How can the copper ore beneficiation industry overcome the dilemma of high energy consumption and low efficiency? Global copper ore resources are concentrating on low-grade, complex interbedded structures. Concentrators face challenges such as energy costs exceeding 30% and insufficient production of qualified ore fines. However, under the dual pressures of rising global energy prices and the “dual carbon” goals, energy-saving copper ball mills have become an inevitable choice. Focusing on core structural innovation and intelligent grinding process optimization, we are committed to providing mining companies with copper ore grinding equipment that combines policy compliance with economic benefits.

The energy-saving copper ore ball mill is a highly efficient grinding device designed for the high hardness and fine particle size of copper ore. Its graded grinding process reduces over-grinding and improves metal recovery when processing low-grade copper ore. This energy-saving ball mill can also be used in processing lines for lead, zinc, gold, manganese, and lithium ores. Combining policy compliance with cost advantages, it is a core grinding equipment for reducing costs and increasing efficiency in copper mineral processing.

What is an energy-saving copper ore ball mill?

The energy-saving copper ball mill is a highly efficient grinding machine developed specifically for the unique characteristics of copper ore resources. It significantly reduces energy consumption and improves grinding efficiency by optimizing its mechanical structure, transmission system, material wear resistance, and energy utilization. Its core principle is to combine modern energy-saving technologies (such as variable frequency drive, high-efficiency motors, and intelligent control systems) with the crushing capabilities of traditional ball mills to achieve efficient and low-energy grinding of copper ore, meeting the mining industry’s dual needs for environmental protection and cost control.

For example, when processing mixed copper sulfide and oxide ores, a “graded grinding + selective crushing” process can be employed to avoid metal loss caused by over-grinding.

Core Advantages:

- Reduced Energy Consumption and Costs: In copper ore beneficiation, the grinding process typically accounts for 40%-60% of total energy consumption. Energy-saving copper ore ball mills can reduce energy consumption by 15%-30% through design optimization (such as reducing ineffective friction and improving liner shape) and the use of high-efficiency motors, directly reducing electricity bills.

- Improved Resource Utilization: Energy-saving ball mills, when combined with classifying equipment (such as cyclones), achieve finer particle size control and increase copper metal recovery rates.

- Environmental Protection: Low energy consumption directly reduces carbon emissions, noise, and lubricant pollution, meeting green beneficiation standards.

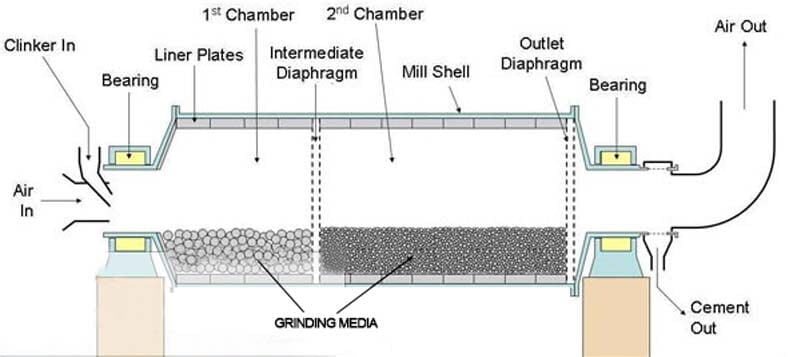

Working Principle

A motor drives the drum at a critical speed through a reduction gear. As the drum rotates, the grinding media inside is carried to a certain height and then thrown or slid down, causing impact crushing (primarily coarse crushing) and grinding (fine grinding) on the ore. The crushed ore slurry is discharged through the discharge port and enters subsequent separation processes (such as flotation).

Energy-Saving Copper Ore Ball Mill Structure Analysis

1. Feeding System:

The twin-screw feeder uses symmetrically spaced spiral blades to evenly distribute the ore, reducing feed impact by 30% compared to traditional single-screw feeders. Its “buffered feed” design prevents large ore chunks from directly impacting the drum wall, reducing energy consumption and minimizing “empty grinding” caused by uneven feeding.

2. Cylinder Design

As a core grinding component, the cylinder’s material and structure directly impact energy consumption and lifespan. Cast from high-chromium alloy steel, the cylinder boasts 2-3 times greater hardness and wear resistance than traditional high-manganese steel, reducing the frequency of downtime and replacement due to wear. Furthermore, the cylinder’s wall thickness has been optimized through finite element analysis, resulting in a 12-15% weight reduction while maintaining strength, thereby reducing ineffective rotational energy consumption.

3. Drive System

The energy-saving ball mill utilizes an innovative combination of a permanent magnet synchronous motor and a planetary gear reducer, resulting in an 8-10% increase in efficiency compared to traditional asynchronous motors. This enables high torque at low speeds.

4. Liner and Grinding Media

The liner shape and grinding media gradation determine grinding efficiency: The corrugated liner, with its concave and convex patterns, alters the trajectory of the steel balls, increasing impact crushing force by 15%, making it suitable for coarse grinding. The hyperbolic liner increases the grinding contact area, increasing the -200 mesh ore yield to 82% in fine grinding.

The grinding media utilizes a mixed gradation of high-chromium steel balls and alumina ceramic balls.

5. Discharge System

A grid-type discharge device is suitable for coarse grinding, reducing over-grinding through forced discharge. An overflow type is suitable for fine grinding. For copper tailings treatment, a spiral classifier or hydrocyclone is recommended, which can increase metal recovery by 5-8% (especially for low-grade ores).

6. Variable Frequency Drive Technology

The machine can be equipped with a PLC variable frequency drive system, which automatically adjusts the speed based on the ore feed rate, ensuring maximum energy utilization and avoiding energy waste from over-grinding or idling.

Copper Ore Grinding Flow

The copper ore grinding process is a key step in the copper beneficiation flow, primarily used to crush the ore to an appropriate particle size for subsequent flotation or leaching. The following are the most common steps in the copper ore grinding process:

(1). Copper Ore Crushing

Mined ore is crushed into smaller particles using tools such as jaw crushers, hammer crushers, and impact crushers. Substandard ore is recycled through closed-circuit screening (vibrating screens) to ensure uniform particle size and prepare for subsequent grinding.

(2). Copper Ore Grinding

The crushed ore is finely ground to release the copper minerals. Typically, a ball mill is combined with a spiral classifier or cyclone in a closed circuit for fine grinding. For ore requiring further separation, grinding to <0.074 mm (200 mesh) can be performed using a secondary grinding stage to improve flotation recovery.

Qualified fine-grained ore pulp (with a minimum -200 mesh percentage) is fed to flotation cells and other separation equipment. Substandard coarse particles are returned to the secondary ball mill for further grinding, forming a closed-circuit “grinding-classification-regrinding” cycle.

(3). Copper Ore Separation Process

Flotation (using surface hydrophobicity differences to separate minerals), supplemented by gravity separation, magnetic separation, or chemical leaching (for low-grade ores).

- Gravity/magnetic separation: Used for gravity separation of coarse ores or removal of magnetic impurities (such as pyrrhotite).

- Copper Sulfide Ore Flotation: Collectors and frothers are added to separate copper minerals (such as chalcopyrite and bornite) in a flotation cell. The coarse concentrate can also be refloated to improve copper grade and achieve high recovery rates.

- Copper Oxide Ore Processing: Leaching is primarily performed using sulfuric acid/ammonia solutions, followed by extraction enrichment, and electrolysis to produce 99.99% cathode copper.

- Mixed Ore Processing: Float the sulfide ore first, then treat the oxide ore (or leach it).

(4). Concentrate and Tailings Processing

The concentrator increases the concentration of the flotation concentrate to 60%-70%. A vacuum filter or filter press is used to dewater the concentrate to 8%-12% moisture. Dryers can also be used for special needs. The purpose is to reduce the moisture content of the concentrate to facilitate transportation and smelting. If necessary, the concentrate can be stored in a tailings pond, dry-stacked, tailings reprocessing or the tailings water can be recycled.

Our energy-saving copper ore ball mill utilizes optimized structures such as a high-chromium, wear-resistant cylinder and planetary gear transmission, combined with a graded grinding process, to achieve reduced energy consumption and increased efficiency. Complex ores utilize combined processes (such as flotation-leaching) based on ore properties and composition analysis. For customized ball mill systems or to optimize existing production lines, please contact us for one-stop energy-saving mineral processing equipment and solutions!