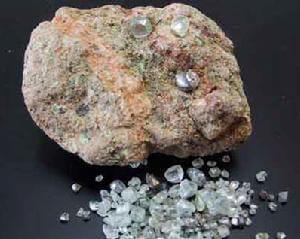

Diamonds were found in placer mines in India and Brazil, in river gravel in 1827, and in deposits in South Africa in 1866. The original rock containing diamonds, known as kimberlite, was found in Kimberley Town shortly after, and diamonds appeared on the scene soon after. Kimberlite is commonly known as the “porter” of diamond mines.

About Kimberlite Diamond

Kimberlite is an economically important rock type, so finding kimberlite leads to finding diamonds. Kimberlite is an igneous rock and is also the parent rock of diamond, so the search for diamond mines usually begins by looking for kimberlite. There are intermittent diamond deposits inside the kimberlite, and diamond is one of several minerals that exist. However, not all kimberlites contain diamonds, other stones often found with diamonds are mica, garnet and zircon. Diamond is the hardest substance known to human beings, and is often used as abrasives, cutters, etc. in industry. Diamonds with diamonds as primary stones have always been regarded by mankind as a symbol of power, majesty, status and wealth.

Diamonds ore are extremely rare, most diamonds were found in alluvial deposits. Loose diamonds are also found along existing and ancient shorelines, where they tend to accumulate because of their size and density. Kimberlite diamonds mines has poor weathering resistance, and is easily damaged by natural weathering after being exposed to the surface. Then, it is transported, sorted and deposited by flowing water to finally form alluvial diamond mine.

Alluvial diamond Processing

Alluvial diamond processing mainly includes the following two stages:

1. Preparation stage:

- crushing: jaw crusher

- screening: vibrating screen

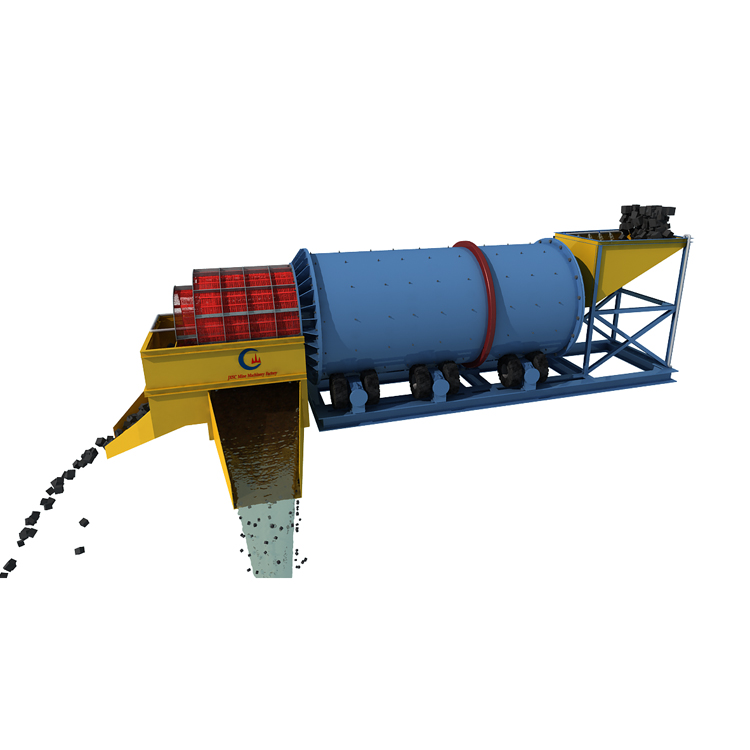

- washing: trommel scrubber

- grinding

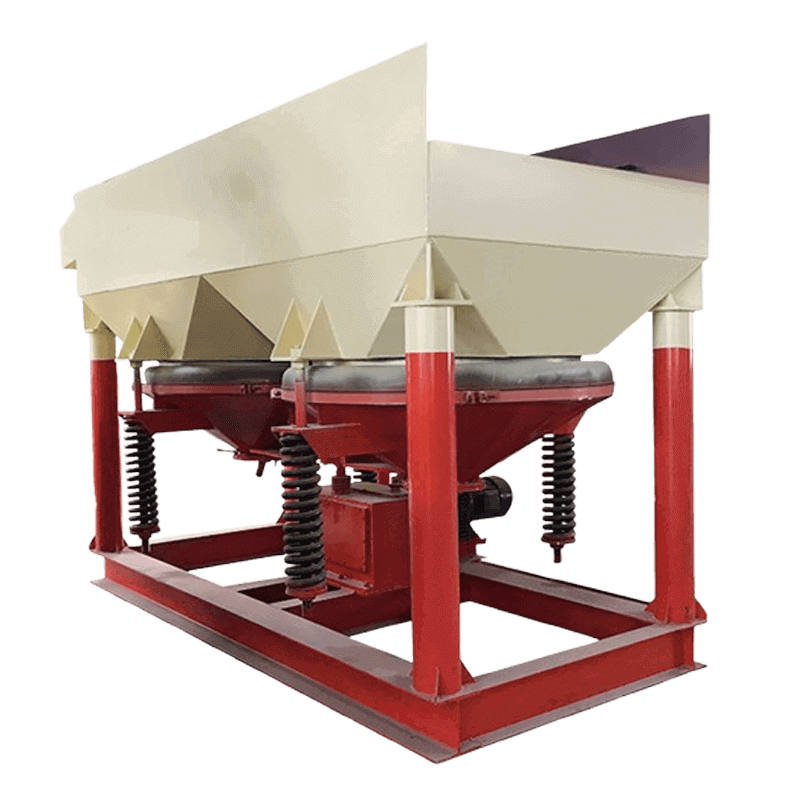

- classification: jig

2. The beneficiation stage: it is divided into two parts: roughing and selection.

- Rough separation: mainly plays the role of preliminary enrichment. The methods include jig beneficiation, heavy medium beneficiation and so on.

- Concentrate separation: The rough concentrate is further processed until diamonds are selected. The methods include X-ray beneficiation method, oil beneficiation method, etc.

Kimberlite Diamond Processing Plant

JXSC factory provided a full set 100tph kimberlite clay diamond washing plant for Brazil project. Below are more details about this project.

1. Raw ore information:

- Diamond ore contain much clay,

- The type of customer’s diamond mine: have 200 meters in radius and 20 meters deep of 240 million year old kimberlite which has been weathered to clay. It’s fine clay with very small particles that need to be. Disaggregated.

- Diamond particle size is 1-25mm

- Customer requires the processing capacity to be 100 tons per hour

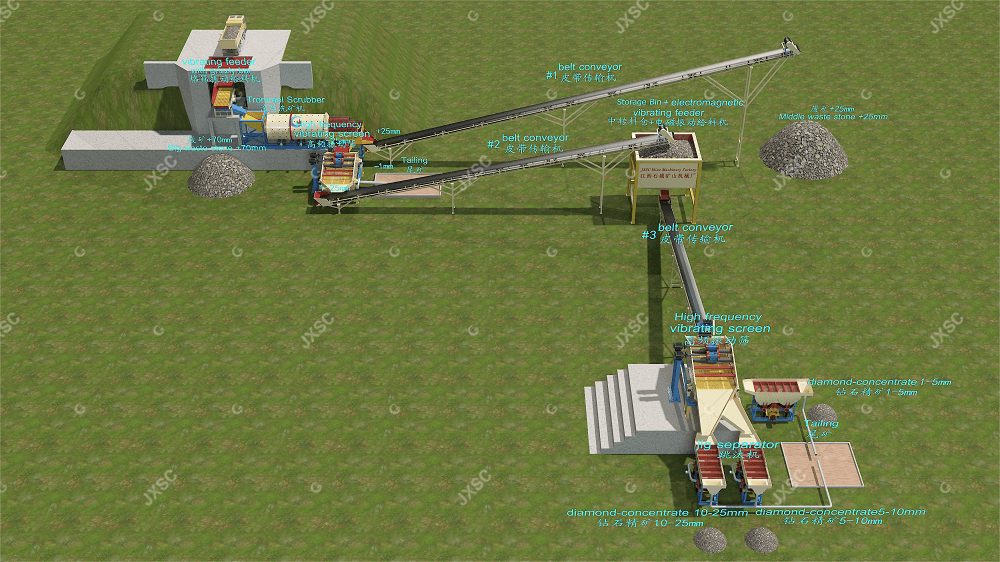

2. Flowchart explanation as follows:

- Dump truck or excavator send raw ore into raw material hopper, then to vibrating feeder

- Vibrating feeders evenly feed raw ore to trommel scrubber. The vibrating feeder has a grizzly bar,and the bar gap is 70mm, so over 70mm waste can be removed from this step.

- Trommel scrubber washing off clay from minerals, then sieving out over 25mm waste and less than 25mm ore.

- Over 25mm are sent to the waste stockpile by belt conveyor.

- Less than 25mm goes to the 1st high frequency vibrating screen. The sieve machine with 1mm mesh size, spray water on the ore when the screen is working, so it can further remove mud from minerals and remove 0-1mm mud water, 1-25mm go to fine ore bin by belt conveyor.

- Electromagnetic vibrating feeders evenly feed 1-25mm fine ore to 2nd high frequency vibrating screen via belt conveyor. The 2nd sieve machine with two layers screen, mesh size 5mm and 10mm. So it can sieve out 1-5mm, 5-10mm and 10-25mm three kinds sizes.The best beneficiation results can be achieved by sieving the 1-25mm material into three different sizes and feeding them into different jig machines.

- Get three product sizes from the 2nd high frequency vibrating screen. 1-5mm are fed into one jig, 5-10mm are fed into another jig, 10-25mm are fed into the 3rd jig. Finally you can concentrate all sizes of diamond concentrate from the three jigs.

3. Below is the 3D flowchart for this alluvial diamond washing plant:

This flowchart is a simple process but efficient and much more cost-effective compared with other complicated flowcharts.

Main Equipment for Diamond Processing plant

JXSC Mine Machinery Factory is a mining equipment manufacturer established in 1985, supplies an extensive range of quality mining machinery that is exported and used worldwide. We offer diamond mining solutions, mining equipment with competitive price, excellent service and free flow design.