 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 70-100 | 30 |

JXSC-1800 | 1800 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 100-150 | 18.5*2 |

JXSC-2100 | 2100 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 150-200 | 22*2 |

JXSC-2400 | 2400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 200-250 | 22*4 |

JXSC-2700 | 2700 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 250-270 | 55*2 |

JXSC-3000 | 3000 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 270-300 | 30*4 |

JXSC-3200 | 3200 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 300-340 | 37*4 |

JXSC-3400 | 3400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 340-370 | 45*4 |

JXSC-3600 | 3600 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 370-400 | 55*4 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.