100TPH Alluvial Chrome Wash Process Plant In Zimbabwe

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

1. Raw ore: alluvial chrome ore, the chrome grade in the raw material is 17-23%, and it also contains magnetite; it is mainly soil and clay, mixed with a small amount of stones, gravel and leaves and branches.

2. Capacity: 100TPH

3. Feed size: >70mm

4. Output size: 0-2mm

5. Location: Zimbabwe

Process

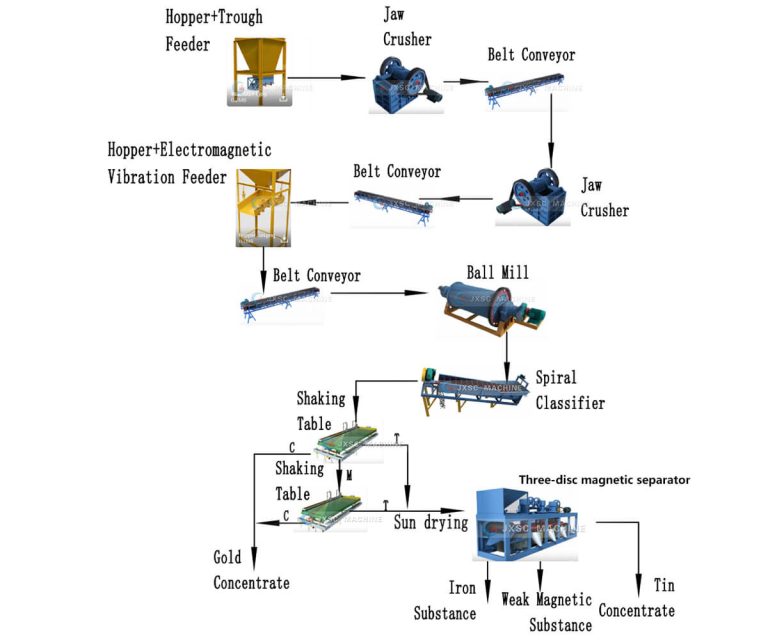

Feeding – Washing – gravity separation – magnetic separation – dewatering

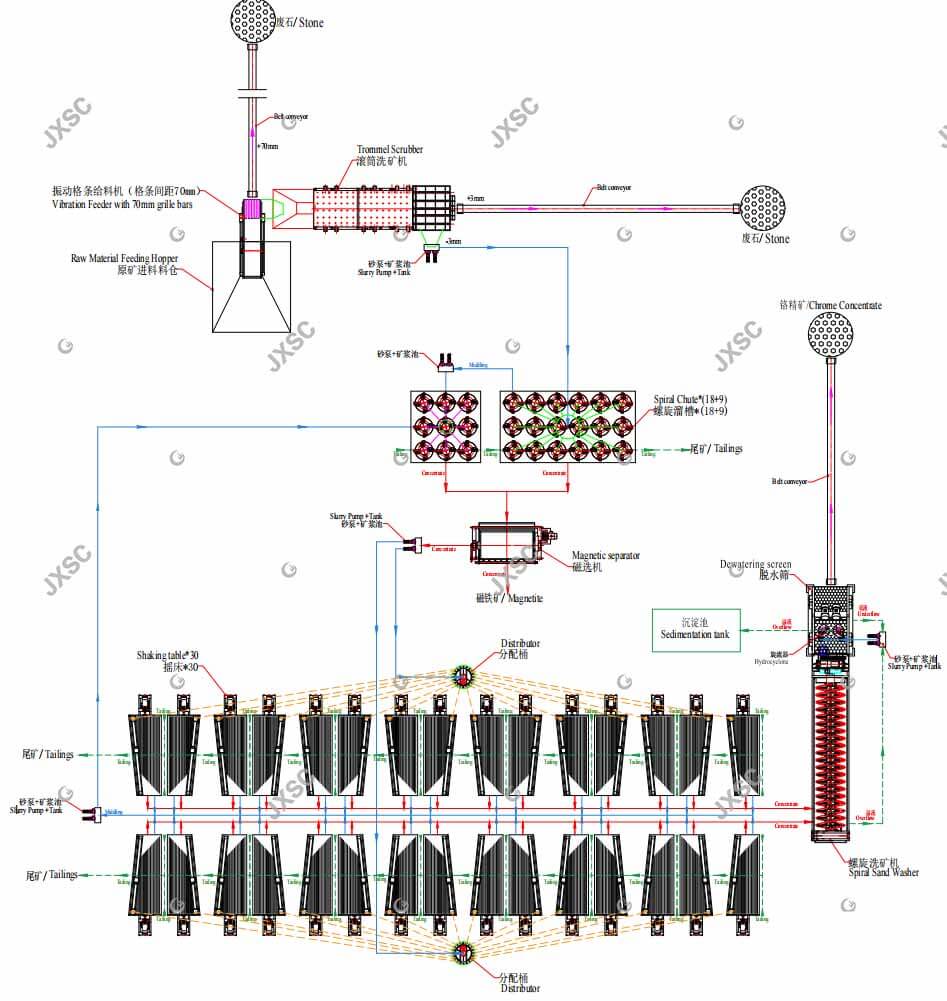

process flow

Ore information: Alluvial chrome ore contains various impurities, and the chromium grade in the raw material is 17-23%.

Customer requirements:

- The required feeding capacity of the plant is 100 tons per hour;

- The plant runs 20 hours a day, and the daily concentrate output must reach 500 tons;

- The raw ore also contains magnetite, so the iron content needs to be reduced to increase the chrome concentrate ratio;

- After beneficiation, the required concentrate target grade needs to reach 48-50%.

100TPH Alluvial Chrome Wash Process Plant flow

Based on the above ore information and customer requirements, JXSC professional engineers customized a complete set of 100TPH alluvial chrome wash process plants, flow charts, equipment, and accessories for this project. It mainly includes feeding, washing, gravity separation, magnetic separation, and dehydration processes. The following is the detailed process:

- The excavator unloads the raw materials into the feed hopper, which is then evenly fed into the drum washer through the vibrating feeder. The vibrating feeder has a 70mm gap grid to facilitate the removal of large stones above 70mm.

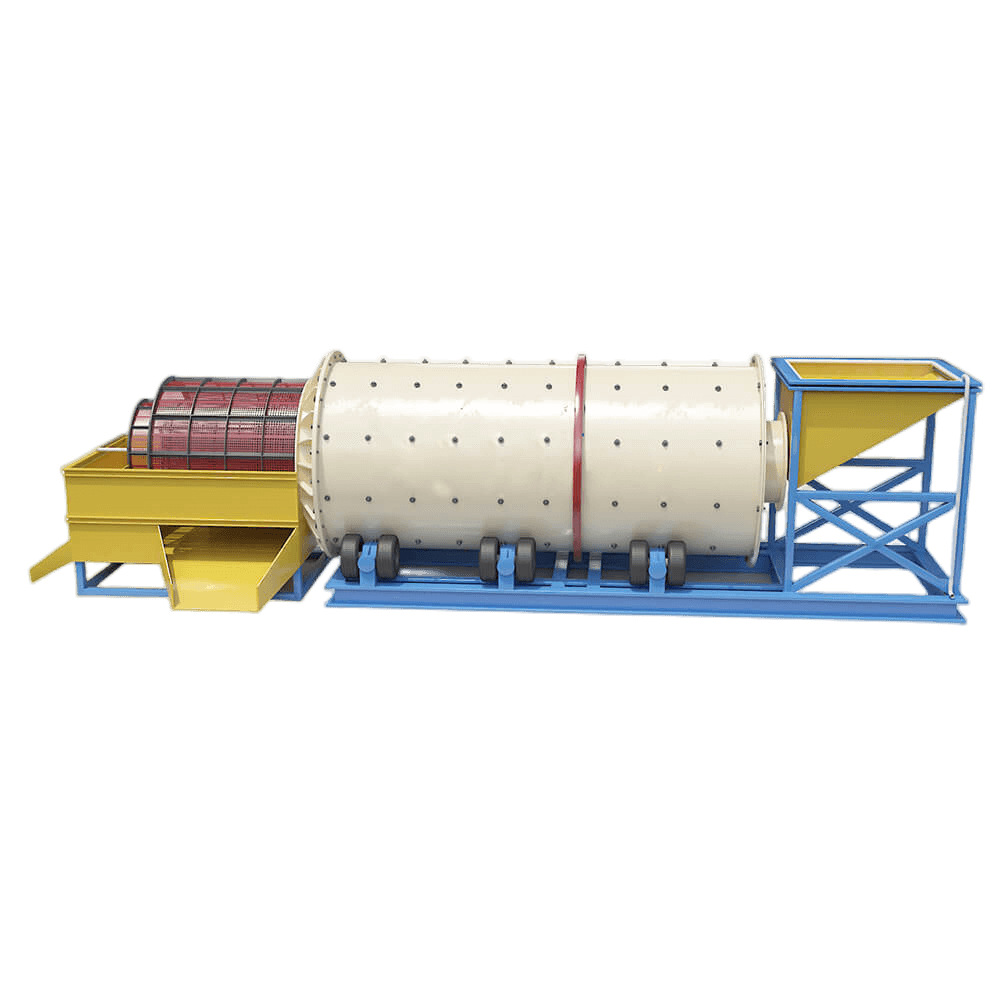

- The trommel scrubber has two layers of PU screens with mesh sizes of 2mm and 20mm. The 20mm PU screen protects the 2mm mesh. The trommel scrubber cleans the soil and clay on the surface of the raw materials and screens out waste materials above 2mm.

- After cleaning and screening by the trommel scrubber, materials smaller than 2mm are pumped into the rough spiral chute, totaling 18 sets. The middlings are pumped to the second section of the selected spiral chute (9 sets) for further separation to improve the recovery rate. So, there are 27 sets of spiral separators

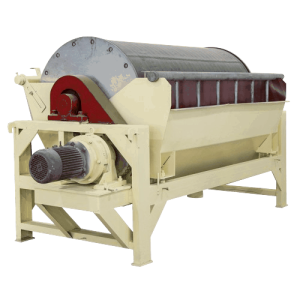

- The chrome concentrate produced by the roughing spiral and the selected spiral enter the drum magnetic separator to reduce the iron content of some magnetite, thereby increasing the chrome concentrate ratio.

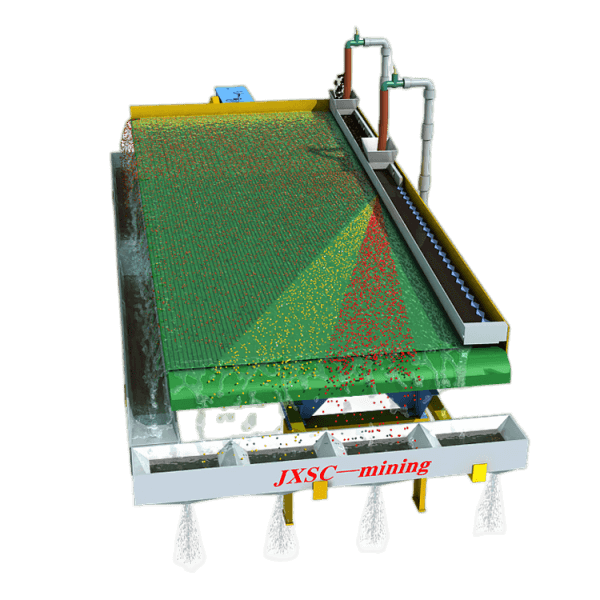

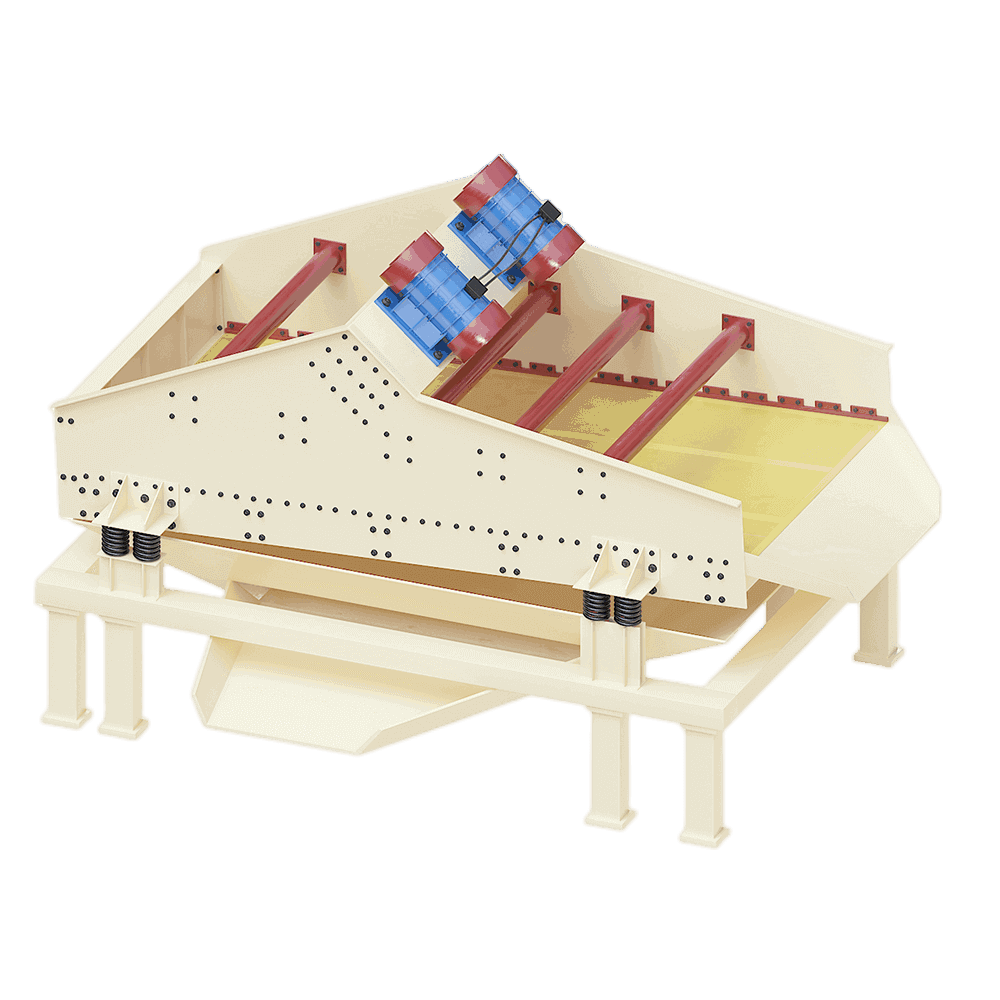

- The chrome concentrate, after sorting by the magnetic separator, is pumped to the shaking table, which has a total of 30 shaking tables. Every 15 shaking tables corresponds to a distribution tank. The slurry pump sends the chrome concentrate to the distribution tank, and then the slurry is distributed to each shaking table. The middlings of all shaking tables are sent back to the selected spiral chute for separation again to improve the recovery rate. Among them, the tailings are sent to the sedimentation tank.

- All chrome concentrates produced by the shaking table are sent to the spiral sand washer to remove most of the water. Its underflow enters the dewatering screen for further dewatering, and the dewatered concentrate can be transported to the finished product pile by the belt conveyor. The overflow of the spiral sand washer and the pulp under the dewatering screen are returned to the hydrocyclone by the pump. The overflow of the hydrocyclone enters the sedimentation tank, and the underflow enters the dewatering screen, completing the entire dewatering system.

This complete chrome wash process plant has a concentrate recovery efficiency of up to 48-50%, with good economic benefits. Different mineral information and requirements are suitable for different beneficiation processes. JXSC will customize the chrome wash plant and equipment according to the mineral characteristics and customer needs. Contact us for more chrome wash process details!

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.