Still worried about the efficiency of alluvial gold mining? Placer/alluvial gold mining, as a long-standing gold panning method, is still widely used around the world, especially in rivers, riverbeds, and alluvial plains. However, with thinning ore layers and increasingly stringent environmental requirements, efficient placer/alluvial gold mining equipment has become a key factor in determining profitability. This article will systematically outline a list of efficient equipment for the entire placer gold mining process, analyzing the key selection points for each stage from ore washing and screening pretreatment to purification, helping you optimize your mining process and maximize profits.

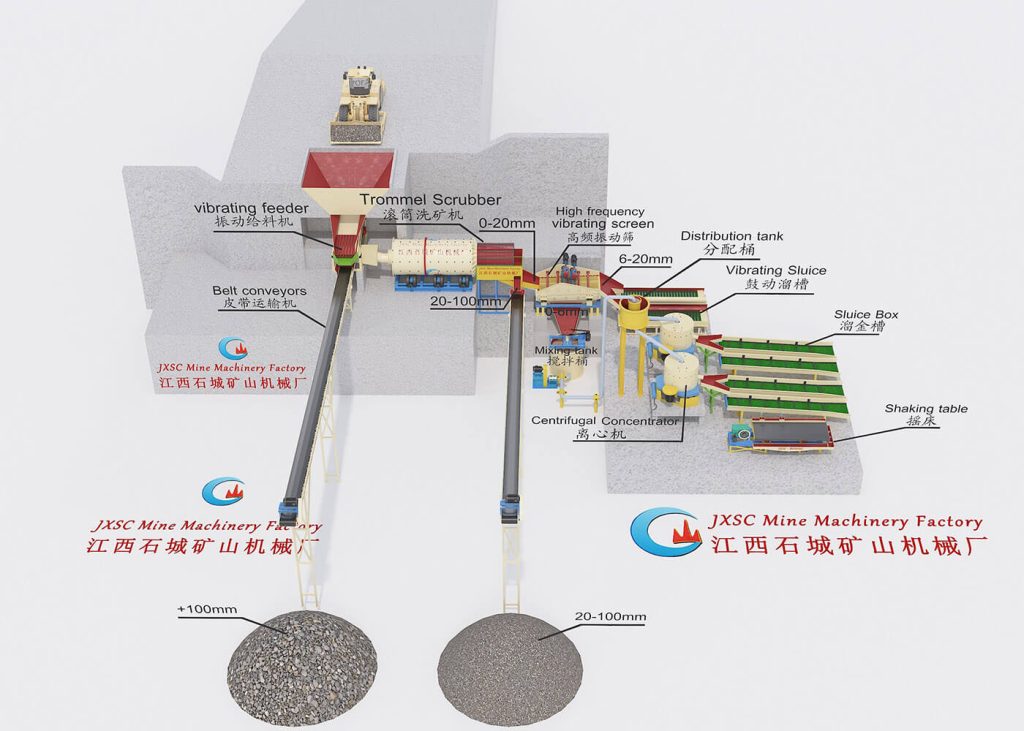

Placer gold resources are mostly found in river alluvial deposits and terraces, characterized by their wide distribution and ease of extraction. High-efficiency alluvial gold mining equipment mainly includes machines for pretreatment, screening, washing, gravity separation, and refining. Mobile placer gold mining equipment adopts a modular design, making it an ideal choice for small to medium-sized placer gold mining. The complete set of equipment can adapt to diverse needs from small to large-scale placer/alluvial gold mining.

List of placer/ Alluvial gold mining equipment

1. Placer Gold Pretreatment Equipment

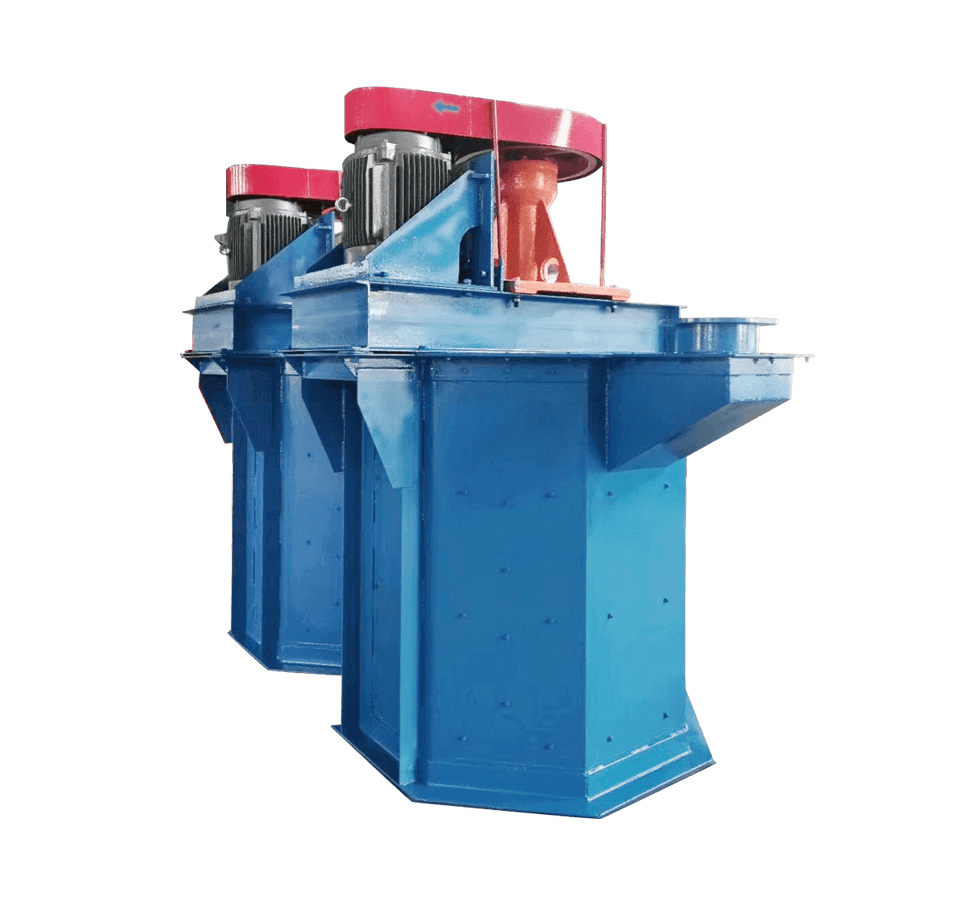

(1) Feeding Equipment: Vibrating Feeder

The feeding equipment is a key auxiliary equipment in the placer gold production line. Its main function is to uniformly and continuously transport the raw materials to the next process, avoiding blockages or overloads caused by uneven feeding. The GZD series vibrating feeder adopts a double eccentric shaft excitation structure and is suitable for the pretreatment of placer gold containing clay or large gravel.

(2) Screening Equipment: Vibrating Screen

Placer gold slurry often contains impurities such as gravel and clay lumps. High-efficiency separation is achieved through screening equipment during the pretreatment stage.

Vibrating screens are divided into linear vibrating screens and circular vibrating screens. The linear screen generates linear motion through dual-motor excitation and is suitable for rapid classification of coarse sand. The circular screen, utilizing a three-dimensional vibration trajectory, can process fine sand with high mud content. The screen mesh can be selected according to the characteristics of the ore. Both are suitable for placer gold with low mud content (such as river placer gold and dry riverbed ore) and are often used in conjunction with equipment such as sluices and centrifuges as the first process in the mineral processing flow.

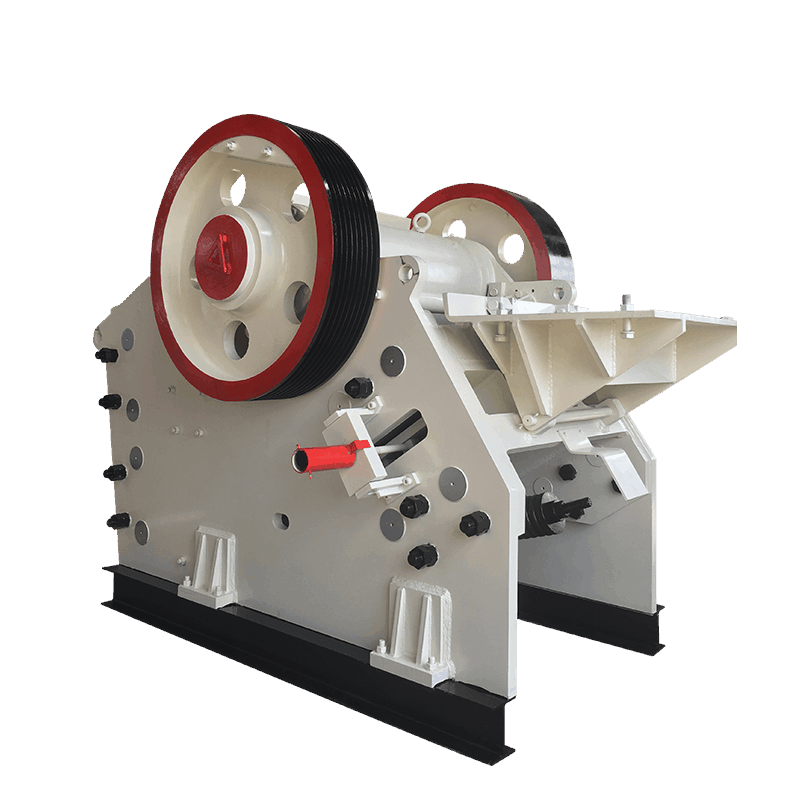

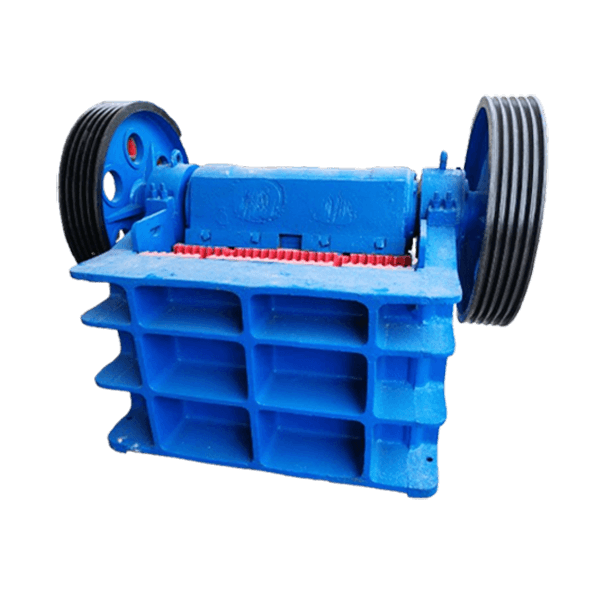

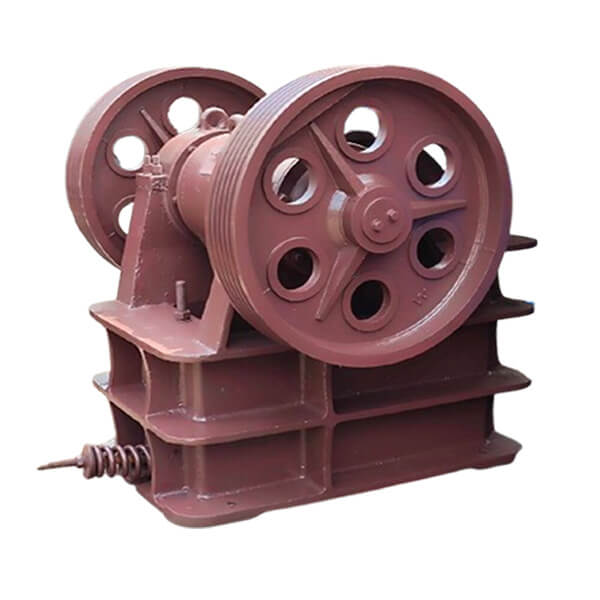

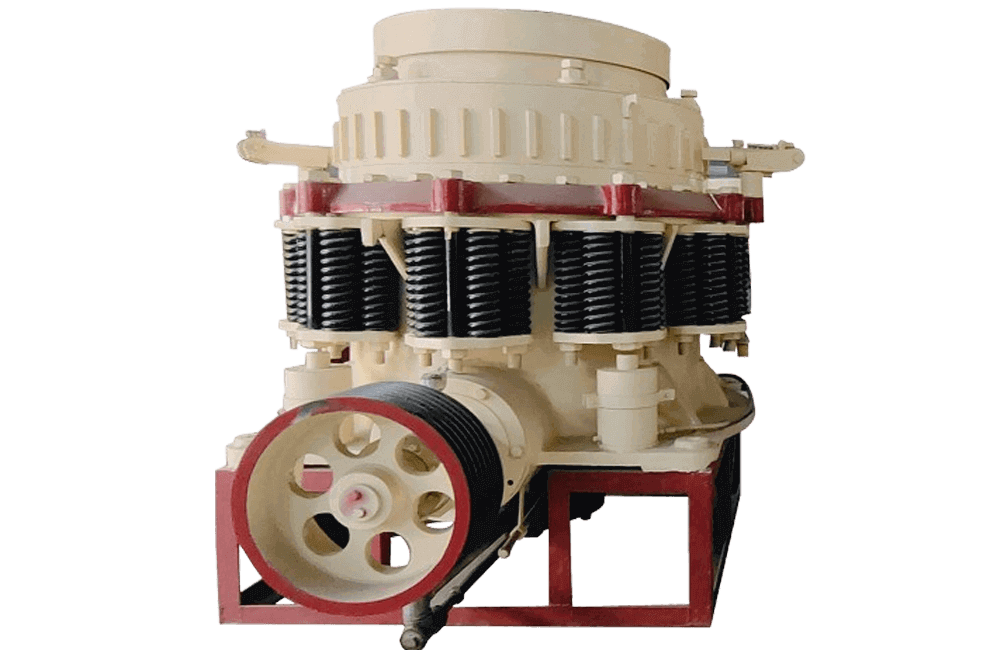

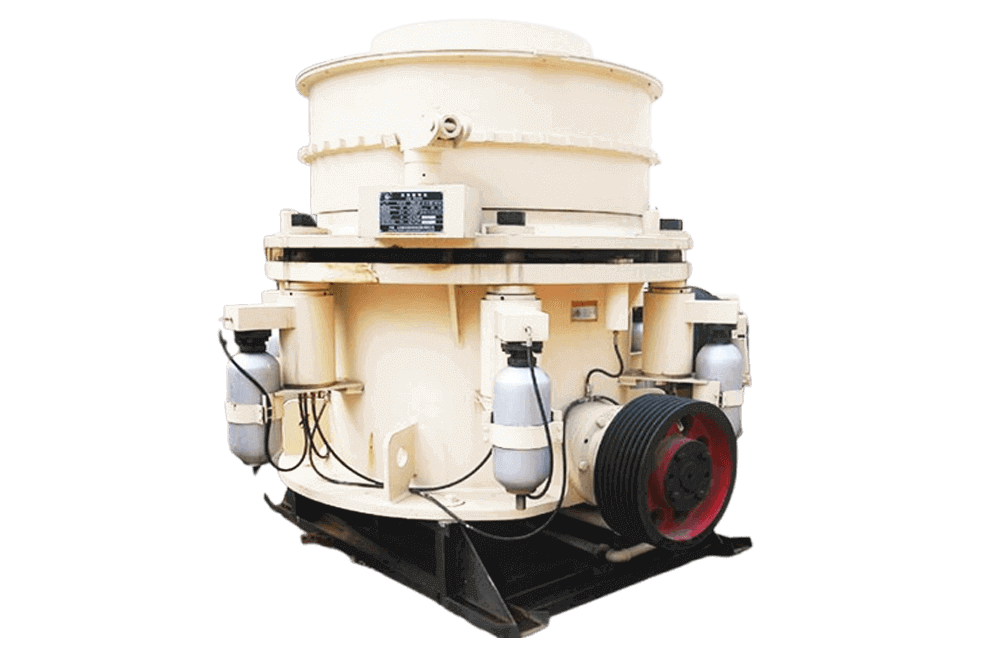

(3) Crushing equipment

For large-diameter gravel in sand mines, mineral crushing equipment such as jaw crushers and hammer crushers are usually used to reduce the particle size of the material to below 20mm, providing qualified ore for subsequent washing and beneficiation.

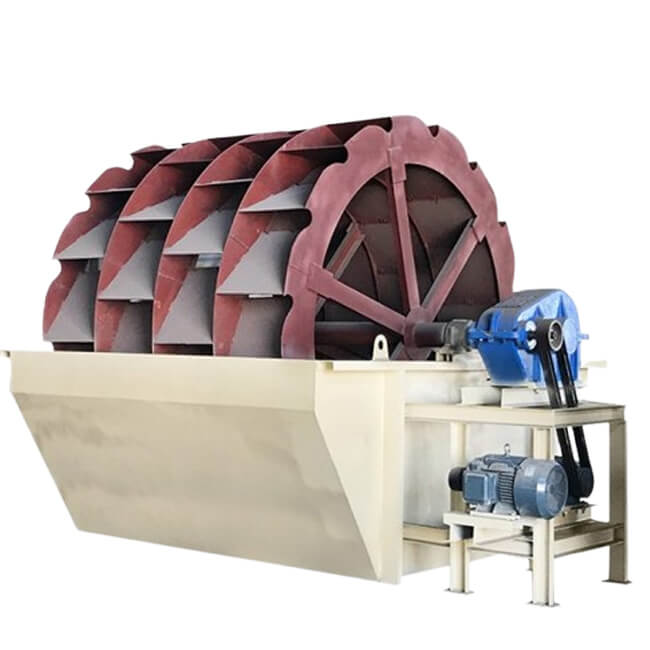

2. Alluvial Gold Washing Equipment

(1) Trommel Screen (Placer Gold Separation Equipment Without Clay)

The trommel screen combines screening and washing functions. Through drum rotation and water flow, it removes clay and silt from the ore, while simultaneously classifying different particle sizes of sand. It features a self-cleaning design and a built-in spray system to prevent screen clogging. Its screen can be quickly replaced with different aperture sizes. Suitable for placer gold mines with low clay and cementing content (such as dryland placer mines and weathered strata), it is often used as washing equipment for small and medium-sized alluvial gold mines with little clay in Africa, with a processing capacity of 1-200 t/h, and is used in conjunction with gold sluices or centrifuges.

(2) Rotary Scrubber (Alluvial Gold Mine Washing Equipment with High Mud Content)

The rotary scrubber can remove clay and organic impurities from the ore, preventing fine gold particles from being trapped and lost. Its drum wall is lined with wear-resistant rubber plates, and combined with a high-pressure spray system, it achieves efficient scrubbing, with a washing rate of over 95%. It is mainly suitable for cleaning placer gold deposits with high mud content (>15%), such as laterite placer deposits and clayey ore layers.

3. Alluvial Gold Gravity Separation Equipment (Key Link in Alluvial Gold Separation)

(1) Sluice Box Equipment

- Fixed sluice boxes mainly utilize gravity and friction to collect coarse gold particles. The slurry flows along the inclined sluice surface, and heavy minerals (gold) settle on the rough surface at the bottom of the sluice box (such as a blanket or grooved copper plate). It is inexpensive and requires no power, but the concentrate needs to be cleaned regularly during use. It is mainly suitable for the recovery of coarse gold particles.

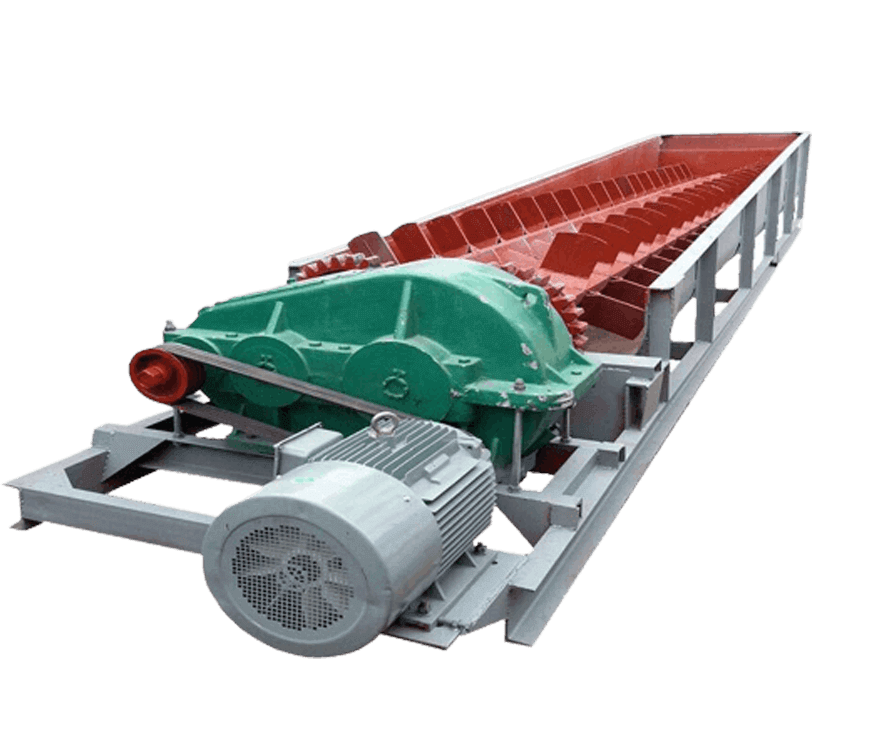

- Vibrating sluice boxes efficiently recover medium and fine gold particles, overcoming the caking problem of traditional sluice boxes. Its rubber bottom plate vibrates periodically up and down, breaking up the mineral sand sediment layer and enhancing gold particle settling. It is mainly used in river and dryland placer deposits with moderate mud content, achieving a recovery rate of over 95%.

- Spiral chutes can continuously separate fine gold particles from heavy minerals (such as magnetite and ilmenite). The slurry flows along the spiral sluice surface, and under the combined action of centrifugal force and gravity, gold particles accumulate towards the inner side of the sluice box. It is mainly used in the beneficiation stage to separate minerals with similar specific gravities and is suitable for the recovery of fine gold particles. (2) Centrifugal Concentrator

(2) centrifugal concentrator

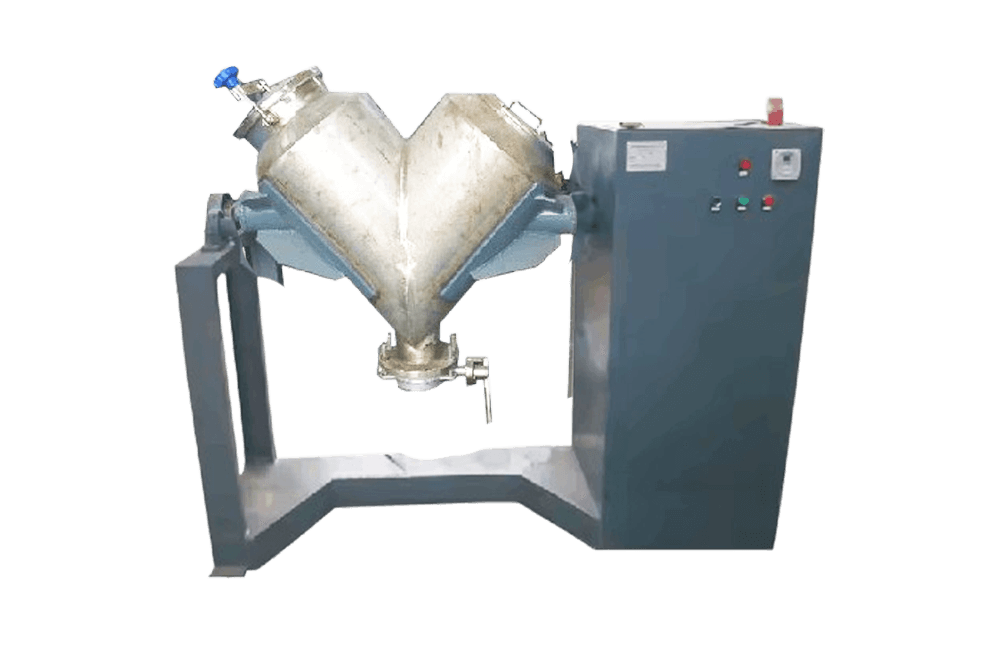

The centrifugal concentrator is the core gravity separation equipment for high-grade placer gold recovery. It mainly utilizes centrifugal force to separate gold particles from gangue. Its high-speed rotating drum generates centrifugal force, forcing heavy minerals (gold) in the slurry to settle rapidly on the drum wall, while light minerals are discharged with the tailings. Centrifugal concentrators are suitable for the beneficiation stage of various placer gold mines, especially for ores containing fine gold (such as weathered placer deposits and tailings reprocessing). They are often used in conjunction with gold sluices and shaking tables, achieving a recovery rate of 95%+.

(3) Jig Separator

The jig achieves mineral stratification through vertical alternating water flow, rapidly recovering coarse gold particles (0.5-5mm). It has a large processing capacity and strong adaptability. Utilizing the periodic up-and-down pulsation of the underflow water, the mineral particles are stratified according to density. Heavy minerals (gold) pass through the screen holes at the bottom and enter the concentrate tank, while light minerals are discharged with the water flow. Jigging machines are suitable for processing alluvial gold ore with a high proportion of coarse gold particles (such as alluvial fan deposits and ancient riverbed deposits). They can be used as roughing equipment in combination with centrifuges and shaking tables to form a combined process.

(4) Shaking Tables

Shaking tables utilize an inclined bed surface to perform asymmetrical reciprocating motion. Lateral water flow washes the ore layer, causing gold particles, due to their high density, to settle longitudinally along the bed surface, while lighter minerals are discharged laterally. It can accurately separate gold from heavy minerals with similar specific gravity (such as pyrite and garnet), increasing the concentrate grade to over 90%. Shaking tables are suitable for the final purification of all placer gold deposits, especially for processing the rough concentrate produced by centrifuges and sluices.

4. Alluvial Gold Refining Equipment

(1) Amalgamation Machinery

This equipment utilizes the affinity between mercury and gold to form amalgams for purification. It employs both internal and external amalgamation methods. External amalgamation uses a mercury-coated copper plate to adsorb gold particles, while internal amalgamation involves simultaneous grinding and amalgamation within a mill, achieving a recovery rate exceeding 98%. A mercury vapor recovery device is required to prevent contamination. This method is suitable for high-purity gold extraction.

(2) Gold Melting Furnace

The gold melting furnace is the final refining equipment in placer gold mining. It uses medium-frequency induction heating technology, combined with graphite or quartz crucibles, to rapidly raise the furnace temperature to the melting point of gold, causing the metal to generate eddy currents and melt. Finally, the molten gold is poured into a mold via a tilting device, and after cooling, it forms finished gold ingots with a purity ≥99.9%. It is mainly used for refining placer gold concentrate and producing high-purity gold ingots.

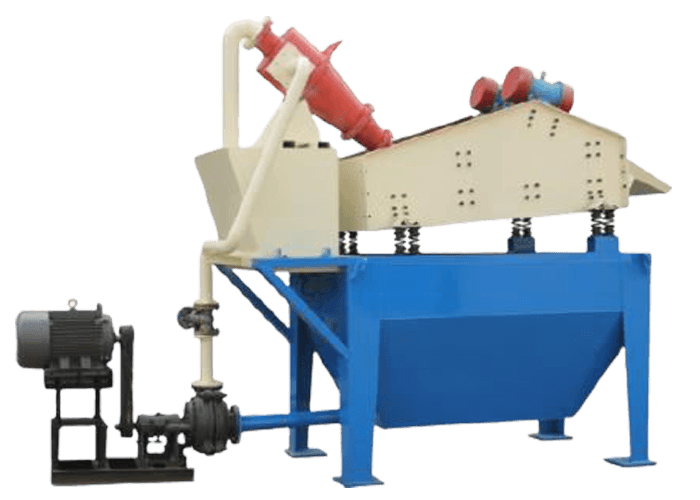

5. Mobile and Integrated Alluvial Gold Equipment

(1) Mobile Gold Wash Plant

This gold wash plant is an integrated system developed for small and medium-sized placer gold mines. Its core consists of a modular combination of a rotary scrubber/trommel screen and a sluice box system. The processing capacity is typically 1-300 tons/hour. JXSC supports customized fixed or mobile systems, suitable for placer gold processing in dispersed mining areas such as river channels and dry land.

(2) Mobile Jig Plant

The mobile jig plant is a specialized equipment for the efficient recovery of coarse gold particles. Its core configuration is an integrated system of a two-stage rotary drum pretreatment unit and a diaphragm jig. It is mainly designed for processing coarse gold, diamond ore, and associated heavy minerals in placer mines. The processing capacity can reach 1-20 tons/hour, with a recovery rate exceeding 90%, making it particularly suitable for coarse gold-rich areas such as alluvial fan mines and ancient river channel mines.

(3) Gold Dredger

A gold dredging vessel is a combined waterborne operation equipment integrating mining and mineral processing. It comprises a floating combined unit integrating excavation, screening, mineral processing, and tailings disposal, achieving integrated mining and processing of placer gold in river channels. The equipment can be equipped with an excavation system (chain bucket/dig bucket), drum screen/washing machine, vibrating screen, gold trough, centrifugal concentrator, and shaking table module. It can also be designed to form a mobile micro gold mineral processing plant, allowing for flexible relocation of operations. It is mainly suitable for placer gold mining operations in rivers, reservoirs, lakes, and shallow sea basins.

How to quickly improve the efficiency of placer gold mining? Equipment selection is key! The core process typically involves: screening pretreatment, gravity separation (gold sluice/jigging machine), fine separation and purification (centrifuge/shaking table), and smelting, all integrated into a fully automated process. Whether you are an independent gold prospector or a small mining team, choosing gold mining equipment requires balancing throughput, recovery rate, portability, and environmental compliance. Our experienced engineering team will provide you with one-on-one technical guidance. Contact us for a customized alluvial gold beneficiation solution!