Quartz Beneficiation

Quartz sand is also called silica sand (quartz sand has a SiO2 content of more than 98.5%, and silica sand has a SiO2 content of less than 98.5%). After mineral processing and purification, it can be made into high-purity quartz sand.

Quartz sand beneficiation plant is common includes washing, gravity & magnetic separation; a separation process to remove small or trace impurities in quartz and obtain refined quartz sand or high-purity quartz.

Quartz beneficiation Process

There are many types of silica resources and large storage capacity. quartzite, quartz sandstone and vein quartz are the main raw materials for producing high-purity sand. Quartz sand beneficiation aims to extract useful minerals in quartz sand and remove impurities to meet the requirements of different industrial uses.

1. Quartz gravity separation method is suitable for separating quartz ore associated with iron-bearing heavy minerals;

2. Quartz magnetic separation method is suitable for separating quartz ore associated with hematite, limonite, biotite and other impurities;

3. Quartz flotation separation method is suitable for separating quartz ore associated with feldspar ore.

4. Quartz electric separation: This method is more common in beneficiating fine-grained quartz sand.

5. Combined quartz beneficiation processes are usually used to achieve the best separation effect in the actual application.

- For the refined sand quartz for general industrial use, the simple process flow is selected as much as possible to reduce the purification cost. It is recommended to use the scrubbing-desliming-magnetic separation process.

- For high-purity and ultra-high-purity quartz used as high-tech, it is necessary further to purify the quartz by flotation, acid leaching and other combined process.

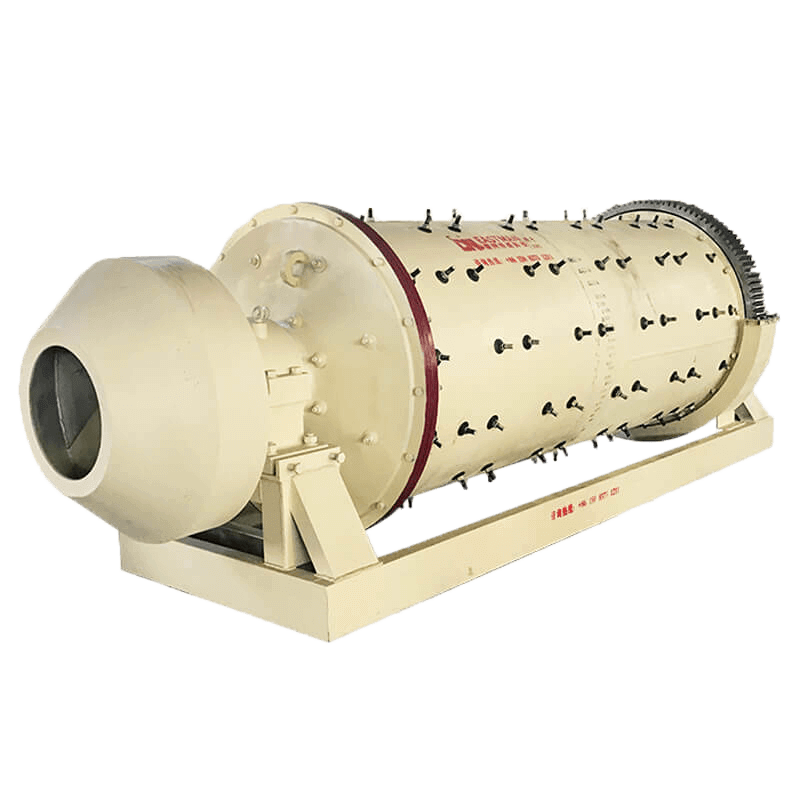

In practical applications, quartz mineral processing usually includes a combination of crushing, grinding, washing, gravity separation, magnetic or electrostatic separation and other processes. Contact us online to obtain the quartz processing plant equipment configuration and latest quotation!

Quartz Processing Plant

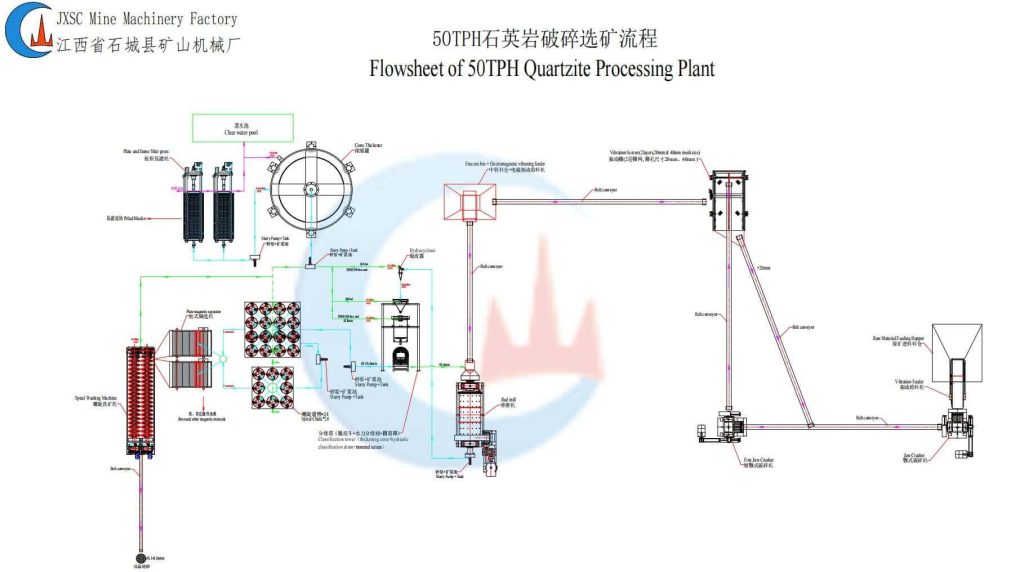

50TPH Quartzite Beneficiation plant

1. Washing-classifying-desilting: In the quartz sand beneficiation process, the fine-grained grade with a particle size of less than 0.1 mm is usually called slime. For quartz sand with a large amount of clay and ore mud, as the particle size becomes finer, the grade of silica gradually decreases, while impurities such as iron and aluminum rise instead. Using water washing-classifying-desilting method can effectively improve quartz grade.

2. Scrubbing: The effect of water-washing-grading desilting is poor for the thin film iron and adhesion impurities on the surface of quartz sand. This requires the removal of the thin film iron and adhesion impurities suitable for the sand surface by means of mechanical force and the abrasive force between the sand particles. After the grading desilting, a better impurity removal effect can be achieved.

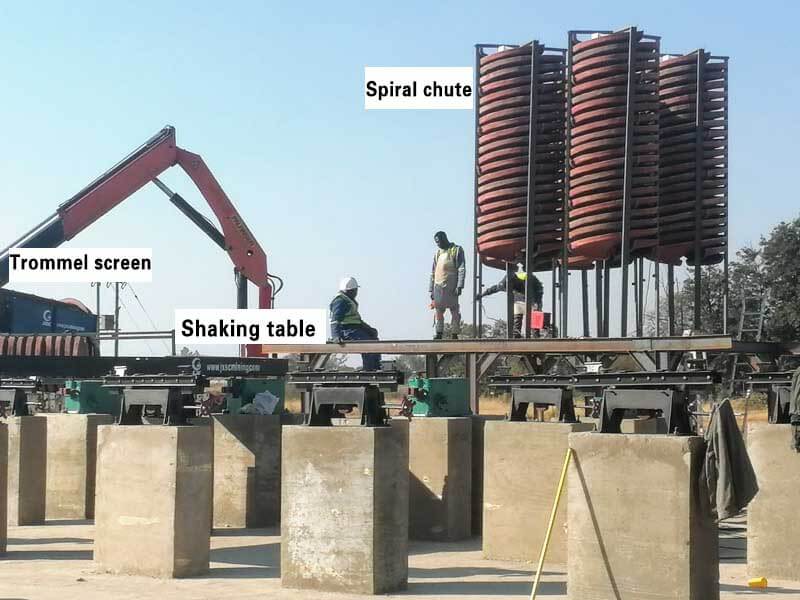

3. Gravity separation: It screens minerals according to their different gravity. Due to the difference in density, the mineral particles are affected by the fluid force and mechanical force in the medium, resulting in loose stratification, so that the ore particles are separated.

4. Magnetic separation: It separates the quartz sand’s magnetic impurity minerals and particles. A strong magnetic separator to separate the impurity iron in quartz is the key link. Magnetic separation can remove mechanical iron minerals (hematite, limonite, pyrite, ilmenite, biotite, etc.) mixed in quartz sand. It can also remove weak magnetic minerals and inclusions and disseminate impurities containing iron minerals.

5. Flotation: Flotation machine is the process of separating mineral particles by different physical and chemical properties on the surface of the mineral particles. The main function is to remove the related mineral mica and feldspar from the quartz sand.

6. Dewatering: The material is dehydrated and dried to obtain the required products, and the actual configuration should be adjusted according to the production needs.

The physical beneficiation method can only remove the impurities of mineral structure and rarely remove the impurities on the surface of quartz sand. The purer the quartz sand, the higher the use value, so it is necessary to further purify the quartz sand after flotation. Contact us to get quartz processing plant details and equipment factory price!

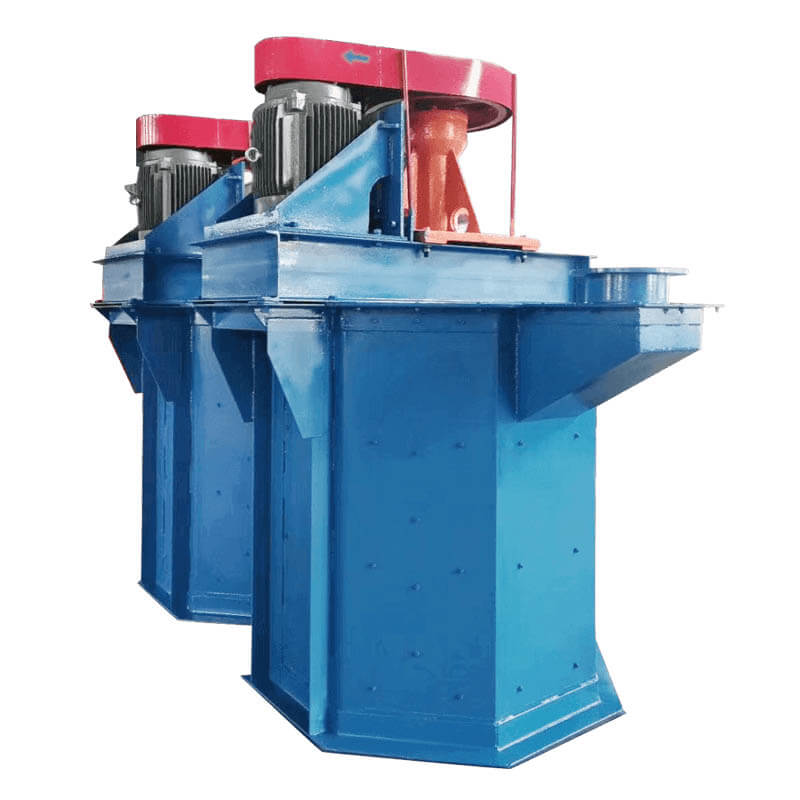

Related equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.