As easily processed copper ore resources gradually deplete, why has refractory copper ore become a core issue for the global copper mining industry in 2025? Refractory copper ore typically refers to copper ore resources whose complex mineral composition, fine grain size, or the presence of harmful impurities lead to low efficiency in conventional beneficiation processes. Industry forecasts predict that refractory copper ore will account for over 35% of the global copper ore market by 2025, making its efficient development crucial for ensuring copper metal supply. This article will systematically analyze three main types of refractory copper ore: sulfide-type refractory copper ore, oxidation-type refractory copper ore, and mixed complex refractory copper ore. It will deeply analyze their typical mineral characteristics and the current processing challenges, and focus on proposing the latest solutions and technological trends for 2025 to help solve the processing problems of low-grade, complex ores.

The development of refractory copper ores—sulfide, oxide, and mixed copper ores—has become a focal point in the industry. Traditional processing methods face severe challenges such as low recovery rates, high energy consumption, and environmental pollution. The good news is that advanced copper ore processing technologies combining intelligent flotation, gravity separation, leaching, and electrolytic extraction are gradually solving these problems, improving recovery rates while reducing environmental risks.

3 Main Types of Refractory Copper Ores

(1). Sulfide-type Copper Ores

Sulfide-type difficult-to-process copper ores are currently a major challenge in industrial processing. Typical examples include arsenic-bearing copper sulfide ores (such as arsenopyrite-chalcopyrite co-occurrences) and fine-grained disseminated sulfide ores (such as chalcocite-pyrite intergrowths).

Reasons for processing difficulties:

Arsenic-bearing copper sulfide ores typically contain 0.5%-2% arsenic, and arsenopyrite and chalcopyrite exist as micron-sized intergrowths. The disseminated particle size is mostly less than 0.05 mm, making individual particle liberation extremely difficult. Mineral surfaces are prone to oxidation, reducing the adsorption efficiency of xanthate collectors. Simultaneously, the inhibitory effect of traditional depressants on pyrite can “cross-infect” chalcopyrite, resulting in flotation separation efficiency generally below 60%.

(2). Oxidized copper ores

The most common copper oxide minerals are malachite and azurite, followed by chrysocolla and cuprite. Sometimes copper sulfates and other soluble salts are also encountered. Their mineral structure and chemical properties directly lead to processing difficulties.

Reasons for difficulty in beneficiation:

The loose mineral structure results in over-grinding exceeding 20% during grinding, with slime accounting for 15%-25%, hindering leaching agent penetration. Soluble salts react with sulfuric acid, causing fluctuations in the pH of the leachate and high reagent consumption. These characteristics lead to high sulfuric acid consumption during leaching, 2-3 times that of easily beneficiated oxide ores. Iron ion hydrolysis forms hydroxide precipitates, clogging mineral pores, and copper dissolution rates are generally below 50%.

(3). Mixed and complex copper ores

Mixed and complex refractory copper ores are considered “tough nuts to crack” in processing due to their diverse mineral composition. They mainly include sulfide-oxidation mixed ores and copper ores containing carbonaceous/clay minerals. In the former, sulfide ores require flotation, while oxidized ores require leaching; however, differences in pulp pH lead to poor compatibility of combined processes.

Reasons for Difficulty in processing:

Sulfide ores require alkaline flotation, while oxidized ores require acidic leaching. Repeated pH adjustments increase reagent consumption. In the latter, such as carbonaceous copper ores, the carbonaceous minerals adsorb over 90% of the collector, resulting in twice the reagent consumption of conventional ores. Clay minerals swell upon contact with water, reducing the pulp concentration from 35% to 25%, impacting separation efficiency.

3 core challenges of processing refractory copper ores

⊗ Low recovery rate

The main reason for this phenomenon lies in the complexity of the mineral occurrence state. For example, sulfide copper ores often coexist densely with pyrite, making it difficult to achieve individual liberation through conventional crushing. Furthermore, oxide copper ores easily form passivation films on their surfaces, hindering copper ion dissolution. In addition, some ores contain a large amount of easily mud-forming minerals, which not only interfere with the stability of flotation froth but also adsorb beneficiation reagents, further reducing copper recovery efficiency.

⊗High Energy Consumption and Cost

To achieve sufficient sulfide liberation or effective exposure of oxides, the ore typically needs to be ground to the micron level, which can require 30% more power from ball mills than for conventional copper ores. Secondly, due to the poor surface activity of the minerals, the flotation process requires large amounts of expensive activators, while leaching of oxide ores relies on high doses of leaching agents. Even more challenging is that organic carbon in carbonaceous copper ores preferentially adsorbs reagents, requiring the addition of additional inhibitors.

⊗Environmental Pollution Risks

The acidic wastewater generated from sulfide oxidation contains heavy metals such as arsenic and cadmium. Traditional lime neutralization methods create toxic sludge that is difficult to store, polluting surrounding soil and water sources. High-pressure acid leaching processes produce highly acidic wastewater; incomplete neutralization will severely threaten ecosystems and incur high treatment costs. Residual organic reagents in flotation tailings may continue to release toxicity, while incomplete cyanide degradation poses long-term ecological risks. Increasingly stringent environmental regulations are forcing the industry to seek cleaner solutions.

2025 Refractory Copper Ore Processing Solutions

1. Intelligent Controlled Flotation Process

For the complex mineral composition of refractory copper ores, one of the mainstream solutions in 2025 is the intelligent controlled flotation process. This copper ore flotation technology, through the integration of a PLC automatic control module, monitors the feed concentration, reagent dosage, and flotation froth status in real time, dynamically adjusting process parameters to control the separation purity fluctuation range within ±0.3%. It is particularly suitable for refractory ores with high mud content and fine mineral particle size.

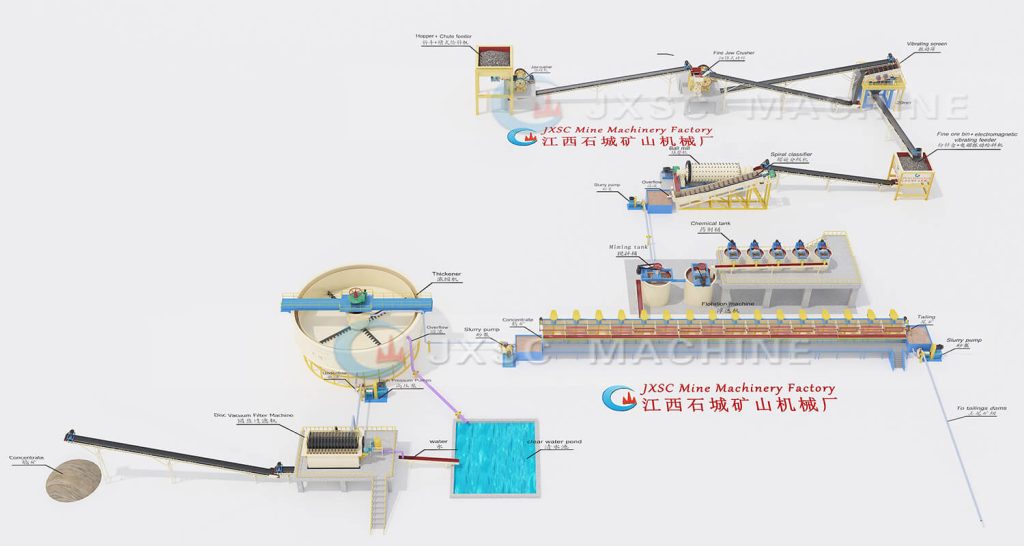

2. Gravity-Flotation Combined Separation Technology

The gravity-flotation combined process addresses the low recovery rate of coarse-grained minerals in single flotation by using multi-stage separation modules in synergistic operation. This technology first pre-treats coarse-grained ore with gravity separation equipment (such as spiral chutes) to remove low-density gangue, then performs flotation to refine the enriched minerals. Simultaneously, this process supports the separation of five types of copper ore varieties, including oxidized and sulfide ores, with a compatibility coverage exceeding 95%, making it particularly suitable for difficult-to-process complex copper ores with associated precious metals.

3. Chemical Leaching-Extraction Integrated Technology

For low-grade oxidized copper ores, such as malachite and azurite, chemical copper ores leaching-extraction technology has become a key technology for overcoming difficulties by 2025. This method dissolves copper ions in the ore through sulfuric acid heap leaching or ammonia leaching systems, followed by solvent extraction to separate copper from impurities, and finally obtains electro-deposited copper through electrolytic deposition. The leachate is used to directly extract cathode copper through extraction-electrowinning, with a comprehensive recovery rate of over 90%, making it particularly suitable for tailings reprocessing or in-situ leaching.

4. Customized Refractory Copper Ores Solutions

The combined refractory copper ores solutions leverages the advantages of multiple methods to process complex ores, significantly improving overall efficiency. For extremely complex copper ores (such as copper-lead-zinc co-existing ores), a “flotation-chemical beneficiation” synergistic process is employed. First, a mixed concentrate is obtained through flotation, then impurities are separated by leaching (acid/alkali), precipitation, or ion exchange based on mineral characteristics. For processing difficult-to-beneficiate oxide copper ores with high silica and high calcium-magnesium content, copper recovery can be achieved through a three-step process of “roasting-segregation-flotation.” A combined flotation-magnetic separation process can also be used: first, copper sulfide is recovered by flotation, then magnetic separation removes magnetic iron impurities, improving concentrate quality.

Conclusion

Refractory copper ores include sulfide copper, oxide copper, and mixed ores. It is facing three major challenges: the low recovery rate of traditional flotation/leaching methods, the high energy consumption and cost of ultrafine grinding, and the environmental risks of arsenic and sulfur-containing harmful elements. JXSC offers solutions encompassing gravity separation, flotation, leaching, and electrolytic extraction, balancing technological breakthroughs with sustainability. These solutions should be flexibly combined and applied according to the specific characteristics of the ore. Looking for customized mineral processing equipment? Contact our expert team for efficient and sustainable mineral processing technology support!