Copper ore is generally an aggregate of copper sulfide or oxide and other minerals. The conductivity of copper is second only to silver, and it is more abundant and cheaper than silver. As one of the core materials required in the high-tech industry, copper has extremely high economic value. Copper ore processing plants also have a very high return on investment profit.

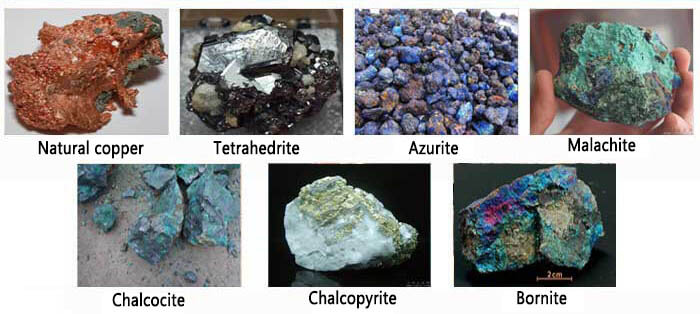

Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc. Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite.

If copper ore wants to be fully utilized, it must be processed by flotation. Flotation separation is an important copper ore beneficiation process in the current mineral beneficiation market. Only by determining the nature of the ore can we customize a suitable copper ore processing plant and equipment.

Copper ore Process

Copper ore is divided into sulfide ore, oxide ore and mixed ore according to its oxidation rate. The main technological process of copper ore is flotation. For refractory mixed copper ore and refractory oxide ore, hydrometallurgical process is generally used.

Copper ore beneficiation process is based on the physical and chemical properties of different minerals in copper ore. After the ore is crushed and ground, gravity separation, flotation, magnetic separation, electric separation and other ore beneficiation processes are used. Separate the useful minerals from the gangue minerals, and keep various paragenetic (associated) useful minerals separated from each other as much as possible. The process of removing or reducing harmful impurities to obtain raw materials for smelting or other industries.

Copper Processing Plant Flow

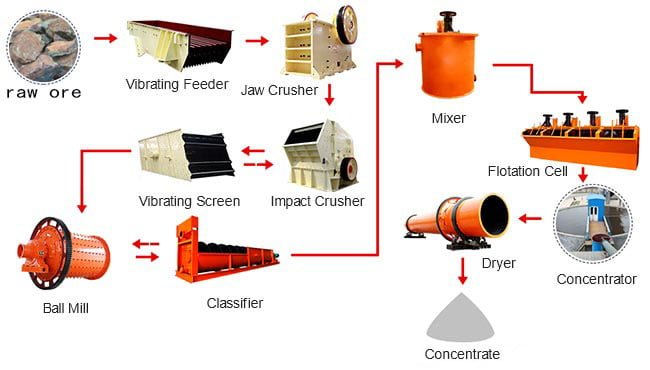

A single sulfide ore is usually treated by flotation process, using crushing-grinding-classification-flotation-concentration process to select a single copper sulfide ore as copper concentrate.

Copper ore beneficiation process The principle of priority flotation process is: crushing and screening→grinding and classification→priority flotation of copper concentrate→activation flotation of other concentrates→concentration and dehydration.

Copper ore beneficiation process The principle of mixed flotation process is: grinding and classification → mixed concentrate obtained by mixed flotation → concentrate separation and rough concentration → concentration and dehydration.

The copper ore positive flotation process is: crushing and screening, grinding and grading, roughing, selection, sweeping, concentration and dehydration.

Copper Processing Plant

Preparation process before separation

Including copper ore crushing, screening, grinding, grading and other processes. The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other

1. Crushing process

The copper ore that needs to be processed must first go through the crushing process. The vibrating feeder is fed through the silo, and the vibrating feeder is evenly sent to the jaw crusher for primary crushing, and the large raw ore is broken into small pieces of ore. After the coarse crushed copper ore is screened, it is sent to the cone crusher by the belt conveyor for intermediate crushing and fine crushing, and the ore is broken into smaller ore particles.

2. Grinding process

The copper ore processed into granules is screened by a vibrating sieve and sent to a ball mill for grinding and crushing. Here also need to use an auxiliary equipment – classifier. It can classify and screen copper ore and release copper ore powder that meets the requirements.

3. Screening and classification: According to the size of the sieve surface, the material is divided into different particle size grades, which is often used to process materials with coarser particle size. According to the different settling speeds of particles in the medium (usually water), the materials are divided into different equal-fall grades, called classification, which is used for materials with smaller particle sizes. Screening and grading are to separate the materials with suitable particle size during the crushing process, or to divide the materials into different particle size grades and select them separately.

4. Ore washing process: Ore washing is required to prevent the mud in the mud-containing mineral raw materials from clogging the crushing and screening equipment. If the raw materials contain soluble useful or harmful components, they should also be washed. Washing can be done as well as in screening and grading equipment.

Flotation Process

Because most copper minerals have good floatability, flotation is one of the commonly used beneficiation methods for copper ore. After the ground copper ore powder is sent to the flotation machine, various elements rich in it will react with various chemical solvents added in the flotation machine. The flotation machine separates the copper ore from the gangue, the attached metal minerals, the hydrophilicity of copper and other characteristics.

Concentrates and Tailings Processes

Including dehydration of various copper concentrates and tailings products, precipitation concentration, filtration, drying, washing and clarification of fine-grained materials, etc.

Most copper ore beneficiation products contain a lot of water, which is very unfavorable for transportation and smelting processing. Therefore, before smelting, it is necessary to remove the moisture in the beneficiation products.

1) Copper concentrate concentration is the action of gravity or centrifugal force, which makes the solid particles in the beneficiation products precipitate. In order to remove part of the moisture, the concentration is usually carried out in a thickener.

2) Copper concentrate filtration is the operation of making the ore slurry pass through a water-permeable and impermeable spacer layer of solid particles to achieve solid-liquid separation. Filtration is a further dehydration operation after concentration, usually on a filter.

3) Copper concentrate drying is the final stage of dehydration. It is an operation to reduce moisture based on the principle of heating and evaporation. But it is only used when the dewatering concentrate still needs to be dried. The drying operation is generally carried out in a dryer, and other drying devices are also used.

Copper Flotation Machine

Copper ore generally adopts flotation production line for beneficiation processing, among which copper ore flotation machine is the key equipment

- The copper ore flotation machine is designed through multi-stage separation tanks so that the entire flotation process is gradually completed, forming a cascade optimization. It satisfies the gradient change of the properties of the material when it is in different parts, and improves the separation accuracy.

- Copper ore powder flotation machine can guarantee better stability index for refractory and complex copper ore or high-grade concentrate. In the flotation process, the equipment parts wear less, the energy consumption is low, and the investment cost is low.

We support custom copper processing plant, flow design. JXSC is equipped with advanced equipment and high-quality mineral processing plant, high recovery concentrate rate, so as to achieve a win-win goal for customers.