With global copper demand continuing to rise, how can copper ore beneficiation efficiency be optimized? Copper ore is a core link in the metal smelting industry chain, the beneficiation plants bear the crucial mission of transforming low-grade ore into high-value concentrates. Their technological level directly determines resource utilization and corporate profitability. However, in actual production,copper beneficiation plants face multiple challenges, including fluctuating ore grades, equipment wear and tear, excessive energy consumption, and environmental compliance. This article will delve into the typical challenges in the copper ore beneficiation process and provide targeted, multi-dimensional solutions ranging from process optimization to intelligent upgrades.

Copper beneficiation plants often face challenges such as fluctuating recovery rates due to complex ore properties, low grinding and flotation efficiency, high operating costs, and environmental compliance. JXSC provides intelligent beneficiation solutions, including the selection of high-efficiency flotation reagents, upgrading of wear-resistant equipment, and tailings dry stacking technology, to improve copper concentrate grade and recovery rate, helping beneficiation plants achieve green and efficient production by 2025.

4 Core challenges of copper beneficiation plants

(1) Fluctuations in Ore Properties

Low-Grade Ore Processing:

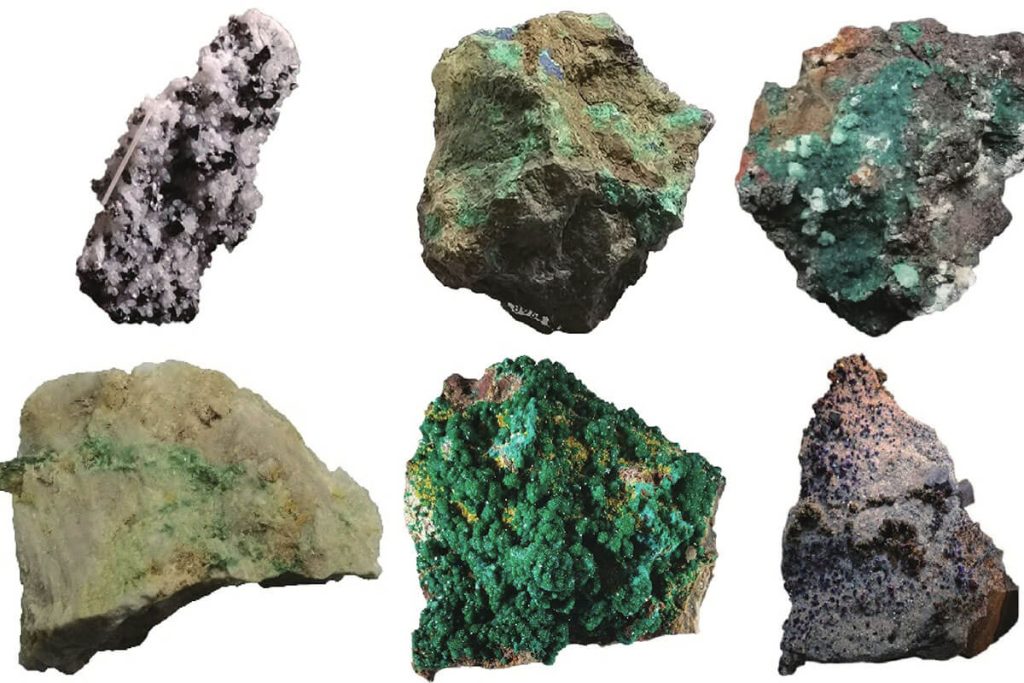

With the increasing depletion of high-quality copper resources, low-grade copper ore (Cu < 0.5%) has become the mainstream mining target. This type of ore not only has low metal content but also a high proportion of gangue minerals such as quartz and calcite, leading to increased energy consumption for crushing and flotation reagent consumption. Furthermore, low-grade ore is often accompanied by oxide and sulfide minerals (such as malachite and chalcopyrite), making it difficult for traditional flotation processes to recover both, resulting in copper metal loss.

Mineral Dispersion Characteristics:

When copper minerals are finely dispersioned or closely associated with pyrite, conventional grinding is insufficient to achieve individual liberation. For example, in the processing of porphyry copper ore, chalcocite is dispersioned in a “star-like” pattern within the silicate matrix, requiring the ore to be ground to -400 mesh (90% concentration) to meet separation requirements. However, such fine grinding easily generates slime, worsening the flotation operating environment. However, when processing fine-grained copper minerals (such as secondary copper sulfides), their large surface area makes them prone to adsorbing sludge and forming a “sludge cover,” which causes the flotation foam to become sticky and reduces the copper recovery rate by 5%-8%.

(2) Low efficiency of mineral processing flow

Overly coarse grinding can lead to insufficient liberation of copper minerals, affecting flotation recovery rates. Grinding too finely increases energy consumption and may cause mud formation, reducing flotation selectivity. In the copper ore flotation process, the selection and proportion of reagents are crucial. Inappropriate collectors (such as xanthates), depressants (such as lime), or frothers may lead to copper mineral loss or a decrease in concentrate grade.

(3) Environmental and tailings management

Global standards for heavy metal emissions are becoming increasingly stringent. Industrial pollutant emission standards require that the concentration of copper ions in discharged wastewater be ≤0.5 mg/L and arsenic ≤0.1 mg/L. Major environmental issues include the generation of acidic wastewater, heavy metal pollution, and safety risks associated with tailings storage. Sulfide minerals (such as pyrite) easily form acidic wastewater after oxidation, which, if discharged untreated, will pollute surrounding water bodies. Flotation tailings water often contains residual reagents, heavy metal ions, and suspended solids. Furthermore, traditional tailings dam construction requires a large amount of land and carries the risk of dam failure.

(4) High Operating Costs

The grade of copper ore resources has been declining year by year, while the mining depth has been increasing, leading to higher processing costs. In copper mines, ball mills have high unit energy consumption, consuming 60%-70% of the plant’s electricity in the crushing-grinding process. Reagent costs are significantly affected by fluctuations in ore properties; for example, when the mud content of the ore increases from 10% to 20%, the use of adjusting agents, coupled with imported environmentally friendly collectors, further exacerbates cost pressures. Labor costs may increase due to higher operational precision requirements; for example, the error range of manual dosing systems can lead to 3%-5% reagent waste. In addition, increasingly stringent environmental regulations have increased investment in tailings and wastewater treatment.

Targeted optimization solutions for copper beneficiation plants

1. Addressing Ore Complexity:

Pretreatment and Process Adaptation Technologies

For ores characterized by low grade, high impurities, and fine dissemination, a combined pretreatment and process adaptation approach is primarily employed. Pretreatment utilizes technologies such as X-ray diffraction, washing and screening to remove waste rock in advance, reducing ineffective grinding. Simultaneously, ore blending management mixes high- and low-grade ores, minimizing the impact of fluctuations on subsequent processes.

For complex and difficult-to-process copper ore beneficiation, combined processes (such as flotation-leaching) can be used to improve copper recovery. For example, a staged grinding and combined process can handle polymetallic symbiotic ores.

2. Improving Mineral Processing Efficiency:

Key Technology Optimization

In the copper ore beneficiation process, precise parameter control in the grinding and flotation stages is crucial for improving efficiency. Energy-efficient ball mills can be used, with intelligent sensors and automated systems to adjust the ball ratio, feed rate, and hydrocyclone parameters in real time. This ensures the grinding product meets particle size standards, avoiding over-grinding or under-grinding.

For flotation optimization, intelligent control systems can be introduced to automatically adjust grinding fineness and reagent dosage based on ore properties. Furthermore, a combined high-efficiency flotation column and mechanical flotation machines can improve the recovery of fine-grained copper minerals. Simultaneously, continuous research and development of new, efficient, and environmentally friendly flotation reagents is also key to improving separation efficiency.

3. Environmental Compliance:

Green Mineral Processing Technology

To reduce environmental impact, dry tailings storage can be implemented, such as tailings concentration and dewatering processes, and dewatering and stockpiling of tailings. High-frequency dewatering screens combined with filter presses can reduce the risk of wastewater leakage and facilitate subsequent ecological restoration. A closed-loop water recycling system can be constructed, using neutralization precipitation (lime to adjust pH) and flocculant treatment to remove heavy metals before reuse. High-salinity wastewater can be treated with evaporation crystallization or biological treatment technologies to ensure reduced fresh water consumption and compliance with discharge standards. Furthermore, tailings reprocessing technology can extract valuable ores, reducing tailings volume and generating additional revenue. For applications with extremely high environmental requirements, baghouse dust collectors and spray dust suppression devices can be installed at crushing and transfer points, and soundproof enclosures or silencers can be used in noise-sensitive areas. While environmental compliance is costly, it is a necessary condition for sustainable development in the long run.

4. Cost Reduction and Efficiency Improvement:

Intelligentization and Resource Recycling

Ways to reduce costs include optimizing the grinding media ratio, such as using high-chromium steel balls to extend their lifespan. Utilizing new energy sources, such as photovoltaic energy storage, can reduce grid power consumption. Furthermore, deploying drones or online instruments in inspection and testing processes can optimize operational configurations and reduce labor costs. Specifically, appropriately simplifying the process flow based on mineral characteristics can also reduce operating costs.

The core challenges of copper beneficiation plants encompass four main aspects: ore property fluctuations, grinding and flotation efficiency, environmental compliance, and cost control. Pretreatment processes, intelligent grinding and flotation technologies, and tailings dry stacking or reprocessing solutions can be employed, all measures feasible for conventional beneficiation plants. For customized copper beneficiation equipment and end-to-end solutions, contact JXSC immediately for one-stop customized beneficiation services including intelligent sorting, energy saving and cost reduction, and green mining!