How is iron ore converted into the 65%+ high-grade iron ore concentrate necessary for steel production? Iron ore, the “food” of modern industry, relies heavily on its processing efficiency to directly determine the quality and cost-effectiveness of steel. Direct smelting of raw ore not only consumes a lot of energy and pollutes the environment, but also reduces the strength of the steel due to excessive impurities. Therefore, from raw ore mined from the mine to concentrate meeting smelting standards (TFe > 65%), it must undergo multiple iron ore processing methods, including crushing, grinding, sorting, and dehydration. This article will provide a complete technical analysis of the entire process from ore to high-grade concentrate, guiding you to key solutions for improving recovery and reducing energy consumption.

The complete iron ore processing process encompasses crushing and grinding, magnetic separation, flotation, gravity separation, and other separation technologies, as well as concentration, filtration, and concentrate dewatering. Through this synergistic approach, the company achieves an iron ore concentrate grade of 65%-67.5% with a recovery rate exceeding 90%, providing mines with a high-value-added iron ore concentrate production solution.

Basic properties of iron ore

Iron ore, based on its mineral composition, is primarily classified into magnetite, hematite, and limonite, the three most common types used in industrial processing.

- Magnetite (Fe₃O₄) is highly magnetic and easily concentrated through magnetic separation. It is currently the most efficient type of ore, with a typical grade of 55%-65%.

- Hematite (Fe₂O₃) is less magnetic but has large reserves, requiring recovery through gravity separation, high-intensity magnetic separation, or flotation.

- Limonite (Fe₂O₃·nH₂O) has a high water content, resulting in an iron content of only 35%-50%, and is high in impurities (such as phosphorus and silicon). Therefore, additional dehydration prior to sintering is required to enhance its processing value.

- Additionally, carbonate ores such as siderite (FeCO₃) require roasting and decarbonization before effective utilization.

Note: Accurate identification of ore type through X-ray diffraction is essential before mine development; otherwise, the beneficiation process may be completely ineffective.

High-grade iron ore concentrate is a key raw material for steelmakers, helping them reduce smelting costs. Iron ore processing aims to enrich the raw ore through beneficiation while strictly controlling impurity levels to meet blast furnace smelting requirements. This process primarily involves a combination of crushing and grinding, gravity separation, magnetic separation, flotation, and concentration and filtration.

Core processes of iron ore processing

1. Iron Ore Mining and Pretreatment

Open-pit mining is suitable for deposits buried less than 300 meters deep and with thick ore bodies.

Underground mining is suitable for deep deposits buried more than 300 meters deep or with complex geological conditions.

- Hand sorting: Large waste rock is removed manually or through intelligent sorting equipment (such as AI-powered visual recognition). This process is suitable for initial ore purification and can reduce the inefficient load on subsequent crushing equipment by 30%.

- Ore washing: Because raw ore often contains a certain amount of clay, it requires washing before being fed into the crusher. Ore washers can effectively remove clay from the ore surface, leaving the ore clean. Commonly used equipment includes trough/log washers and spiral washers.

2. Iron Ore Crushing and Grinding

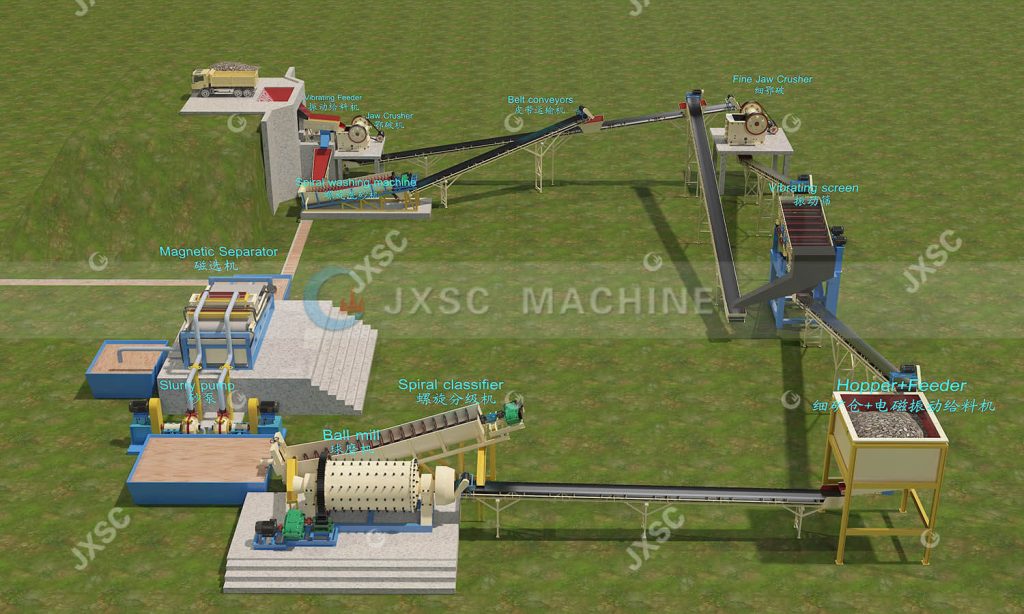

(1). Three-Stage Crushing Process (Coarse Crushing → Secondary Crushing → Fine Crushing)

The coarse crushing stage utilizes a jaw crusher, which provides a large feed size and is suitable for primary crushing in open-pit or underground mines. The secondary crushing stage utilizes a standard cone crusher for fine crushing, utilizing the principle of laminated crushing to minimize over-crushing, resulting in a product cubic content exceeding 85%. The fine crushing stage utilizes a short-head cone crusher or impact crusher, ensuring that the final product particle size of -25mm accounts for ≥90%, providing qualified raw material for the grinding stage.

Typically, a vibrating screen is installed after the fine crushing stage to return unqualified coarse particles to the fine crusher for further crushing, forming a closed “crushing-screening-return” cycle. This keeps the over-crushing rate below 8%. Furthermore, controlling energy consumption during the crushing process is crucial. Adjusting the crusher discharge port size can achieve “more crushing, less grinding,” reducing processing costs.

(2). Grinding Stage: From Particles to Mineral Powder

Ball mills achieve fine grinding through the impact and grinding action of steel balls. They are suitable for ores requiring deep disaggregation (element disaggregation > 90%), such as magnetite. Grate ball mills are commonly used. Rod mills, on the other hand, primarily utilize linear contact grinding with steel rods. They are suitable for processing hard ores such as hematite and limonite, minimizing over-grinding and ensuring a uniform particle size. They are typically used in the coarse grinding stage of stage grinding.

Both types of grinding equipment can be combined with a spiral classifier to form a closed-circuit system, achieving a grinding fineness of -200 mesh, representing 85%.

3. Iron Ore Separation Process

(1) Gravity Separation:

Gravity separation technology utilizes differences in mineral density to achieve efficient tailings removal during pre-concentration of low-grade ores. It is particularly suitable for limonite and hematite with coarse-grained particles (>0.5mm). Commonly used iron ore gravity separation equipment includes spiral chutes, shaking tables, and jig separators.

(2) Flotation:

For hematite (Fe₂O₃) or complex and refractory ores, reverse flotation is the most proven method for upgrading. Flotation primarily achieves purification by suppressing iron minerals and floating out gangue. Its reagent system requires precise matching of the mineral’s surface properties, with the core elements being the synergistic effect of collectors, depressants, and pH adjusters.

(3) Magnetic Separation:

Magnetic separation is the primary method for processing magnetite and is available in both wet and dry processes. Wet magnetic separators are suitable for deep separation of fine-grained minerals (<0.5mm) and are particularly effective in magnetite beneficiation. They can increase concentrate grades to over 65% with recoveries exceeding 90%. Dry magnetic separation, primarily used in arid regions or water-scarce mines, enables pre-selection of coarse particles, reduces waste rates by 30%-50%, and reduces energy consumption in subsequent grinding. This process can be used to process hematite, magnetite, and limonite, achieving recoveries of 85%-90%.

4. Iron Ore Concentration and Dehydration Stage

(1) Concentration and dehydration are key steps in reducing slurry moisture and improving subsequent filtration efficiency. Deep cone thickeners utilize gravity settling combined with compression zone pressure to achieve deep concentration of fine-grained slurries, achieving underflow concentrations of 65%-75% (magnetite) or 55%-65% (hematite). Inclined plate thickeners utilize an inclined array of parallel plates to shorten particle settling distances, making them suitable for rapid concentration of medium- and coarse-grained slurries.

(2) Filtration directly impacts filter cake moisture content (target ≤10%) and subsequent drying energy consumption. Vacuum filters (such as disc and drum types) utilize negative pressure to achieve solid-liquid separation, offering high throughput and continuous operation. They are suitable for initial dehydration of magnetite filter cakes, where moisture levels are typically 12%-15%, requiring a drying step for further reduction. Chamber filter presses utilize high-pressure dehydration and are particularly effective for dehydrating fine-grained hematite filter cakes.

(3) Drying process requires precise control of temperature and airflow to prevent agglomeration of the iron ore concentrate due to excessive moisture or localized overheating. For concentrates with stringent moisture requirements, rotary kilns or drum dryers may be considered.

Crushing, grinding, separation, concentration, and dewatering are key processes in iron ore processing. These include low-intensity magnetic separation of magnetite, high-intensity magnetic separation with reverse flotation of hematite, and combined gravity separation, magnetic separation, and flotation for polymetallic ores, helping to maximize iron concentrate grade and recovery. Different ore characteristics (particle size, mud content) require customized equipment combinations. Looking to reduce costs and improve recovery? Contact us for customized intelligent ore processing solutions, offering comprehensive technical support from equipment selection to parameter optimization.