Precious Metal Extraction And Recovery System

Precious metal extraction and recovery system is mainly used to recover gold, silver, platinum, and rhodium from plating solutions, drag-out tanks, strip solutions, plating solutions, and iodine and iodide etching solutions. It can also be used to recover precious metals (gold, silver) from electronic waste stripping solutions, waste photographic developing solutions, electronic plating waste solutions, and gold/silver mines.

Precious Metal Extraction And Recovery System

Precious metal extraction and recovery system, also known as precious metal electrolytic recovery machine, gold and silver electrolytic recovery equipment. It mainly uses the principle of electrolysis to reduce metal ions in wastewater into metal blocks or powders. This equipment can effectively reduce silver ( gold or copper or nickel) ions directly into metal blocks through automatic intelligent control, and the purity reaches 99.8%. The precious metal extraction and recovery system requires no consumables and electrolytic accelerators, and the operating and maintenance costs are very low. This system is often used in conjunction with other electrolytic purification process for copper recovery.

Application range of metal Extraction system:

- Recover gold, silver, platinum, rhodium, and palladium from electroplating wastewater;

- Recover gold, silver, platinum, rhodium, and palladium from electroplating cleaning tank wastewater;

- Recover gold and silver from the circuit board gold etching solution;

- Extract gold and silver from electronic waste deplating solution leaching solution;

- Extract silver from the fixing solution;

- Extract gold or silver from the strip steel solution.

Process Of Precious Metal Extraction And Recovery System

Working principle

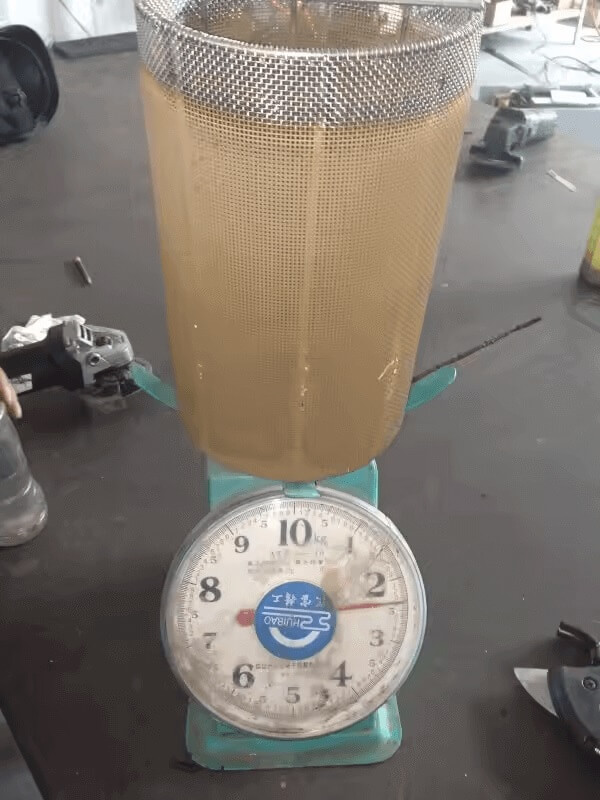

The precious metal extraction and recovery system mainly uses rotating cathode and high-frequency pulse intelligent electrolysis to recover gold or other precious metals. It does not require consumables or electrolytic accelerators and only consumes a small amount of electricity. It uses the principle of electrolytic adsorption to reduce liquid metal ions to metal, adsorb the metal on the cathode, strip off the metal residue, and re-refine and use it.

The machine can be installed online and offline:

- Online recycling: The recycling machine is installed next to the recycling tank behind the gold or silver plating cylinder. The water in the recycling tank is recycled to keep the metal content low. Less is brought to the next level of water tank, reducing the precious metal content discharged outside the workshop to achieve higher recovery.

- Offline recycling: The wastewater containing gold or silver generated on the production line is concentrated in a water storage tank, recycled by electrolysis in batches, and discharged to the sewage treatment pool after recycling.

Recycling effect

process features

1. No chemical reagents are added, only a small amount of electricity (150-250W) is used, and there is no worry about secondary pollution;

2. Small and compact, easy to operate, no special person is needed for supervision; full anti-corrosion design is adopted, and the machine has a long service life;

3. Large processing capacity, after combination, it can treat more than 6000-18000 liters of silver-containing wastewater per month, and the processing capacity of gold-containing wastewater is halved;

4. The recovery rate is more than 99%, and gold with a purity of more than 95-99.8% can be directly extracted;

5. The content of precious metals in the treated waste liquid: silver can be less than 5-20ppm, and gold can be less than 2-10ppm;

6. It can be directly installed on the production line, and the recovered high-purity precious metals can directly cover the anode. The precious metal blocks can be taken away immediately after separation.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.