Why has gold gravity separation become a preferred gold extraction process for both placer and hard rock deposits? In the global gold mining industry, gold gravity separation with its core advantages of low cost, low energy consumption, and high recovery rate, has become one of the mainstream processes for processing placer and hard rock deposits worldwide. For placer deposits, gold extraction processes can directly separate free gold particles using gravity separation equipment, without the need for complex chemical reagents. In hard rock deposits, beneficiation technology can effectively recover liberated coarse gold particles through gravity separation pretreatment, significantly reducing subsequent smelting costs. Whether processing coarse gold particles from alluvial/placer deposits or sputtered gold from liberated hard rock ores, gold gravity separation can achieve efficient recovery through flexible process configurations.

Gravity separation is the most economical and environmentally friendly extraction process in the gold mining. Placer gold deposits processing typically use equipment such as sluices and centrifugal concentrators, making it easy to recover gold particles. While processing hard rock deposits require jigs, shaking tables, and crushing and grinding processes combined with flotation, CIP, or CIL to improve the recovery rate to 95%+.

Characteristics & Challenges of Placer and Hard Rock Deposits

Characteristics of Placer Gold Deposits

Placer gold deposits (alluvial gold deposits) are secondary deposits formed by the long-term weathering and erosion of primary veins, resulting in the deposition of gold grains transported by water. They mainly exist in the form of free native gold and are typically distributed in riverbeds, ancient river channels, or alluvial plains. The gold grains have smooth surfaces and diverse morphologies (flaky, granular, dendritic), with a grain size mostly concentrated between 0.1-2 mm. These highly liberated gold grains do not require complex crushing and grinding; they can be directly separated through simple screening and washing, followed by gravity separation. Typical placer gold grains have a purity of over 90%, with impurities mainly consisting of light minerals such as quartz and feldspar, further reducing the difficulty of separation.

Challenges Of Placer Gold Separation:

Gold particles have already naturally liberated, making the recovery process relatively simple, typically requiring only screening, washing, and gravity separation (such as sluices or centrifuges). Placer ore generally has a low density, with impurities consisting of light minerals such as quartz and feldspar, resulting in a significant density difference with gold, creating a natural advantage for gravity separation.

However, the challenge lies in the fact that fine-grained gold (<0.1mm) is easily lost with water flow, and high clay content can interfere with the separation process, affecting the recovery rate. Therefore, pretreatment (such as desliming) and efficient washing equipment are crucial. In actual production, efficient stratification can be achieved by adjusting the water flow rate (e.g., a spiral sluice with an inclination angle of 12-15°) and the medium density.

Characteristics of Gold Grains in Hard Rock Deposits

Gold grains in hard rock deposits often exist as sulfide mineral inclusions or lattice-embedded structures. Common carrier minerals include pyrite, galena, and arsenopyrite. The gold grains are extremely fine, some appearing as microscopic or submicroscopic gold, requiring staged grinding and classification processes to achieve individual grain liberation. Hard rock ores have a significantly higher density than placer deposits. Due to the large amount of sulfide minerals present, the density difference between gold and the sulfide minerals is reduced, increasing the difficulty of sorting.

Challenges Of Hard Rock Gold Separation:

The main challenges of gravity separation in hard rock are insufficient liberation and gangue inclusions. Over-grinding leads to gold grain mudification, while under-grinding leaves gold encapsulated. Simultaneously, a large amount of sulfide minerals (such as pyrite) with densities close to gold in hard rock slurries easily enter the gravity concentrate, forming a “high-impurity concentrate.” These ores are commonly found in underground veins or open-pit mines, where gold grains are microscopically encapsulated or associated with sulfides, making direct gravity separation impossible.

Crushing to a suitable particle size is essential to improve gold liberation; otherwise, it will affect the recovery efficiency of subsequent shaking tables or jigs. Furthermore, sulfide ores may cause excessive gold encapsulation, requiring additional cyanidation or flotation for recovery. Gravity separation can be used to recover coarse gold grains, flotation can treat gold encapsulated in fine sulfide grains, or CIP or CIL processes can be used to maximize ore grade.

Gravity Separation Solutions for Placer Gold

Equipment for Placer Gold

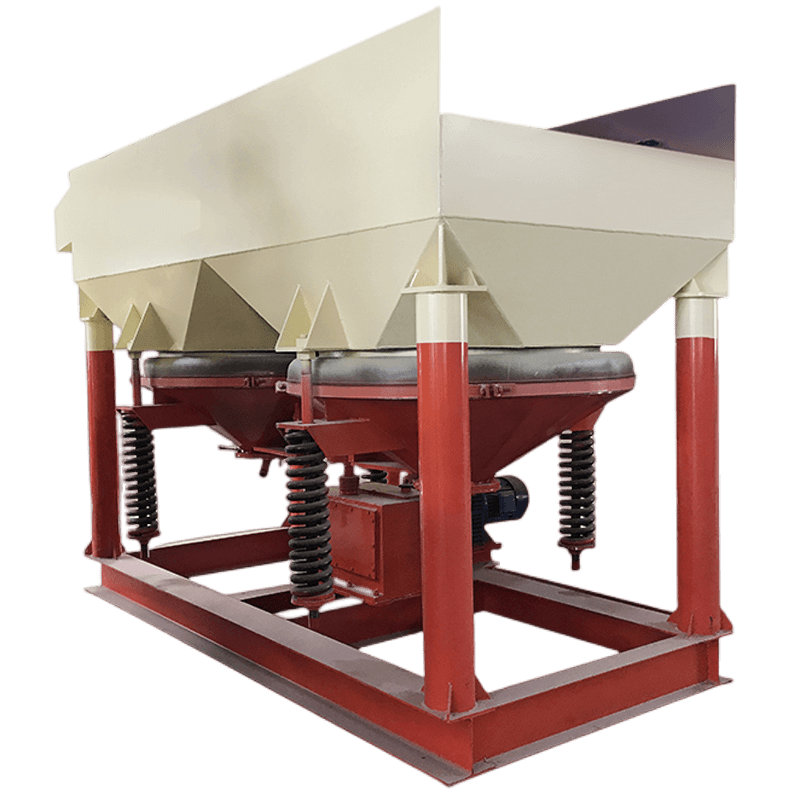

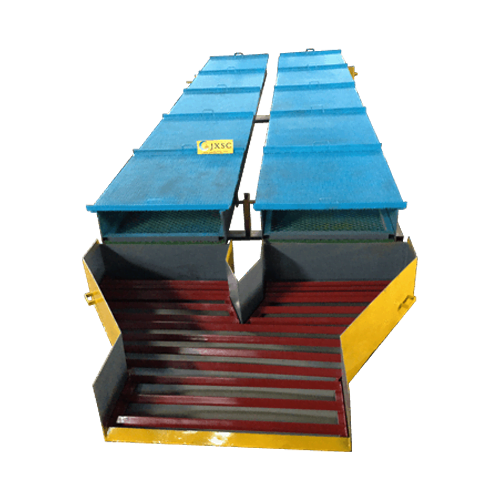

The recovery of alluvial gold primarily relies on physical separation. Centrifugal concentrators are particularly suitable for the efficient enrichment of fine-grained gold (<0.5mm), utilizing the centrifugal force generated by high-speed rotation to enhance gravity separation, especially suitable for alluvial gold deposits with a high proportion of fine-grained gold. Spiral chutes, with their advantages of non-powered operation (relying solely on gravity and centrifugal force) and low cost, have become the preferred equipment for fine-grained gold separation. Jigs achieve mineral stratification through vertical alternating water flow, with their core advantages being high throughput (1-25t/h per unit) and a gold recovery rate of over 90% for coarse-grained gold. Shaking tables are the “gold purification weapon” in the fine-grained stage of placer gold beneficiation, achieving precise separation of gold particles and gangue through the synergistic effect of reciprocating motion of the table surface and transverse water flow, resulting in a high enrichment ratio. Gold sluices are the most traditional equipment, suitable for the recovery of coarse-grained gold, simple to operate and low in cost, but require regular cleaning of the enriched gold concentrate. In addition, although the gold pan is inefficient, it remains widely used in small-scale exploration and sample inspection.

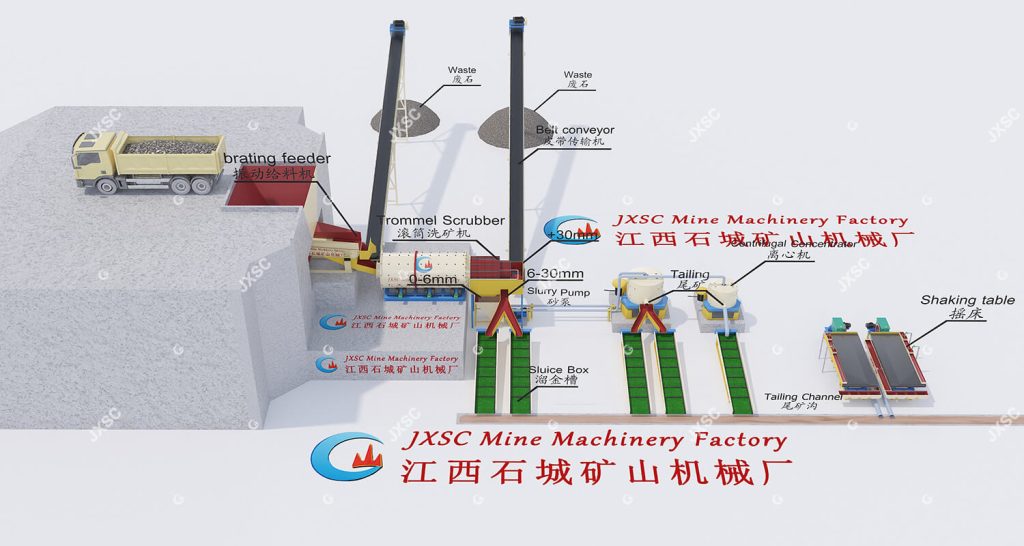

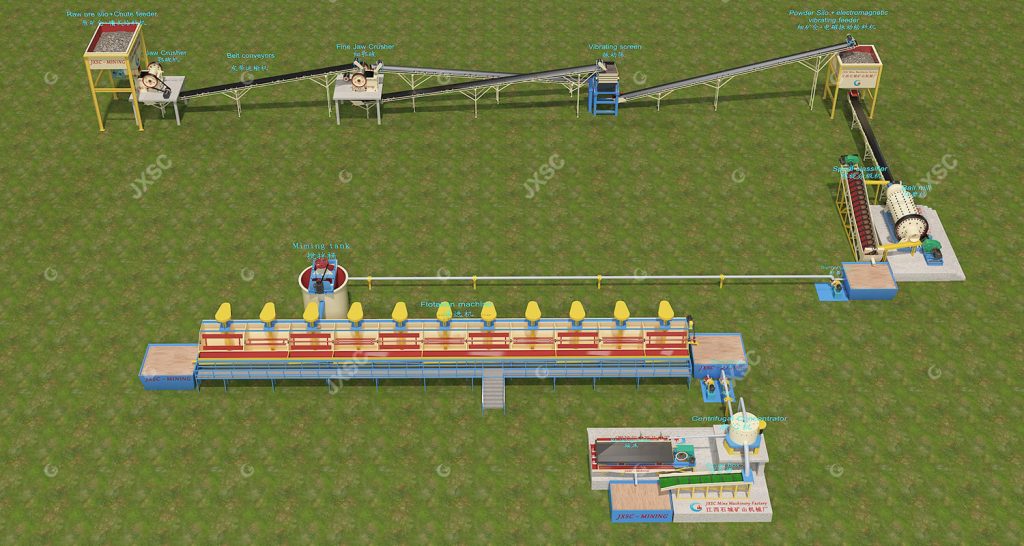

Standardized Flow for Placer Gold

1. Pretreatment: Washing and screening primarily remove gravel, clay, and fine mud impurities from the ore surface to prevent clogging of the gravity separation equipment or a decrease in separation efficiency. First, the muddy ore sand is washed to reduce interference from adhesion on gold particle attachment. Then, screening removes large pieces of waste rock, making the ore sand particle size uniform and improving separation efficiency. The trommel scrubber/drum screen achieves desliming through friction and collision between the ore and the drum wall, with a stable desliming rate of 90%+.

2. Gravity Concentration: Utilizing the high density of gold, gold sand is collected centrally using centrifuges and shaking tables. The shaking table first processes the coarse particles, producing a medium concentrate with a grade of 30-50 g/t by adjusting the transverse slope and wash water. The fine particles enter the centrifugal concentrator, where the high-speed centrifugal force field overcomes the gravity settling limit of fine gold particles, recovering microscopic gold missed by traditional equipment.

gravity separation Solutions for hard rock

Equipment for Hard Rock Gold

The key to gravity gold extraction from hard rock ore lies in the thorough liberation of gold particles, which requires a more specialized combination of equipment. Jigs are the most commonly used roughing equipment, achieving efficient stratification of gold particles and gangue through pulsed water flow, particularly suitable for separating particles of 0.5-3mm. Shaking tables are responsible for the cleaning stage, using lateral water flow and table vibration to achieve precise separation, showing significant effectiveness in recovering fine gold particles. Spiral separators are suitable for processing coarser particles (0.1-2mm), especially for reprocessing tailings containing small amounts of gold.

When selecting equipment, special attention should be paid to the ore properties; ores with high sulfide content may require pre-oxidation treatment. In actual hard rock gold beneficiation, combining gravity separation equipment such as centrifugal concentrators and shaking tables can improve the overall gold recovery rate.

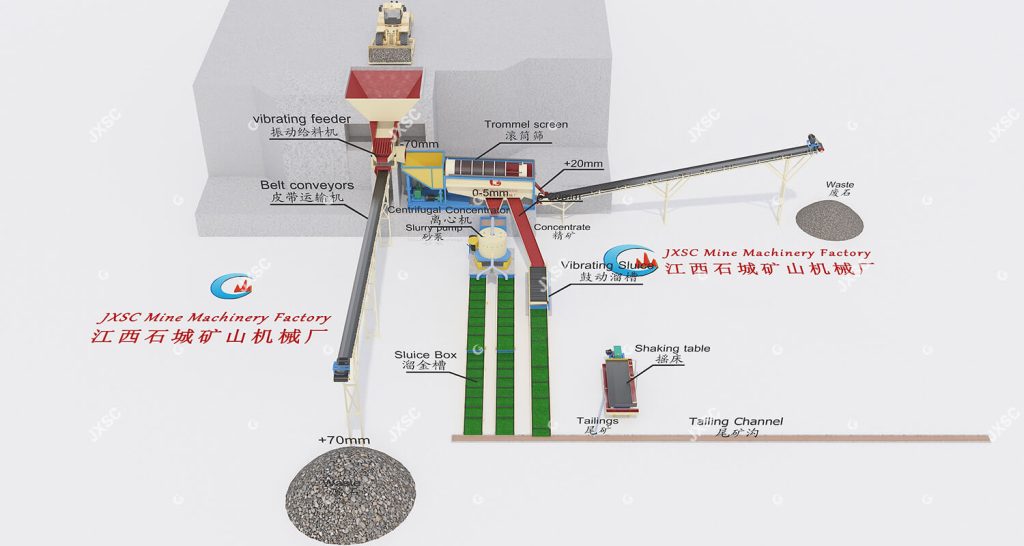

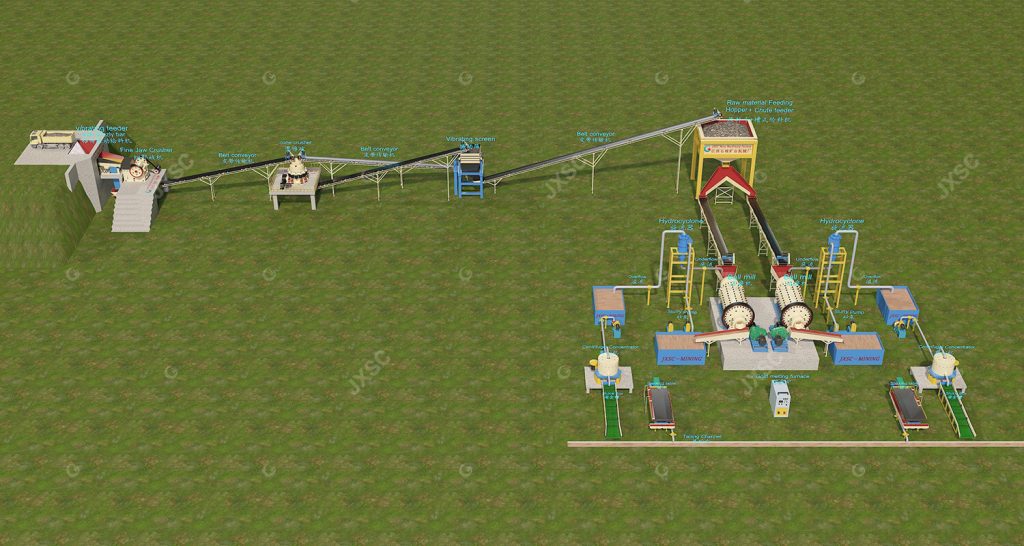

Hard Rock Gold Co-process Flow

1. Crushing Process: A three-stage closed-circuit crushing process is adopted: jaw crusher for coarse crushing, cone crusher for medium crushing, and high-efficiency impact crusher or hammer crusher for fine crushing. Special attention is paid to pre-screening, which can reduce over-crushing by 10-15%.

2. Grinding and Classification: The first stage uses an overflow ball mill, and the second stage uses a hydrocyclone group or spiral classifier. A closed-circuit ring mill device achieves the best liberation effect.

3. Single Gravity Separation:

The heavy media hydrocyclone achieves a tailings removal rate of 85% (removing low-density gangue), and the shaking table further refines the coarse concentrate. A PLC automatic control system links the crushing, grinding, and classification stages to achieve stable slurry flow rate and concentration (30-35%), with a coarse gold recovery rate of 88%. No reagents are required, resulting in low environmental costs. Single gravity separation is mainly suitable for processing quartz vein-type and altered rock-type deposits with a coarse gold content ≥50%.

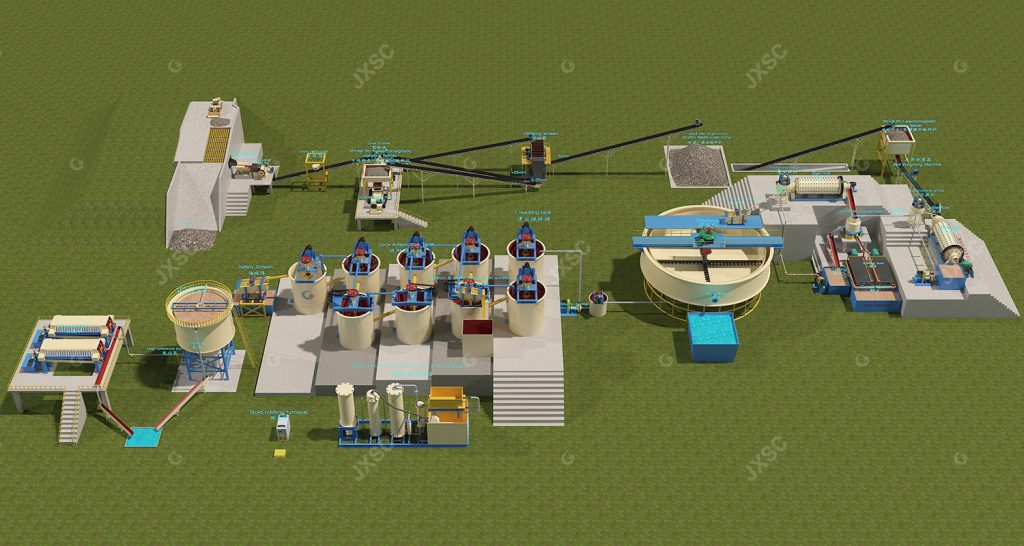

4. Gravity Concentration + Flotation

In hard rock gold deposits, gravity concentration alone is insufficient to recover gold encapsulated in fine-grained sulfide ore (accounting for 20-30%). A synergistic process combining gravity concentration for priority recovery of coarse-grained gold with flotation for recovery of fine-grained gold achieves complementary advantages. Gravity concentration recovers high-value coarse-grained gold in advance, reducing flotation reagent usage (by 30%). Flotation utilizes the natural floatability of sulfide ore to efficiently recover fine-grained gold, increasing the overall recovery rate to 95%. This is particularly suitable for processing hard rock deposits with high sulfide ore content.

5. Gold Gravity Concentration + CIP/CIL Process

Main flow: Gravity concentration for coarse-grained gold recovery (40% recovery rate) → Cyanide leaching of gravity concentration tailings (sodium cyanide concentration 0.05-0.08%) → Activated carbon adsorption (CIP process) → Electrolysis to obtain gold mud. When processing highly oxidized ores, gravity concentration tailings are concentrated before entering the leaching system. High-strength activated carbon is used (which can achieve a gold adsorption rate of 99%). The gravity separation combined with CIP or CIL process is mainly suitable for Carlin-type and micro-disseminated deposits with fine-grained gold and micro-gold content ≥50%.

Placer gold separation often utilizes washing, screening, shaking tables, and centrifugal concentrators to efficiently recover free native gold. Gravity gold concentration for hard rock gold deposits combines a scientific crushing-grinding-classification-gravity separation pretreatment process, and further utilizes flotation, CIP, or CIL during gravity concentration to enhance recovery rates. Whether it’s low-cost pretreatment for placer gold or synergistic gravity-flotation for hard rock, a customized solution must be developed based on the characteristics of the ore sample. JXSC provides complete process design, equipment selection, and technical support, turnkey solutions for placer/rock gold deposits. Contact us to help you achieve greater efficiency!