High-Efficiency Chrome Wash Plant

One-stop chrome processing solutions help you improve concentrate recovery rates and yields.

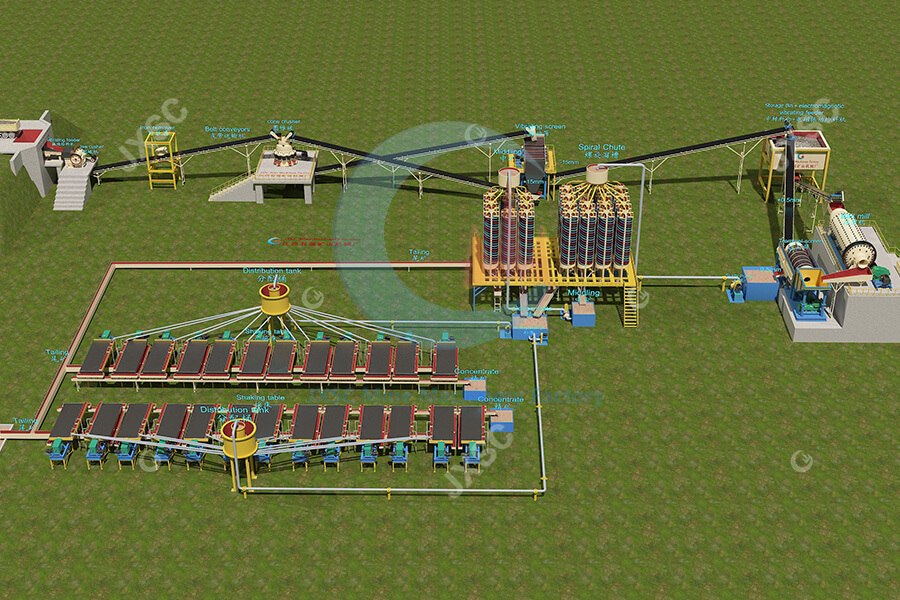

A chrome wash plant is an intelligent mineral processing system that uses processes such as crushing, washing, screening, and gravity, magnetic separation to physically separate raw ore. Its core objective is to improve the grade of Cr₂O₃, extract chromium ores, purify them, and achieve eco-friendly tailings treatment to concentrate. Maximize your chrome recovery rate with JXSC’s state-of-the-art washing process & equipment designed for efficiency, sustainability, and high-yield plants.

- 95-98%+ Recovery Rate

- Low Water Consumption

- Machines 100% Factory Price

- Small-scale Modular Designs

What is Chrome Wash Plant?

A chrome wash plant is specialized processing equipment designed to extract and recover chromite minerals from raw ore. These plants use various physical separation techniques to upgrade the concentrate grade by removing impurities and increasing chromite content. Our modular systems are adaptable to various operational requirements.

Key Process of Our Chrome Wash Plants

- Feed Preparation System – Efficient scrubbing and screening of raw material.

- Gravity Separation Units – Spiral separators, jigs, and shaking tables for maximum recovery.

- Water Management System – Advanced recycling for minimal water consumption.

- Product Handling – Efficient dewatering and stockpiling systems.

Natural ore typically contains low Cr₂O₃ content (20%-40%) and a large number of impurities (such as silicon, magnesium, calcium, etc.), so it needs to be purified through mineral processing to meet the market demand for high-grade chromium concentrate (Cr₂O₃≥48%). JXSC wash plants can beneficiate various types of chrome ore, including laterite, alluvial, and hard rock deposits.

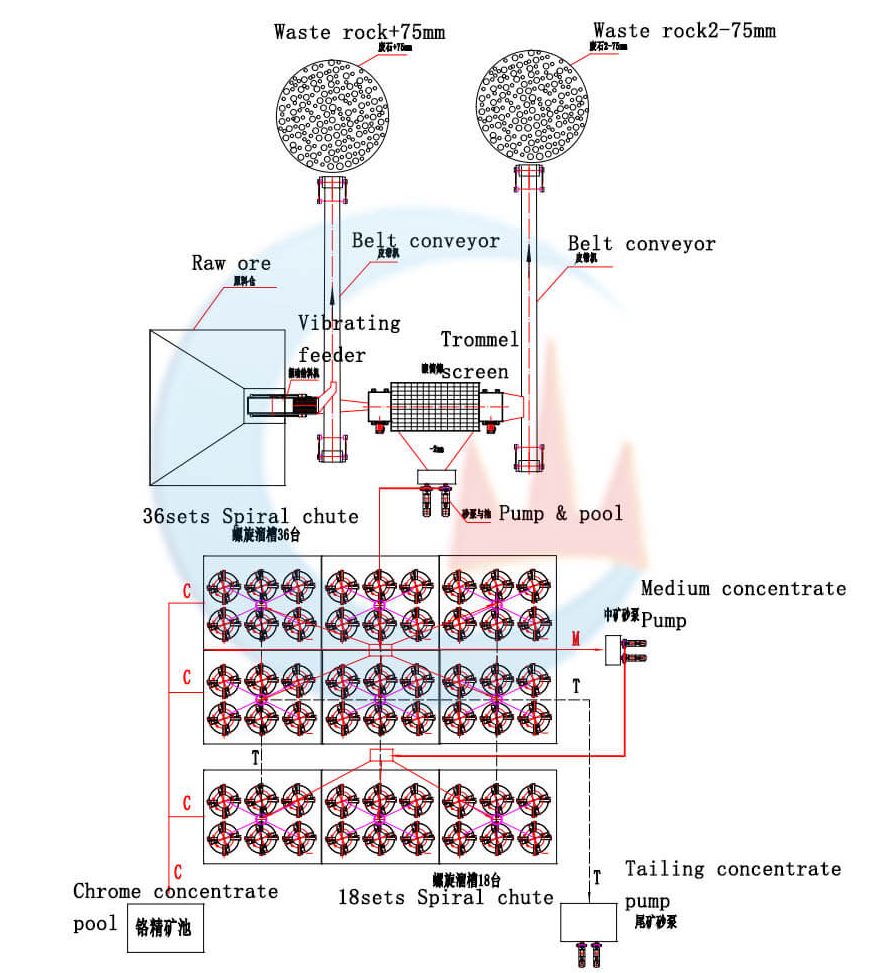

Chrome Wash Plant Process Flow

JXSC chrome wash plants incorporate the latest advancements in mineral processing technology to deliver superior results. Our comprehensive mining washing system ensures maximum chrome recovery through these optimized stages:

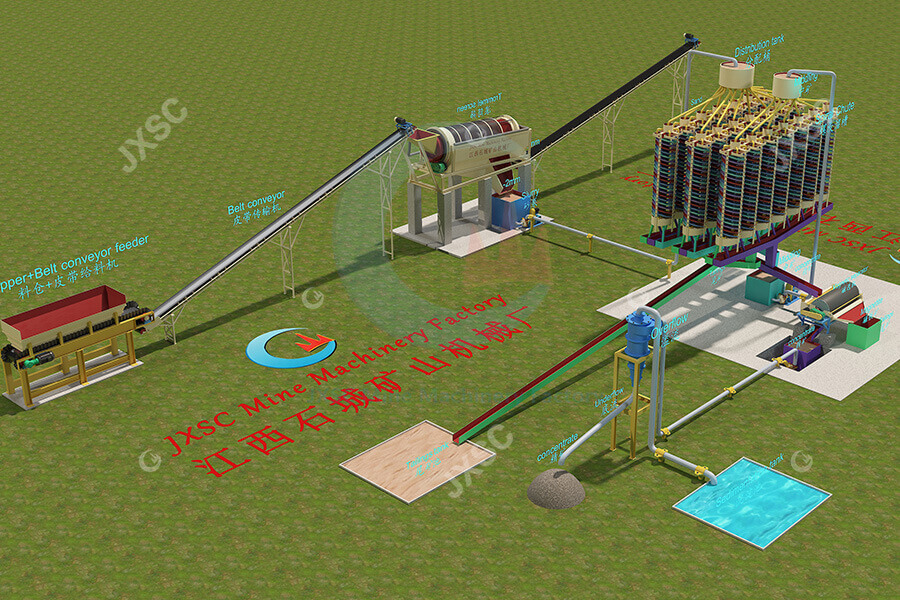

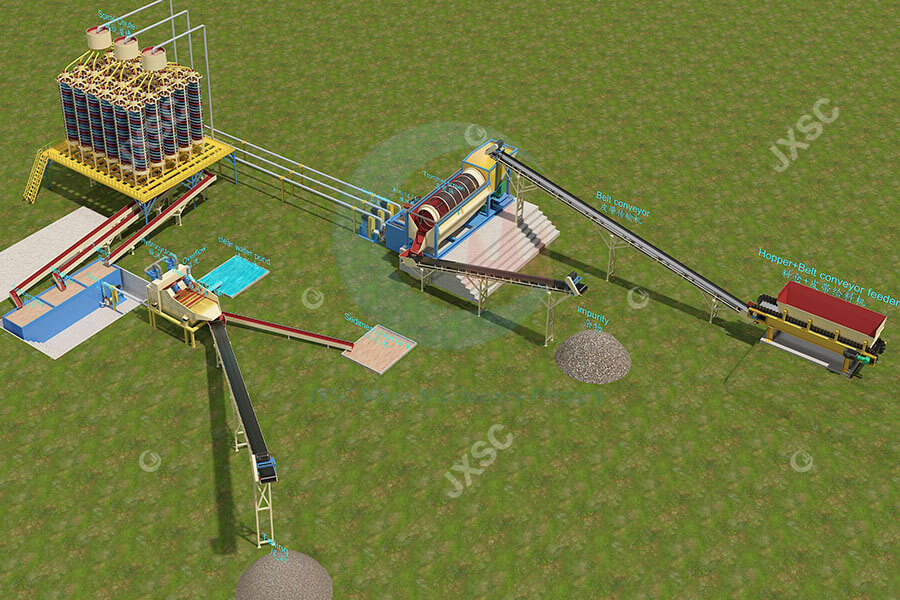

Raw ore is fed into the plant and undergoes initial screening to remove oversize material and ensure consistent feed size for optimal processing.

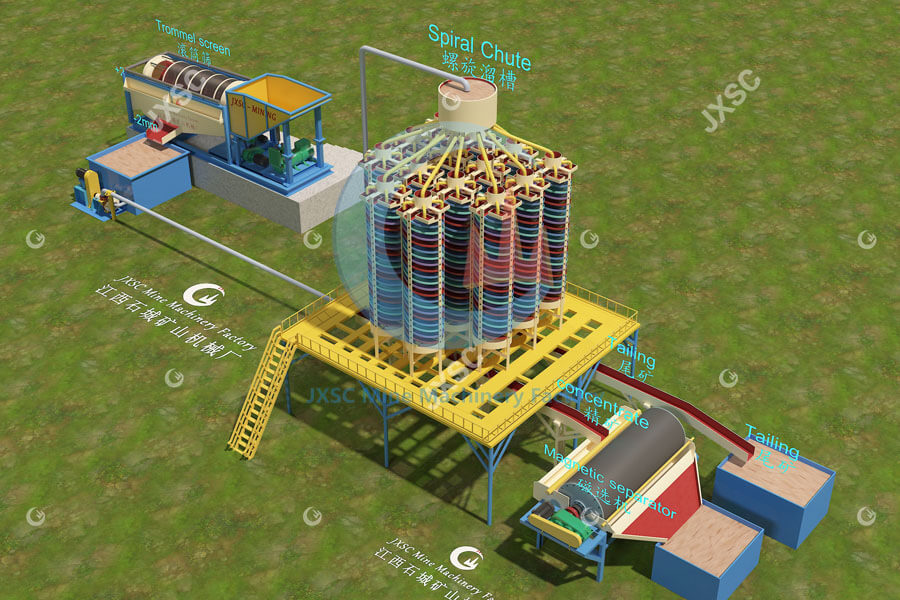

Rotary scrubbers/ trommel screen break down clay and other binding materials, liberating chrome particles for efficient washing & separation.

Vibrating screens separate material into different size fractions for targeted processing based on particle characteristics.

Spiral chutes and jig concentrators separate chrome from gangue material based on specific gravity differences.

Specialized shaking tables and magnetic separators recover fine chrome particles missed in primary separation.

Thickener + filter press system achieves 85% water recovery; Dry stack tailings processing meets environmental standards.

chrome wash plant Solutions

JXSC provides alluvial/ rock, laterite chrome beneficiation solutions, with small to large processing capacity can be designed according to your ore information and needs. All can be configured with standard mining equipment that offers low cost and high recovery rates.

Ore → Crushing (optional) → Screening → Washing → Gravity Separation → Dewatering → Finished Product

1. Alluvial/Placer Chrome Washing Plant Solution

(Primarily Desliming and Gravity Separation)

- Process: Ore → Feeding → Trommel scrubber/Spiral washer (desliming) → Vibrating screen (classification) → Jig concentrator (roughing separation) → Spiral chute/shaking table (Concentration) → Magnetic separation upgrading (Optional) → Thickening and dehydration → concentrate.

2. Rock-Type Chrome Processing Solution

(Crushing + Grinding + Sorting)

- Process: Ore→ Feeding → Jaw crusher (coarse crushing) → Cone crusher/Hammer crusher (fine crushing) → Ball mill (with spiral classifier) → Trommel screen/ vibrating screen (washing & classification) → Shaking table/spiral chute (sorting) → Magnetic separation (purification) → Concentration and filter press → Drying.

Whether it is the efficient desludging of small alluvial sand mines or the deep processing of large complex rock mines, JXSC can help customers achieve efficient and environmentally friendly chrome ore purification goals through a full chain of services, including “ore testing – process design – equipment implementation – capacity optimization“.

Core Equipment for chrome wash plant

With over 40 years of experience in chrome mineral processing equipment manufacturing, including chrome washers, spiral chutes, and shaker tables, etc. JXSC offers the industry’s best-selling products at the most affordable prices.

1. Crushing & Grinding (optional)

- Jaw crusher: Used for coarse crushing of large chromium ore.

- Cone crusher/impact crusher/hammer crusher: Provides secondary crushing, improving subsequent ore washing efficiency.

- Double Roller Crusher: Finely crushes chromite to a size suitable for washing.

- Ball mill: Rock-type chromium ore needs to be ground to a fineness of -200 mesh 60% to provide qualified particle size for subsequent sorting.

2. Washing Equipment

- Spiral washer: Removes clay and surface impurities, suitable for ores with medium adhesion.

- Rotary scrubber: Separates ore from clay through rotary friction, suitable for ores with high clay content.

- Trommel screen: Used for cleaning minerals containing very little slime impurities; coarse particle screening + flushing to reduce clogging.

- Trough washer: Uses high-pressure water flow to remove stubborn impurities.

3. Screening Equipment

Vibrating screen and trommel screen: Classify by particle size (e.g., 0-5mm, 5-30mm, and above 30mm) and complement the washing process.

4. Separation Equipment (optional)

- Gravity separation-Jig separators, spiral chute and shaker tables: Separate chromite from gangue minerals (e.g., serpentine) to improve grade.

- Magnetic separators: Utilize the weak magnetic properties of chromite to remove iron-containing impurities further and improve the Cr/Fe ratio (suitable for applications requiring high grade).

- Flotation cells (auxiliary): Used for some low-grade or complex ores, they use reagents to adjust the mineral surface properties and separate gangue minerals.

5. Dewatering Equipment

Dewatering screens, thickener, and plate filter press: Reduce the moisture content of cleaned ore, making it easier to transport.

6. Auxiliary Equipment

Feeders (vibrating/plate type), conveyors (belt/screw), and slurry handling systems (thickening tanks and filter presses).

JXSC supplies various chrome processing solutions based on the ore type (alluvial/placer/rock ore/laterite ore), impurity characteristics, processing scale, processing goals (grade improvement, impurity removal), budget, and other conditions!

Chrome Plant Successful cases

Ideal for African mines: ISO-certified modular chrome plants. High recovery & quick ROI, low setup cost, easy operation. Since 1985, 1000+ Successful Project Installations Worldwide. Free technical consultation!

Albania Rock Chrome Processing Project

Capacity: 5TPH

Our solution: crushing – grinding – gravity separation

Main Equipment: jaw crusher, ball mill, shaking tables

Results Achieved:

◼ 97.5% recovery rate ◼ payback period: 10 Months

South Africa Chrome Wash Plant Project

Capacity: 15TPH

Our solution: washing – gravity separation

Main Equipment: trommel screen, spiral chutes, shaking tables

Results Achieved:

◼ 98.2% recovery rate ◼ safety rating: A+

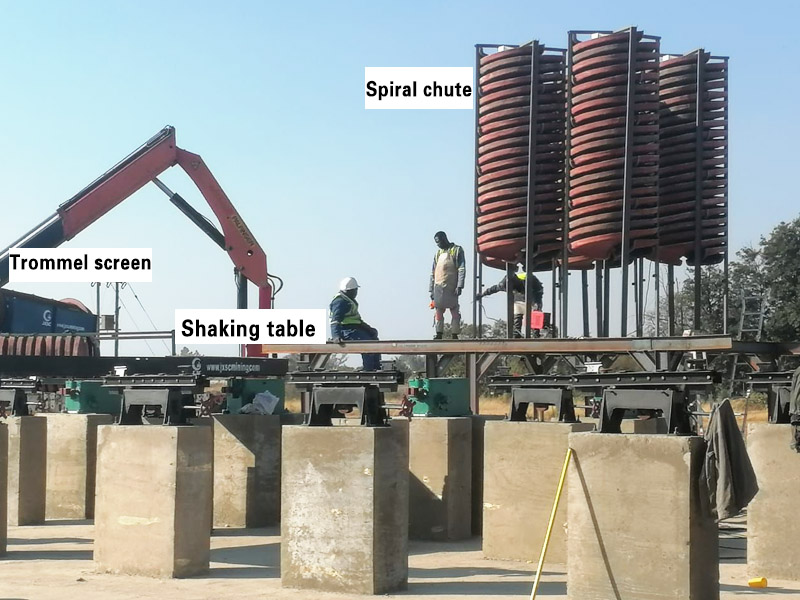

Zimbabwe Alluvial Chrome Wash Plant

Capacity: 100TPH

Input Grade: 17-23%

Our solution: washing – gravity & magnetic separation – dewatering

Main Equipment: trommel scrubber, spiral chutes, shaking tables

Results Achieved:

◼ 98.7% recovery rate ◼ concentrate grade: 48-50%

Why Choose JXSC Chrome Wash Plant?

Discover the advantages that make our chrome washing plant solutions the preferred choice for mining operations worldwide.

Our advanced gravity separation technology extracts 98% of the chrome from ore, directly improving your profitability.

The patented water recycling system reduces consumption by up to 70%, reducing costs and reducing environmental impact.

Quick installation and easy expansion capabilities, chrome spiral wash plant equipment 100% factory price.

100% quality assurance, heavy-duty corrosion-resistant materials ensure a long service life in harsh mining plants.

Advanced PLC systems monitor and adjust operations in real time, optimizing performance and reducing labor requirements.

30% lower energy usage than conventional plants, making our chrome washing plants a sustainable choice.

40+

Years Experience

100%

Factory Price

24/7 Support

Technical Service

Start Your Chrome Wash Plant Project

Contact our mineral processing experts for custom process and equipment list quote!