15TPH Chrome Wash Recovery Plant In South Africa

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

- Raw ore: chrome ore with contain less sticky clay

- Capacity: 15TPH (15 tons/per hour)

- Feed size: >100mm

- Output size: 0-2mm

- Location: South Africa

Process

Washing – Gravity Separation (spiral chutes, shaking tables)

process flow

15TPH Chrome Wash recovery Plant

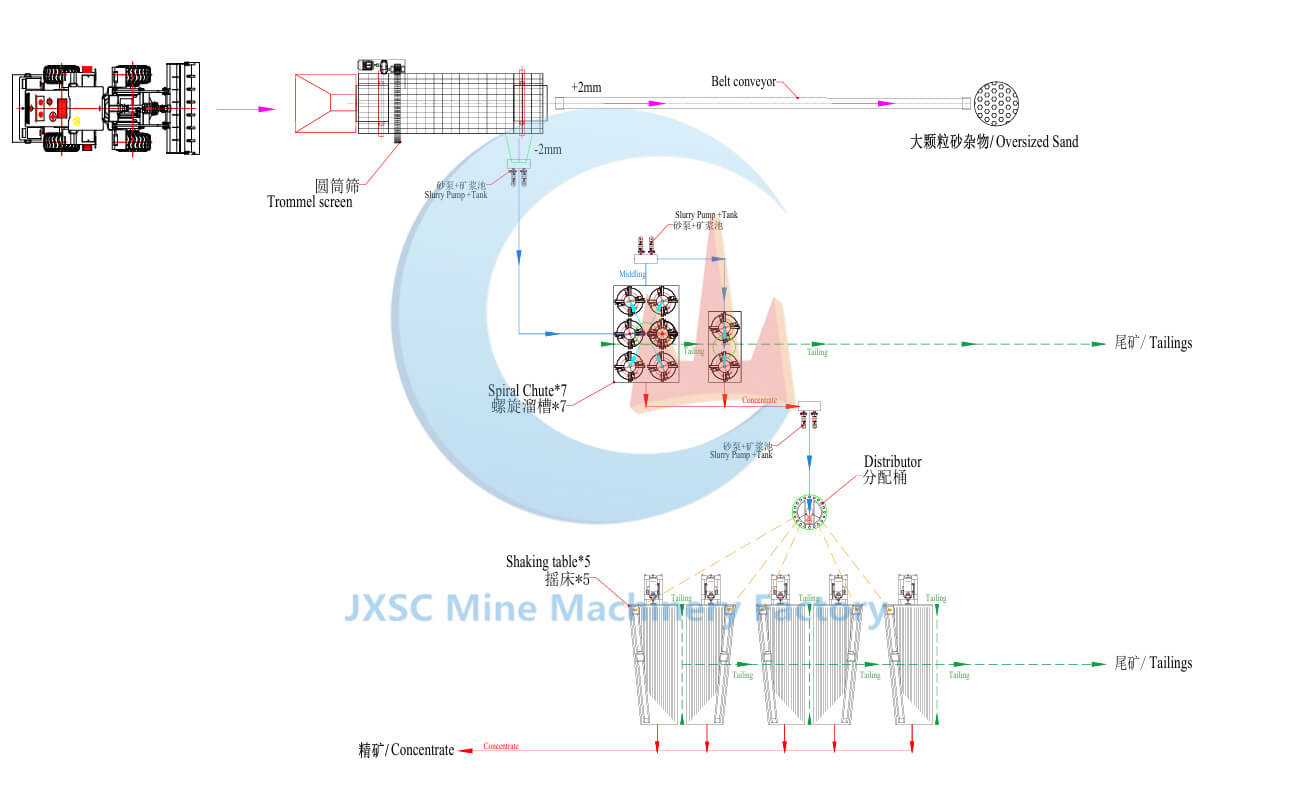

According to the customer’s requirements and mineral information, JXSC has carefully designed and optimized the chrome ore processing flow. The process is relatively simple, it mainly includes washing and gravity separation, ensuring that every step from cleaning to the final product can achieve the best beneficiation effect. The following is the specific chrome wash recovery plant process:

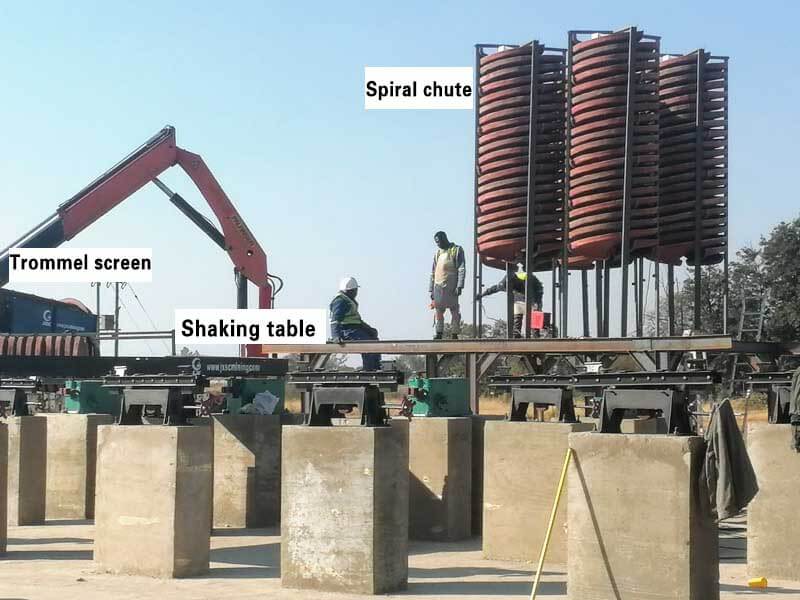

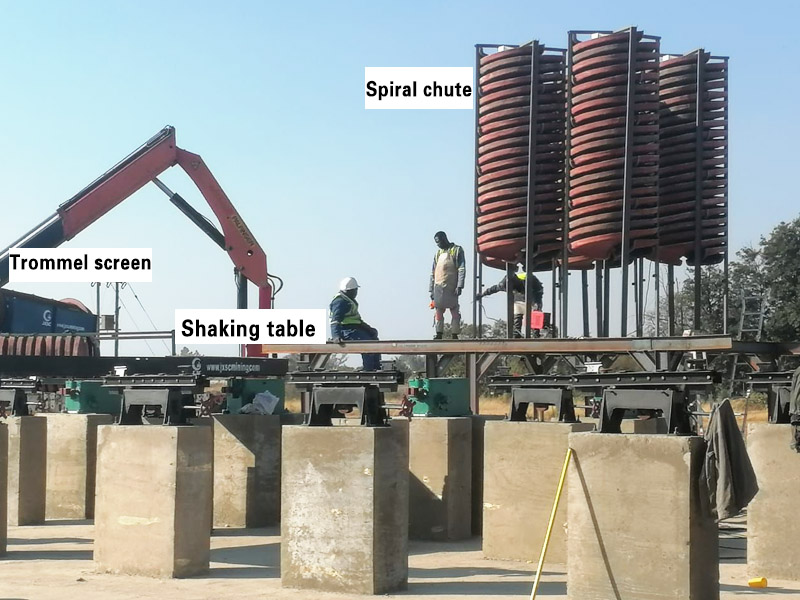

1. The excavator or truck feeds the raw ore into the feed port of the drum screen, and then the trommel screen screens out the 0-2mm and >2mm materials. The materials larger than 2mm are sent to the waste pile by the belt conveyor. The 0-2mm materials are sent to the mud pool.

2. The 0-2mm materials are sent to the first-stage spiral chute group for sorting with a slurry pump to separate the chrome concentrate, middlings, and tailings.

3. The middlings are transported from the first-stage spiral chute group to the second-stage spiral chute group by a slurry pump for further processing, and the middlings in the second-stage spiral chute will be pumped to the third-stage spiral chute, so that more chrome concentrate can be recovered. Then, all the tailings enter the tailings pool.

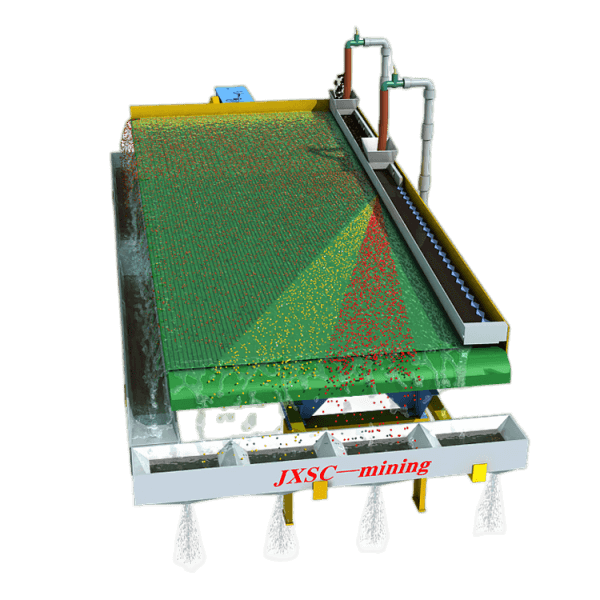

4. Then, the concentrates of the two-stage spiral chute group are sent to the concentrate pool, and then sent to the distribution barrel by a slurry pump for uniform mixing. Finally, it is sent to five sets shaking tables for concentration. Finally, higher grade and quality concentrates can be extracted and recovered.

Process Site

15TPH Chrome Wash recovery Plant Site

This set of chrome wash recovery plant equipment is not only economically efficient and has good recovery effect, but also has no environmental pollution. Different mineral information and requirements are suitable for different mineral processing methods. JXSC supports customizing energy-saving and efficient chrome wash plants and equipment according to mineral characteristics and customer needs to ensure maximum recovery of chrome-containing minerals.

Not sure how to configure your chrome wash plant equipment? – Contact us for more process and equipment details!

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.