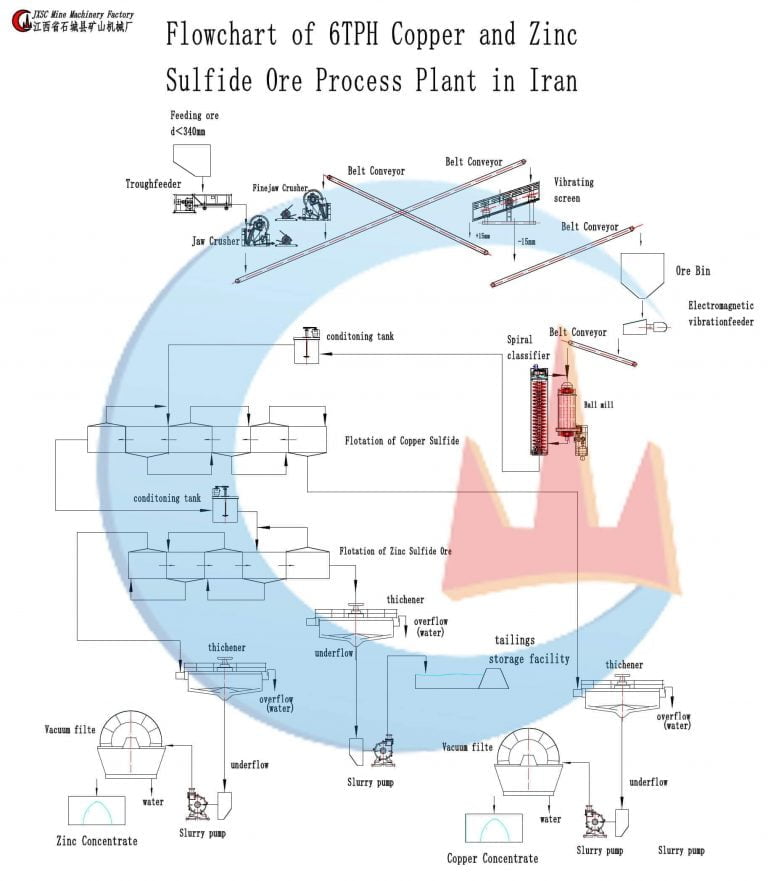

6TPH Copper & Zinc Sulfide Ore Process Plant in Iran

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience!

minerals

Copper and Zinc Sulfur Ore, copper grade1.5-3%, zinc 10-30%

capacity

6TPH in Iran

feed size

0-340mm

Customer's request

Copper grade to 70%, zinc grade up to 68%

process flow

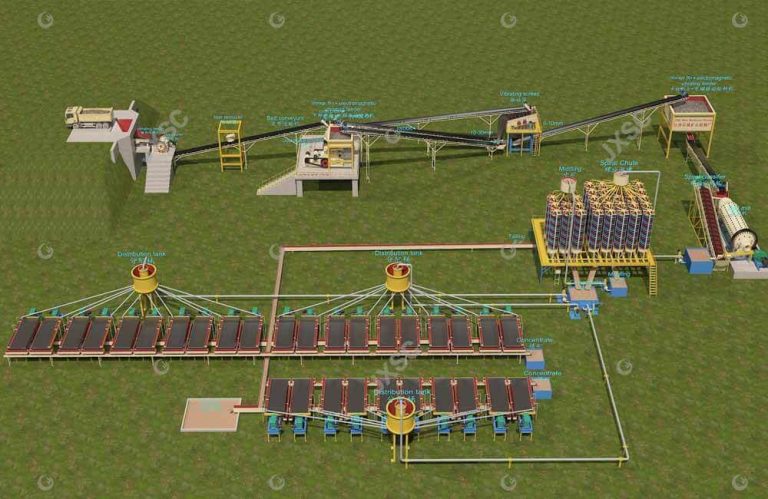

6TPH Copper & Zinc Sulfide Ore Process Plant

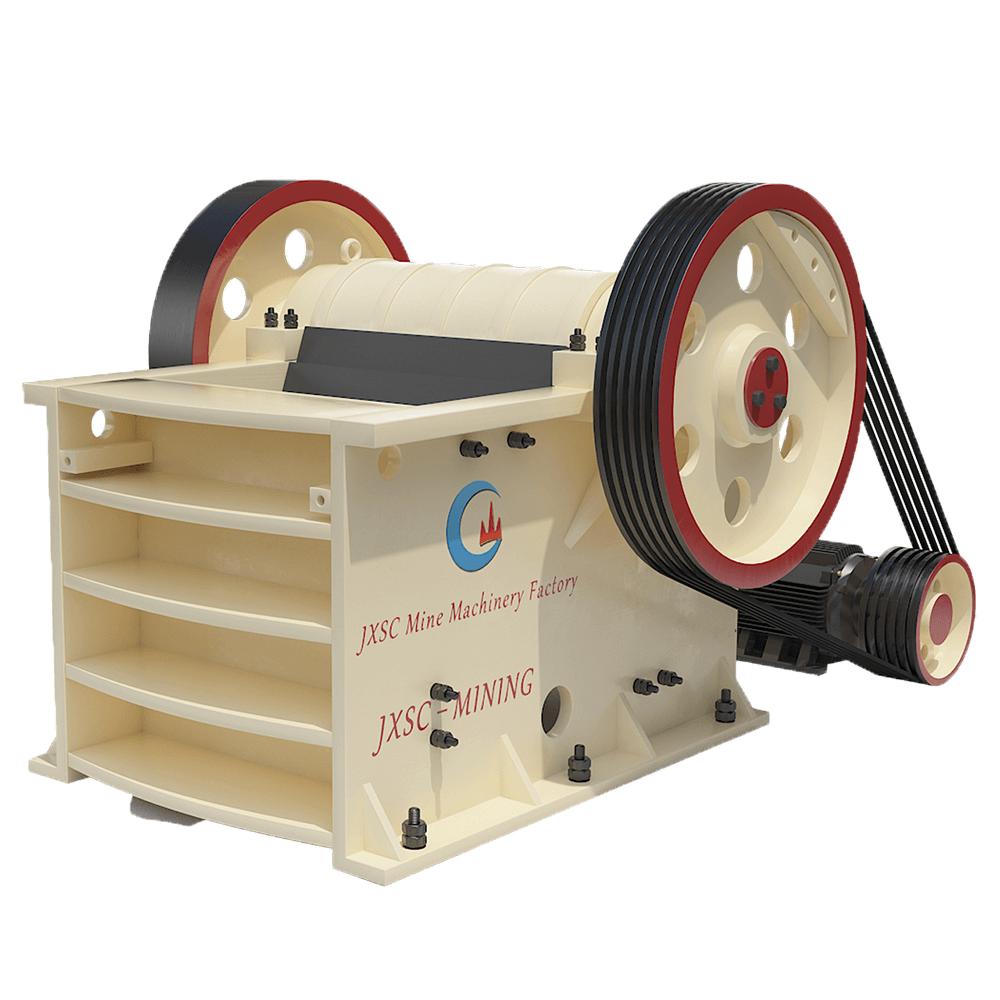

1. Crushing & Screening: jaw crusher, vibrating screen

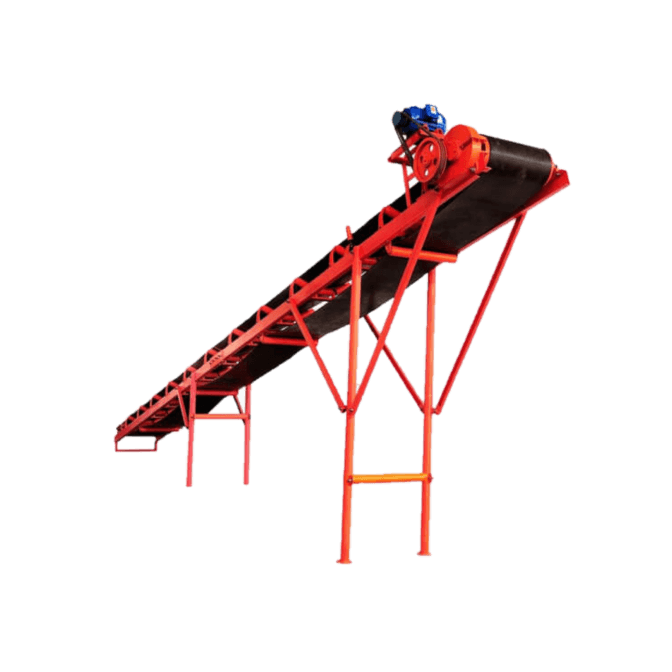

Trough feeder is for feeding raw material to primary jaw crusher stably and evenly, can feed 0-340mm stones, then primary jaw crusher crushes the big rock to a smaller size, about 15mm. The materials pass through the belt conveyor belt vibrating screen to screen out two kinds of materials of different sizes, which are larger than 15mm and 0-15mm. The material smaller than 15mm enters the fine jaw crusher for the second crushing and is crushed below 15mm.

2. Grinding stage: ball mill, spiral classifier

The 0-15mm material will firstly go to a storage bin before feeding to the ball mill, then feed the 0-15mm material by electromagnetic vibration feeder to the ball mill through belt conveyor. The ball mill is for grinding material to small fine powder because the flotation process needs 200mesh material, and works together with a spiral classifier to reach 200mesh output from the overflow of classifier.

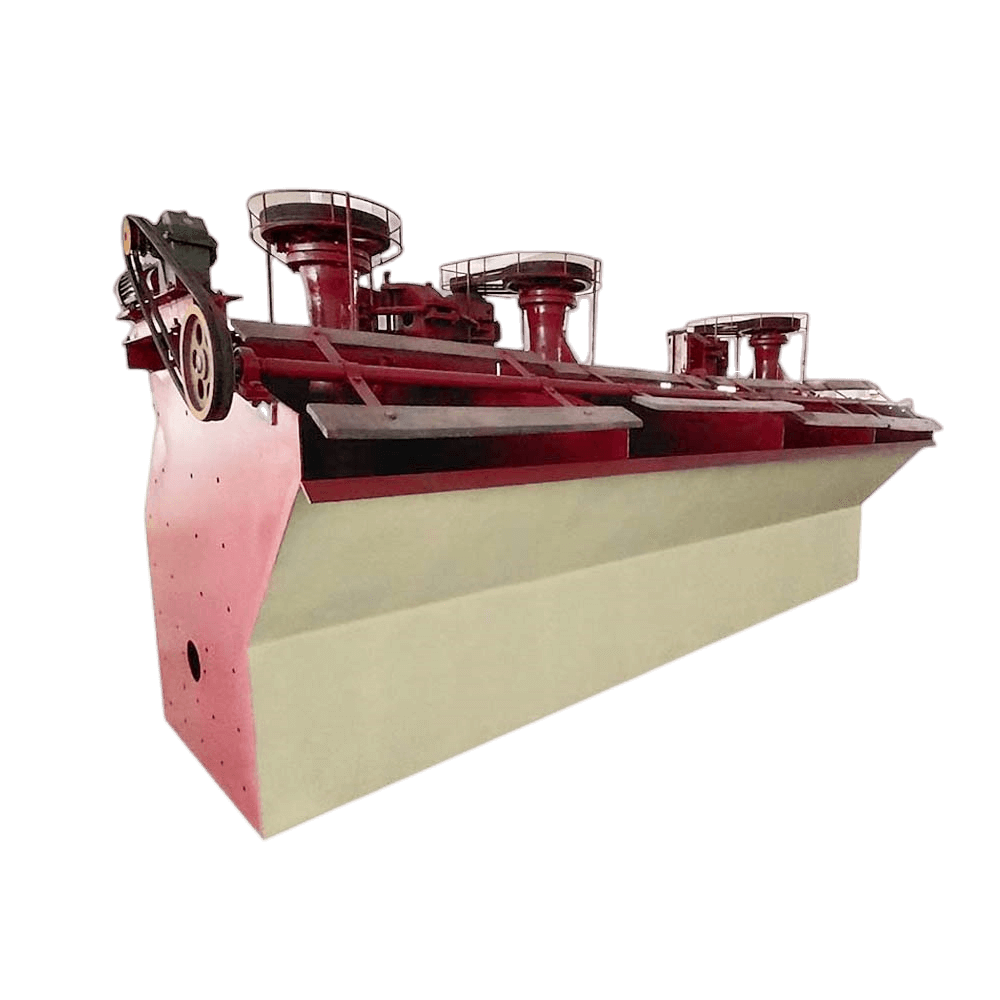

3. Flotation separation: flotation machine

The 200mesh slurry will be firstly sent to the conditioning tank, and to make sure material is mixed completely, then go to flotation machines, need to add different chemicals in flotation machine to separate out different minerals.

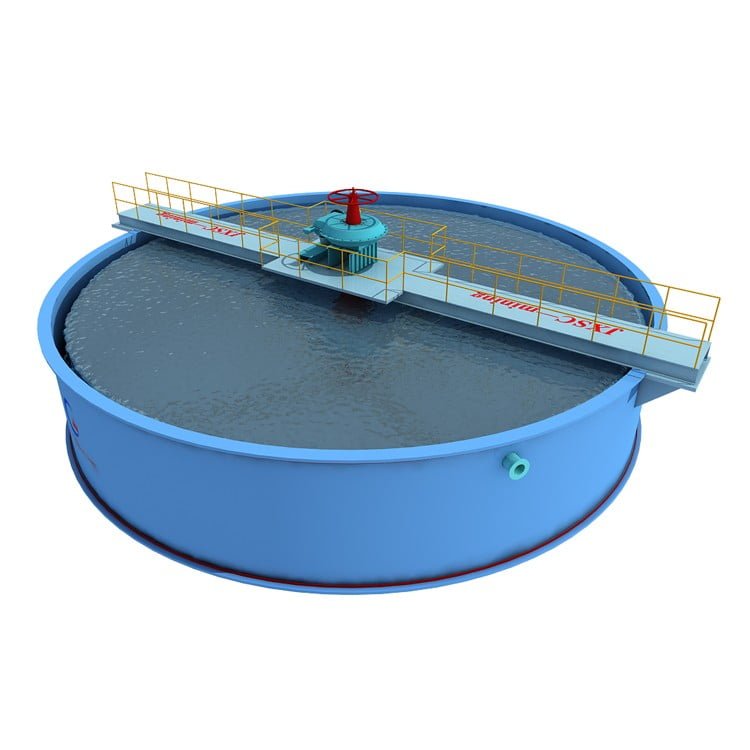

4. Concentrate ore filtering system: thickener, disc vacuum filter machine, slurry pump

After getting the minerals to concentrate ore from the flotation system, for the high-grade copper, lead minerals by using the thickener to concentrate, make higher density, then by slurry pump send to disc vacuum filter to filter water, and get more dry concentrate minerals. Then can dry in the sun or by drying machine to get complete dry minerals to concentrate ore.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.