Mineral Jig Separator

Capacity: 1-25t/h

Feeding size: <10-25mm

Application: The mineral jig separator is widely used in gravity separation process of gold, diamond, coltan, lead-zinc, copper, tin, tungsten, titanium, manganese, tungsten ore, fluorspar ore, iron ore, chrome ore, barite, and other metal heavy mineral separation, non-metallic mineral purification.

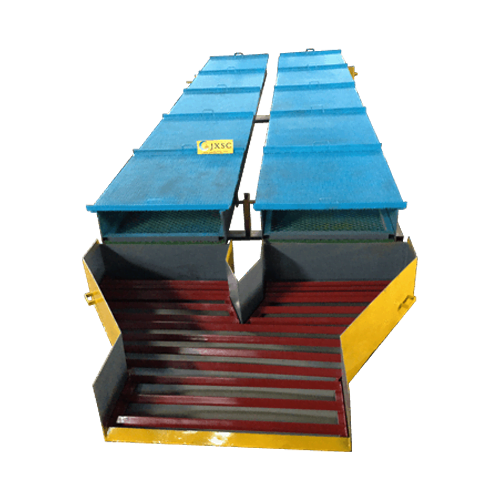

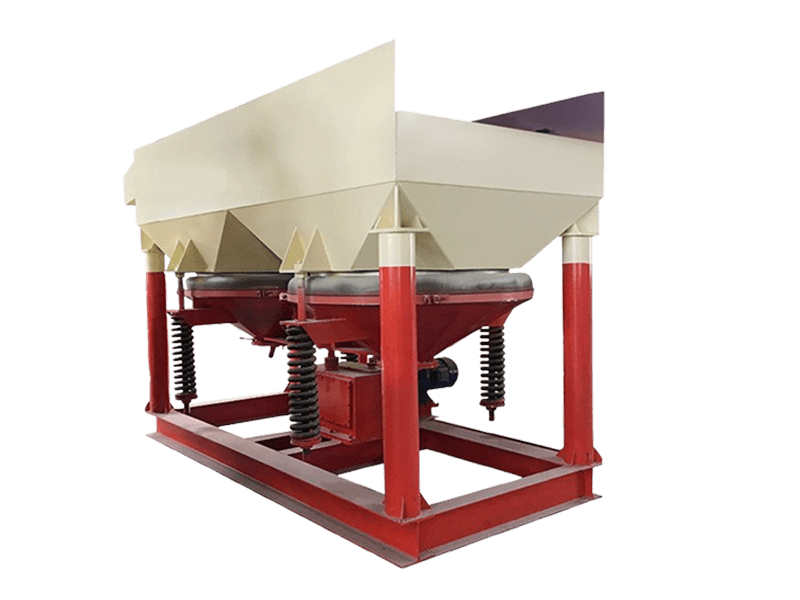

Products display

Introduction of jig separator

Jig separator (jig concentrator, jig machine, mineral jig, mining jig) is a mining gravity separation equipment that drives pulses of water upwards through a thick bed of settled sediment to keep it loose and agitated. This achieves gravitational separation by allowing the denser minerals to sink easily and quickly through the lighter minerals. Jig separators are widely used in the gravity concentration stage of various heavy metal, metallic, and non-metallic mineral separation plants. It is especially suitable for sorting metal ores, such as tungsten- and gold-containing placers, iron ore, tin ore, etc. It can handle a wide range of particle sizes and has good results from fine to coarse particle size sorting.

The mineral jig separator has the characteristics of high sorting efficiency, large processing capacity, environmental protection, and energy saving. It is the most common gravity separation machine in gold, manganese, tantalum-niobium, tin, iron ore, tungsten, and diamond processing solutions. JXSC supports customized mobile jig plants with trommel scrubbers or drum screens.

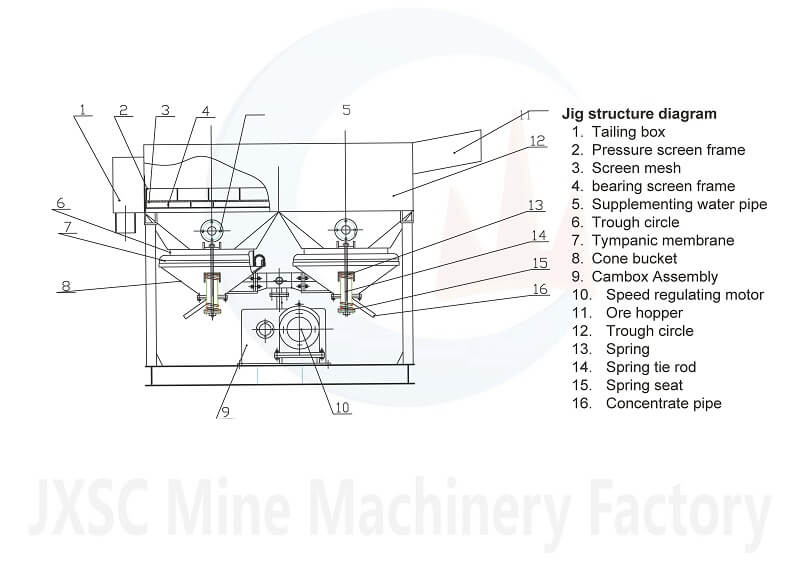

working principle of jig separator

The selected ore is continuously fed to the sieve plate of the jig chamber to form a thick material layer. The rising water flow is periodically blown through the sieve plate, causing the bed to rise and loosen, and then the water flow descends (or stops rising).

During this process, heavy minerals enter the lower layer and light minerals transfer to the upper layer. It is difficult for materials with low density to enter the lower space through the material layer with high density. Heavy minerals enter the concentrate tank through the screen, and light minerals enter the tailings tank for discharge.

Why Choose JXSC jig separator

features of Advantages of jig separator

1. Flexible customization: It can be connected with a trommel screen, rotary scrubber, gold sluice box and other equipment to form a small-scale mobile jig plant, used in gold and diamond washing processing plants.

2. High recovery rate: Recover 0.5% to 30% concentrate, increasing the recovery rate.

3. Highly adaptable: The stroke can be adjusted to suit different mineral processing

4. Efficient sorting capability: High sorting accuracy, wide processing particle size range, single equipment recovery rate can reach 80%~95%. It has an excellent effect on the beneficiation of various metal and non-metallic minerals.

5. Energy saving and low cost: No chemical additives, environmentally friendly gravity separation equipment. It occupies a small area and is simple and convenient to operate.

models & specifications

| Model | jigging chamber | diaphragm | Feeding size(MM) | Back Wash Water (M3/H) | Back Wash Water Pressure(Mpa) | Process Capacity (T/H) | Motor power (KW) | Dimension (MM) | Weight (Ton) | ||

| Shape | Area | Stroke | Jig frequency | ||||||||

| JT0.57-1 | Trapezoid | 0.57 | 10-17 | 80-120 | <10 | 18-20 | ≥0.1 | 1-3 | 1.5 | 1550x780x1530 | 0.6 |

| JT1-1 | Trapezoid | 1.1 | 10-17 | <10 | 20-30 | 2-4 | 2.2 | 2270x1110x1890 | 0.9 | ||

| JT2-2 | Trapezoid | 2.3 | 10-17 | 60-100 | <25 | 40-50 | 4-8 | 3 | 2900x1550x2000 | 1.4 | |

| JT4-2 | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 7.5 | 3900x2000x2460 | 3.2 | ||

| JT4-2A | Trapezoid | 4.5 | 20-30 | <25 | 80-100 | 10-15 | 4*2pc | 3900x2000x2460 | 4 | ||

| JT5-2 | Trapezoid | 5 | 20-30 | <25 | 80-100 | 10-20 | 7.5 | 4000x2050x2660 | 3.2 | ||

| JT6-3 | Trapezoid | 6.8 | 20-30 | <25 | 120-150 | 20-25 | 7.5+4 | 5400x2000x2460 | 5 | ||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.