Mines in remote areas often face high logistics costs, lengthy infrastructure development cycles, and challenging terrain. In mining scenarios with limited infrastructure and complex topography, traditional fixed crushing plants not only require significant initial investment, but also incur substantial time and financial costs for equipment relocation and commissioning whenever the ore body changes or the mining site shifts. However, the emergence of mobile ore crushing technology is providing a groundbreaking solution to these challenges. This article will delve into the 4 major advantages of mobile crushing equipment, revealing how it brings greater flexibility and economic benefits to remote mines.

With its modular design and rapid deployment capabilities, the mobile ore crushing solution can directly crush ore in scenarios such as near mines, complex terrain, and harsh environments. This significantly reduces transportation distances, thereby substantially improving operational efficiency and lowering overall production costs.

Why are mobile crushing plants the preferred solution for remote mines?

Challenges of Stationary Crushing Plants in Remote Areas

Deploying stationary crushing plants in remote mining areas often requires significant upfront investment in road construction, site leveling, and the establishment of supporting facilities. The infrastructure development alone can take 3-6 months and account for more than 40% of the total project investment. In mountainous, desert, or jungle regions with poor transportation infrastructure, the difficulty of constructing a mining crushing plant increases exponentially.

The Impact of Ore Transportation Costs on Profitability

In traditional models, uncrushed raw ore needs to be transported over long distances by heavy-duty trucks to a central processing plant. This not only results in enormous fuel consumption, but also leads to continuously rising fleet maintenance and labor costs. For short-term mining projects or those with dispersed ore deposits, it is often impossible to recoup the investment costs of a fixed production line. However, mobile crushing solutions can operate directly near the mine site, pre-crushing the ore to smaller particle sizes, increasing the transport volume per trip by 3-5 times, thereby significantly reducing logistical pressure.

Modular mobile crushing plants can be quickly relocated as mining operations advance, and even reused across different mining areas. This “plug-and-play” feature is particularly suitable for small-scale trial mining during the exploration phase or the economic development of marginal-grade ore bodies, helping mining companies minimize investment risks.

4 core benefits of mobile ore crushing

Benefit 1: Significantly Reduced Transportation Costs

In traditional mining operations, transportation costs typically account for 30%-50% of total costs. These costs are primarily driven by three factors: firstly, the low density of raw ore leads to inefficient transportation, with the transportation cost per ton of raw ore being 2-3 times higher than that of finished aggregate. Secondly, poor road conditions in remote areas result in significantly higher fuel consumption and maintenance costs for vehicles compared to flat areas. Finally, long-distance transportation increases labor and management costs, including driver salaries and logistics scheduling. These combined factors make transportation costs one of the main factors squeezing mining profits.

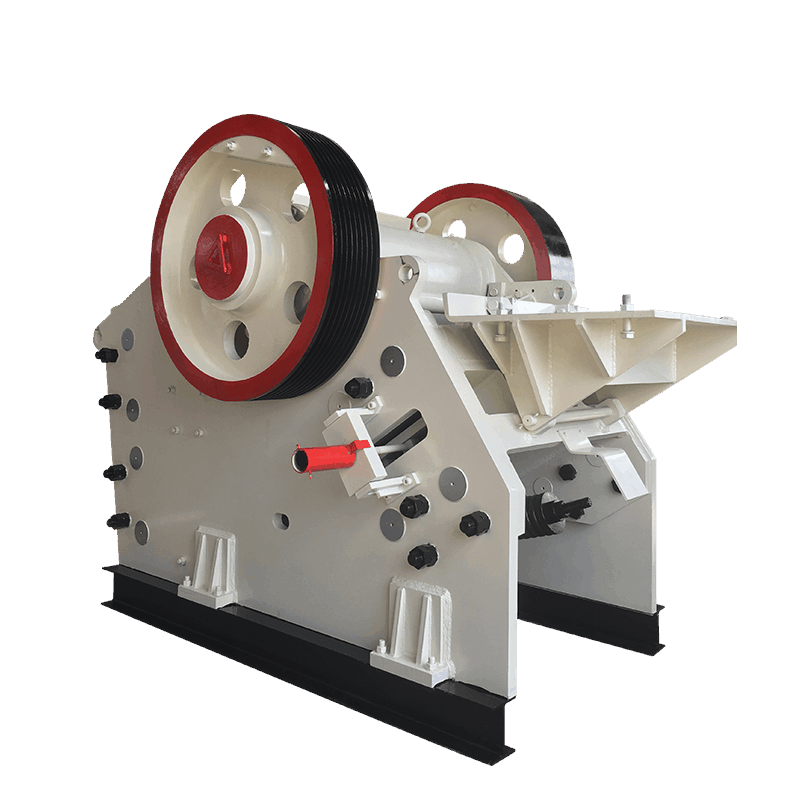

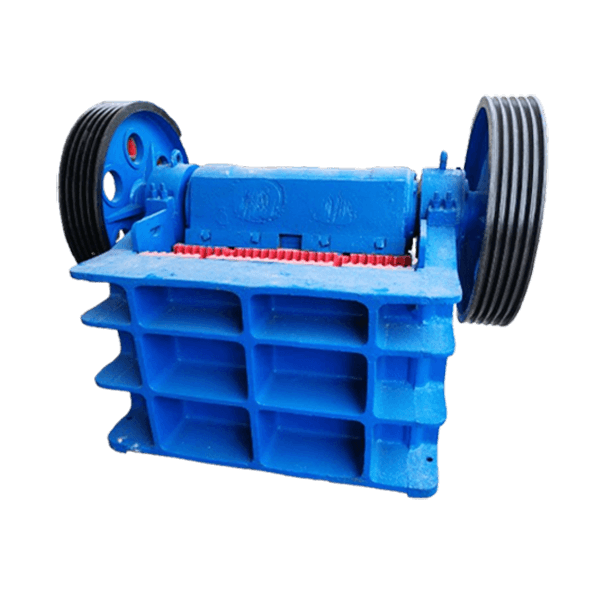

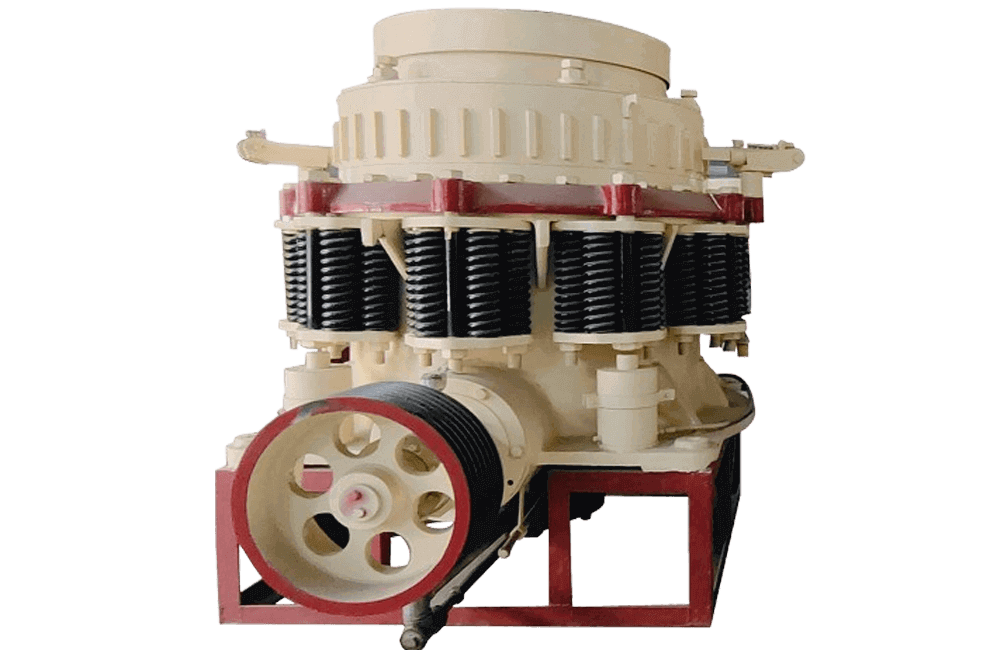

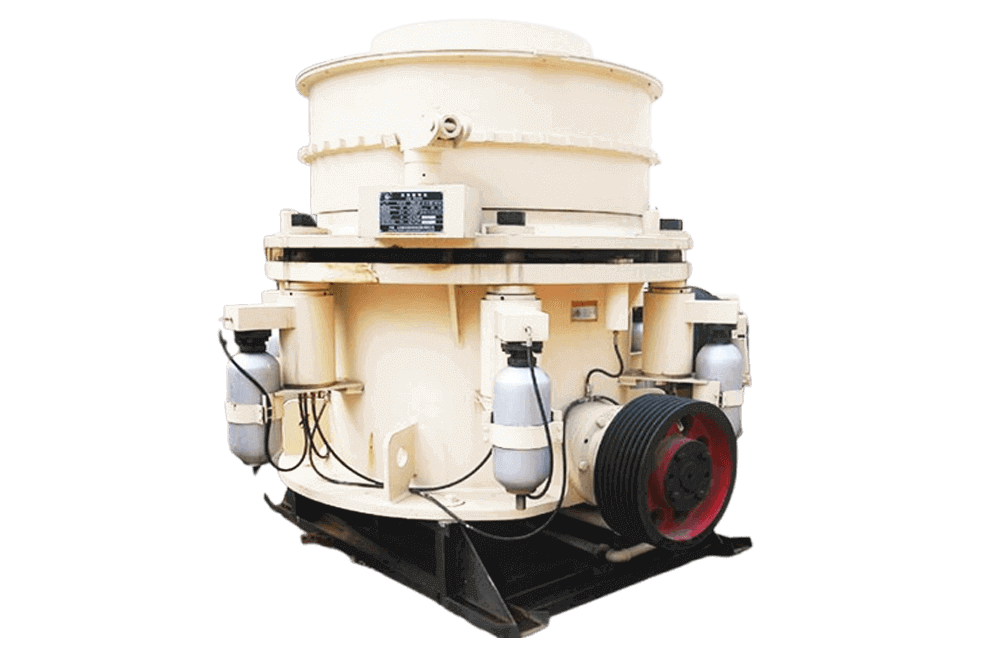

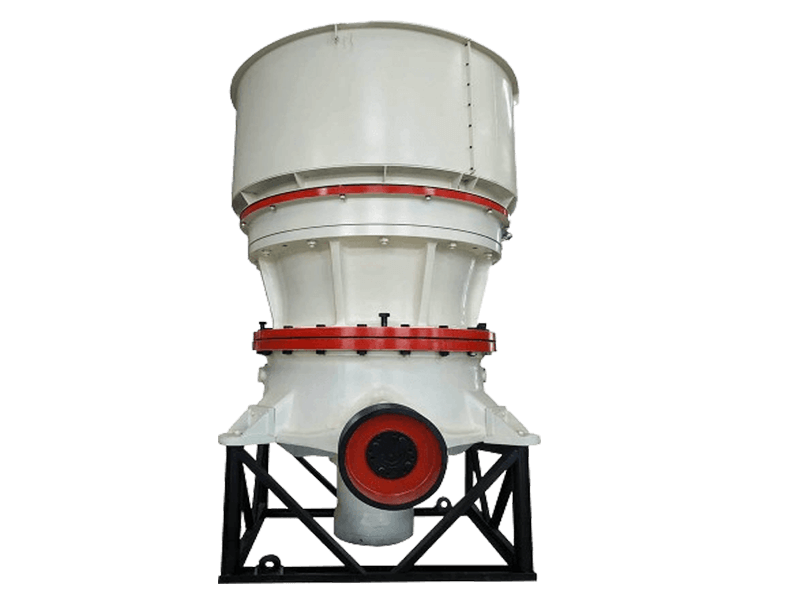

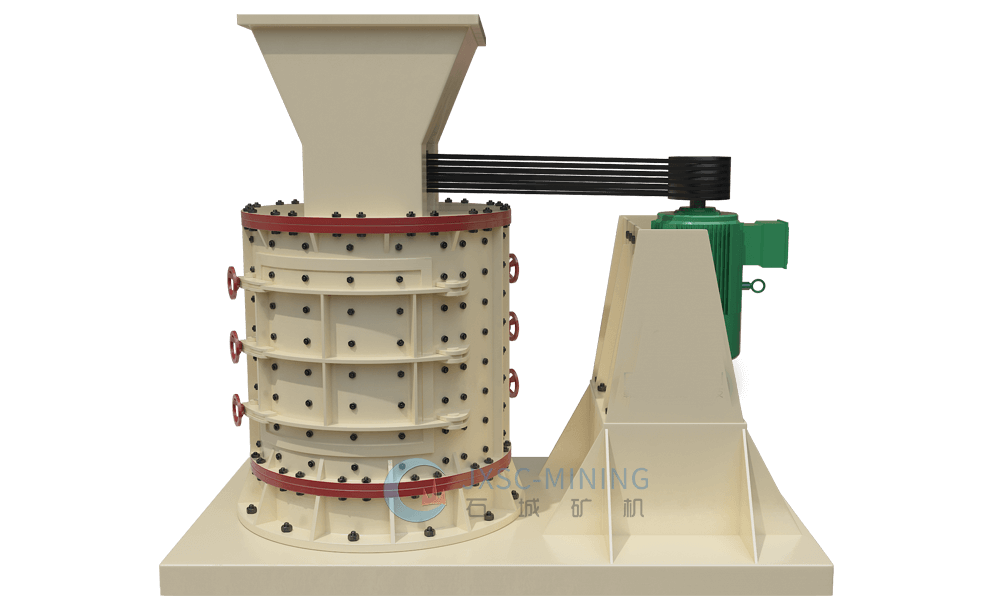

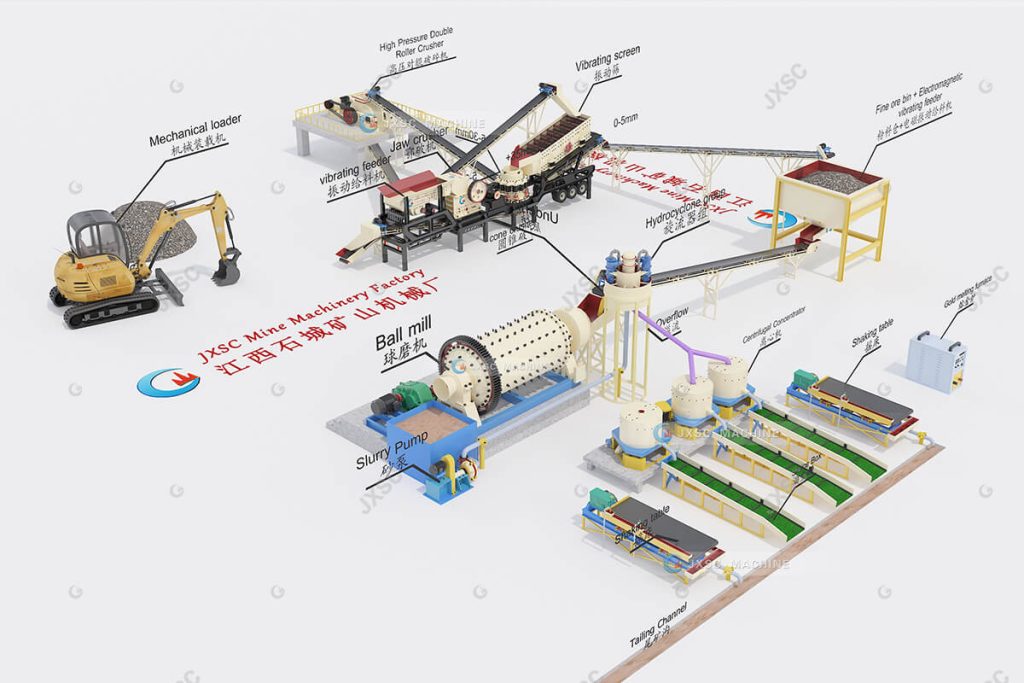

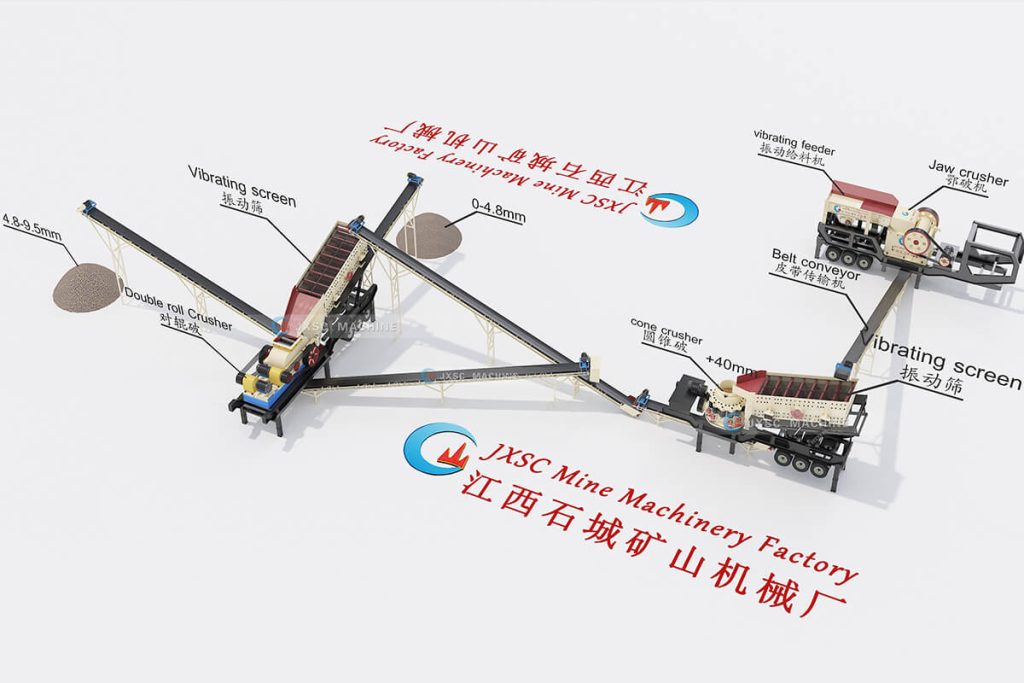

The core value of introducing crawler-type or wheeled mobile crushing equipment lies in enabling on-site processing of ore. These systems integrate feeding, crushing, screening, and conveying functions. The extracted raw ore is directly crushed into finished aggregate meeting specifications at the mine site. This modular design reduces transportation costs per ton by 40%, not only directly reducing the frequency and distance of transportation but also preventing losses of raw ore during transportation.

Benefit 2: Rapid Deployment and Flexibility

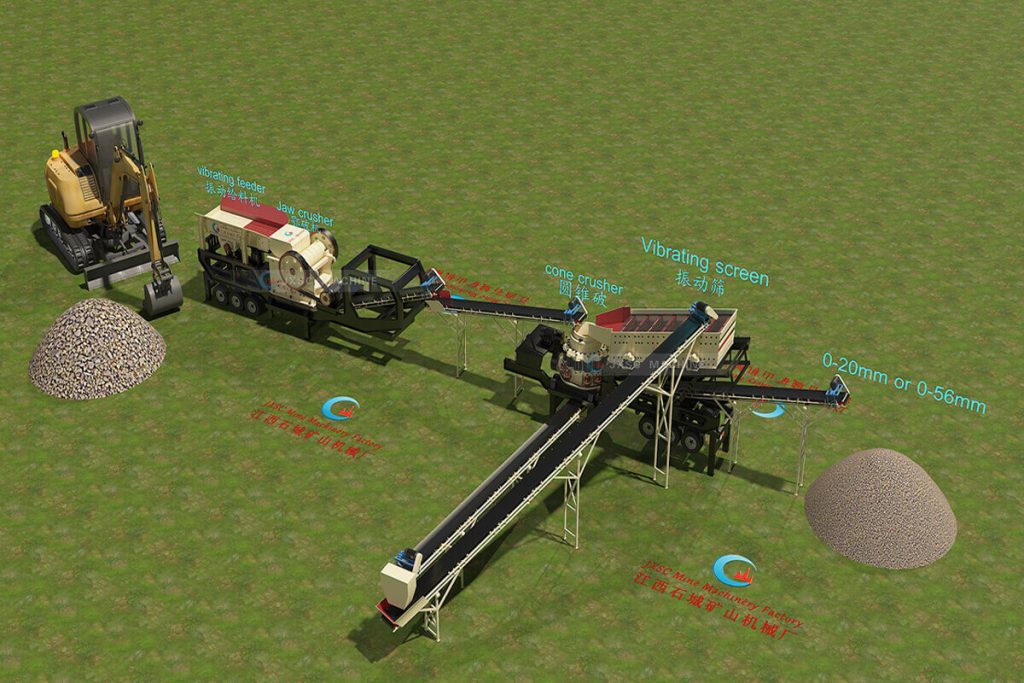

Traditional stationary crushing plants often require a series of complex procedures for installation, including foundation construction, equipment hoisting, and pipeline connection, typically taking 3-8 weeks to become operational. However, mobile crushing equipment can easily handle extreme mining environments such as mountains, deserts, and plateaus. Utilizing crawler or wheeled chassis, it possesses strong off-road capabilities and can operate stably on slopes up to 15°, eliminating the need for dedicated roads or extensive site leveling.

With a relocatable mobile ore crushing system, mines can begin production immediately at the start of the mining season. At the end of the season, the equipment can be quickly dismantled and moved, completely avoiding the significant waste of idle fixed facilities during the winter months. As the mining face advances, the mobile equipment can easily and flexibly follow the working face, maintaining the optimal operating distance.

Benefit 3: Improved Mining Efficiency and Production Capacity

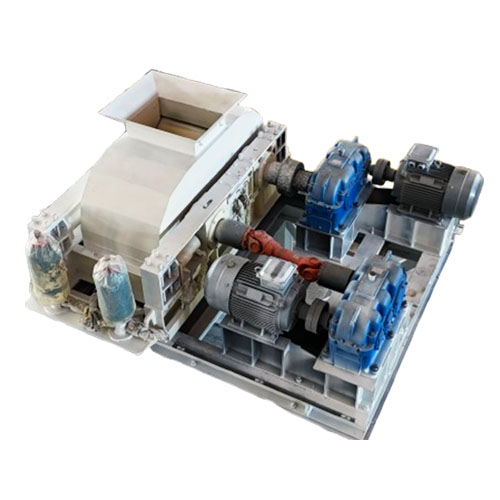

Modern mobile crushing equipment is generally equipped with intelligent control systems, featuring automatic feeding, load adjustment, and remote monitoring functions. They utilize an integrated design, combining crushing, screening, and conveying processes on a single platform, enabling continuous operation from ore extraction to finished product. Production capacity can be further increased through the parallel operation of multiple machines. Compared to traditional fixed production lines that require multiple material transfers, this completely eliminates the time-consuming intermediate steps of loading, unloading, and transportation, significantly increasing the effective operating time of the equipment.

Benefit 4: Environmental Compliance and Sustainable Development

In traditional mining operations, tailings typically account for 50%-80% of the total ore mined. Their storage and disposal not only occupy vast amounts of land but also pose environmental risks such as soil and water pollution. Mobile crushing plants, however, often utilize enclosed crushing chambers and negative-pressure dust removal systems to suppress dust generation at the source. During operation, both the feed and discharge ports are equipped with sealing devices, and in conjunction with high-efficiency bag filters, they can capture over 95% of dust particles. Simultaneously, the equipment’s soundproof enclosure and vibration-damping base reduce operating noise to below 85 decibels.

JXSC fixed & mobile ore crushing equipment is designed to reduce carbon emissions from vehicles, minimize dust and noise pollution, and optimize tailings management. This not only meets increasingly stringent environmental requirements but also provides a safer and healthier working environment for operators.

50 TPH Mobile Gold Ore Crushing Plant Process

100-150TPH Mobile Sedimentary Stone Crushing Plant

Customized Mobile Ore Crushing Plant Solution

Conclusion

Mobile ore crushing solutions have become a revolutionary solution in the mining industry due to their four core advantages: flexible deployment, high efficiency, low transportation costs, and environmental compliance. Whether for short-term mining operations, high-altitude mining areas, long-term production planning, or scenarios requiring flexible adjustments, modular equipment can significantly improve return on investment.

Want to customize the optimal ore crushing solution for your mine? We provide a full range of services, from equipment selection to intelligent operation and maintenance. Contact us today to get your exclusive ore crushing system!