Did you know that approximately 80% of the world’s tungsten resources come from only two types of tungsten ore? The answer is: wolframite and scheelite. As a strategically vital metal for modern industry, tungsten, with its ultra-high melting point (3410°C) and extreme hardness, is an irreplaceable material in aerospace, electronics manufacturing, and defense industries. However, these two key tungsten ores, wolframite and scheelite, while both major sources of tungsten, have significantly different extraction technologies. This article will systematically compare the extraction methods for the two tungsten ores, analyze their mineral characteristics and core extraction steps, and help readers fully grasp the key technologies of tungsten ore processing.

There are two main types of tungsten ore extraction: wolframite, known for its high density and ease of separation, is brittle and its extraction relies on gravity separation combined with magnetic separation. Scheelite, on the other hand, has a lower density and is enriched using its unique fluorescence properties. Its density difference with gangue minerals is small, making flotation the mainstream technology.

What is wolframite and how is it extracted?

Characteristics of Wolframite:

Wollastonite is an important tungstate mineral whose physical and chemical properties are significantly influenced by the iron-manganese ratio. When the Fe content is high, the mineral is deep black and strongly magnetic. Varieties with higher Mn content are lighter in color and less magnetic.

Wolframite typically has a density between 7.1-7.5 g/cm³, much higher than common gangue minerals, making gravity separation the primary beneficiation method.

Such as in China, most wolframite deposits are associated with granite and often contain cassiterite, pyrite, and other minerals, increasing the difficulty of beneficiation. However, Myanmar’s alluvial tungsten ore has a high Fe content and strong magnetism, requiring a magnetic separation process for easy separation. Understanding the composition and distribution characteristics of wolframite helps optimize extraction processes and improve resource utilization.

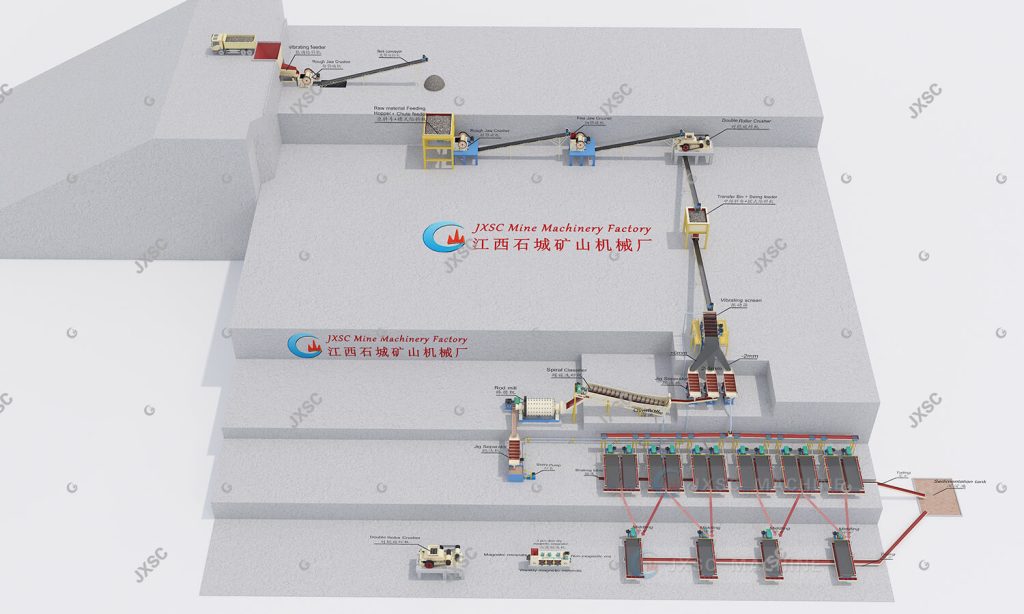

Wolframite Extraction Process

The standard wolframite extraction process primarily uses gravity separation as its core method, supplemented by magnetic/electrostatic separation for purification. Its process logic revolves around three steps: “liberation-enrichment-purification,” adapting to the coarse-grained, high-density mineralogical characteristics of wolframite.

1. Pretreatment: Washing, Crushing, and Grinding

First, the raw ore undergoes three-stage crushing equipment: jaw crusher → cone crusher → roller crusher. Jaw crushers (such as the PE600×900 type) are preferred for coarse crushing, suitable for the high compressive strength requirements of large ore blocks. Roller crushers are used for fine crushing to avoid over-grinding of brittle wolframite. The ore particle size is reduced to below 15mm. The grinding stage typically uses a closed-loop circulation of ball mill and spiral classifier to grind the ore to a suitable separation particle size of 0.3-2mm. To achieve the best separation effect, a drum screen or washing machine can be used to remove surface slime impurities. The main purpose of the pretreatment stage is to liberate wolframite from gangue minerals (such as quartz and feldspar), creating conditions for subsequent gravity separation and enrichment.

2. Gravity Separation and Enrichment

Gravity separation is the core step in the entire process. Depending on the ore characteristics, equipment such as jig separators (for coarse particles), shaking tables (for medium and fine particles), or spiral sluices (for fine particles) can be selected. Shaking tables (6-S type) use inclined water flow and vibration to move the wolframite laterally to the concentrate end. Further additions such as spiral chute sweeping can be made to increase the total recovery rate to 85%, maximizing resource utilization. Its main advantages are low cost, no reagent contamination, and suitability for processing coarse-grained tungsten minerals. However, it has poor adaptability to fine-disseminated ores.

3. Purification and Impurity Removal

The magnetic separation process primarily utilizes the weak magnetic properties of wolframite, employing a three-disc magnetic separator to separate associated magnetic impurities such as magnetite and ilmenite. Electrostatic separation uses a high-voltage electrostatic separator specifically to treat cassiterite, which has a similar density to wolframite. When the concentrate contains excessive levels of phosphorus and arsenic, chemical purification using alkaline leaching is necessary. The concentrate is mixed with sodium carbonate and roasted, followed by hot water leaching, with tungsten entering the solution as sodium tungstate. This method yields a final product with a WO₃ content ≥65%, meeting industrial application standards.

4. Tailings Treatment

Tailings from gravity separation are rich in heavy metals, and improper treatment can lead to environmental pollution. Modern concentrators generally employ dry tailings discharge, closed tailings dam management, and wastewater recycling systems to comply with increasingly stringent environmental regulations.

What is scheelite and how is it extracted?

Characteristics of Scheelite:

The most prominent characteristic of scheelite is its bright blue fluorescence under ultraviolet light, making it highly recognizable during exploration and beneficiation. It is widely used in the manufacture of cemented carbide, specialty steels, and fluorescent materials. High-quality scheelite can also be used to produce artificial gemstones and is a core raw material source for high-end tungsten products (such as cemented carbide).

Scheelite has a relatively low density (5.9-6.1 g/cm³), with little difference in density compared to gangue minerals such as quartz and calcite, and it is non-magnetic. Therefore, extracting tungsten ore from scheelite using flotation has become the mainstream extraction technique. This process is well-suited to process fine-grained tungsten ores, intergrowth characteristics of scheelite.

Scheelite Extraction Process

1. Scheelite Crushing and Grinding

The crushing process is the same as for wolframite, but the grinding requires finer grinding, mainly grinding equipment using overflow ball mills or rod mills. The grinding process typically employs a closed-loop system of “ball mill + spiral classifier,” and the grinding concentration is strictly controlled between 65-70%.

2. Desulfurization from Scheelite

Desulfurization is a crucial pretreatment step, using butyl xanthate as the collector, adjusting the pH to 9-10 with lime, and using XCF-type flotation machines. The process can consist of one roughing stage followed by two scavenging stages, effectively removing over 95% of sulfide minerals. This effectively avoids competition between sulfur minerals and scheelite for the collector during subsequent flotation, improving flotation efficiency by 12%.

3. Flotation Separation

The selection of flotation reagents is particularly critical. Commonly used are fatty acid collectors (such as sodium oleate) and sodium silicate as depressants, optimizing the pulp pH (9-10) to selectively float scheelite. To address complex calcareous gangue, a “lime-sodium carbonate” dual-alkali control system was developed, combined with water glass as a highly efficient depressant. Typically, a three-stage flotation process is used to remove sulfides and calcareous gangue impurities, yielding high-grade, high-quality scheelite concentrate. This flotation method achieves a recovery rate of 85-90%+ for processing fine-grained tungsten ore, but the reagent cost is higher than that of gravity separation.

4. Thickening and Dewatering

Finally, the flotation-processed scheelite concentrate is pumped to a thickener, where the slurry concentration is adjusted to meet the requirements of the disc vacuum filter. The underflow from the thickener is pumped to the disc vacuum filter for filtration and dewatering; the overflow from the thickener is clear water, which is returned to the return water tank.

Conclusion

VS | ||

Core Process | Gravity separation (jigging + shaking table) | Flotation (fatty acid/chelating agent) |

Applicable Particle Size | Coarse-grained mainly | Fine-grained mainly |

Recovery Rate | 70-80% (fine-grained); 90% (coarse-grained) | 85-90%+ (fine-grained) |

Cost | Medium (no reagents) | High (reagents + multi-processes) |

Environmental Friendliness | High (no chemical pollution) | Medium (needs reagent wastewater treatment) |

Both types of tungsten ore are core raw materials for high-end manufacturing processes such as cemented carbide. The extraction processes for wolframite and scheelite differ significantly due to their different mineral characteristics: the extraction of tungsten ore from wolframite primarily uses gravity separation, involving crushing, grinding, liberation, jigging/shaking table enrichment, and magnetic/chemical purification to efficiently recover coarse ore. Extraction of scheelite relies on flotation combined with chemical leaching, which can process low-grade fine-grained ore, but presents greater environmental challenges. Does your mine need a customized beneficiation solution? Contact us now to learn how to optimize your tungsten ore beneficiation equipment and improve resource utilization!