Mining Thickening & Dewatering Equipment

Thickening & Dewatering Equipment Solution

JXSC is a supplier specializing in the research, development, production, and sales of mining equipment for thickening and dewatering. We are committed to providing efficient, energy-saving, and durable solutions to global mining customers.

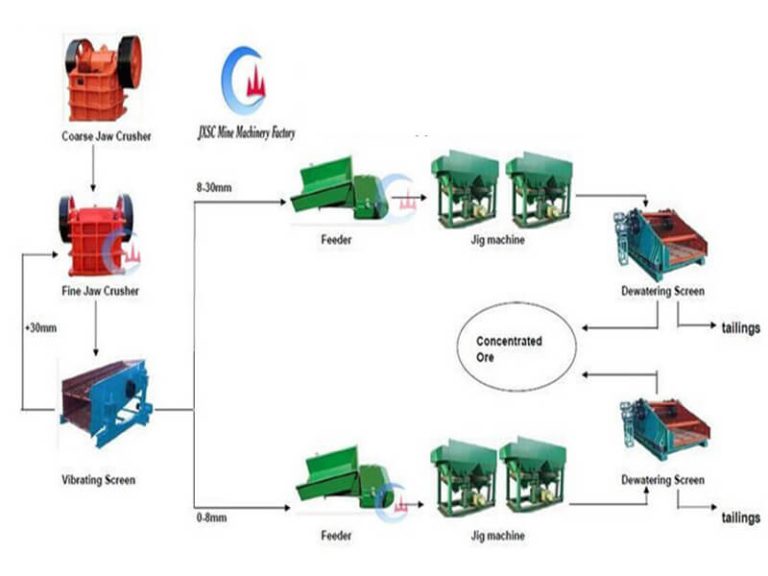

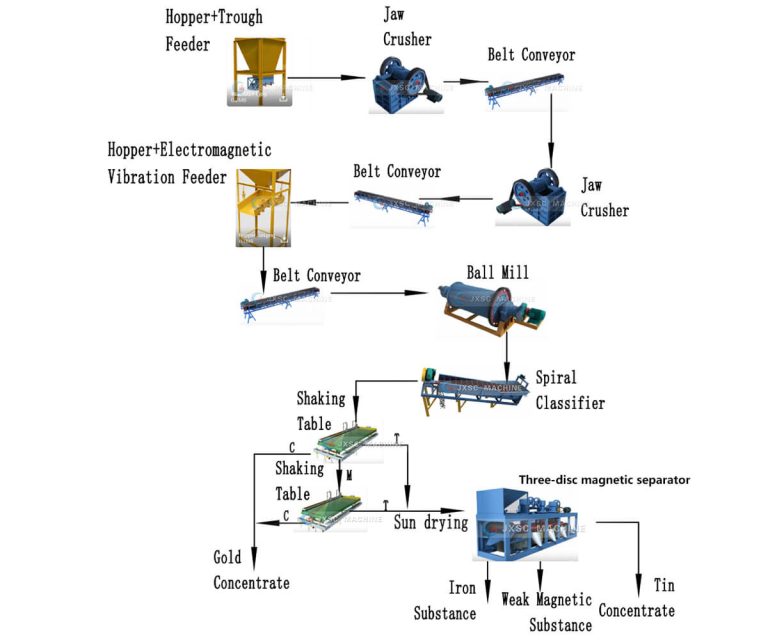

Mining thickeners and dehydrators are key components for solid-liquid separation in mineral processing. It’s widely used in the concentrating and dehydrating processes of metal ores and non-metallic ores, such as gold, silver, copper, iron, lithium, manganese, lead, zinc, and tin, etc. Our thickening and dehydrating machines primarily include dewatering screens, thickeners, plate and frame filter presses, vacuum disc filter presses, belt filter presses, and rotary dryers.

Mining Thickening & Dewatering Equipment for sale

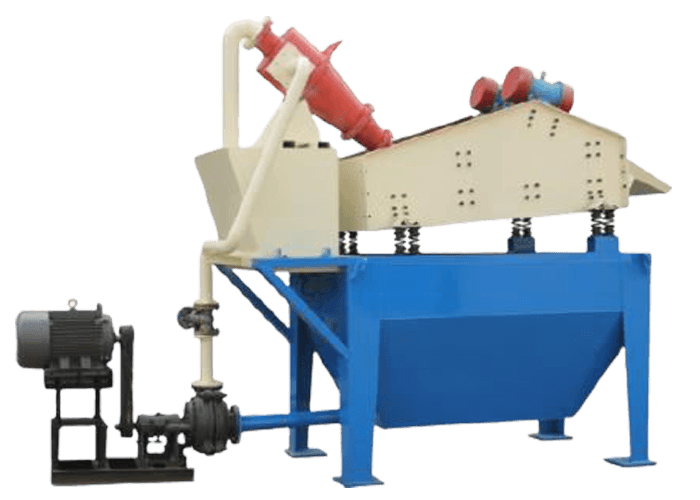

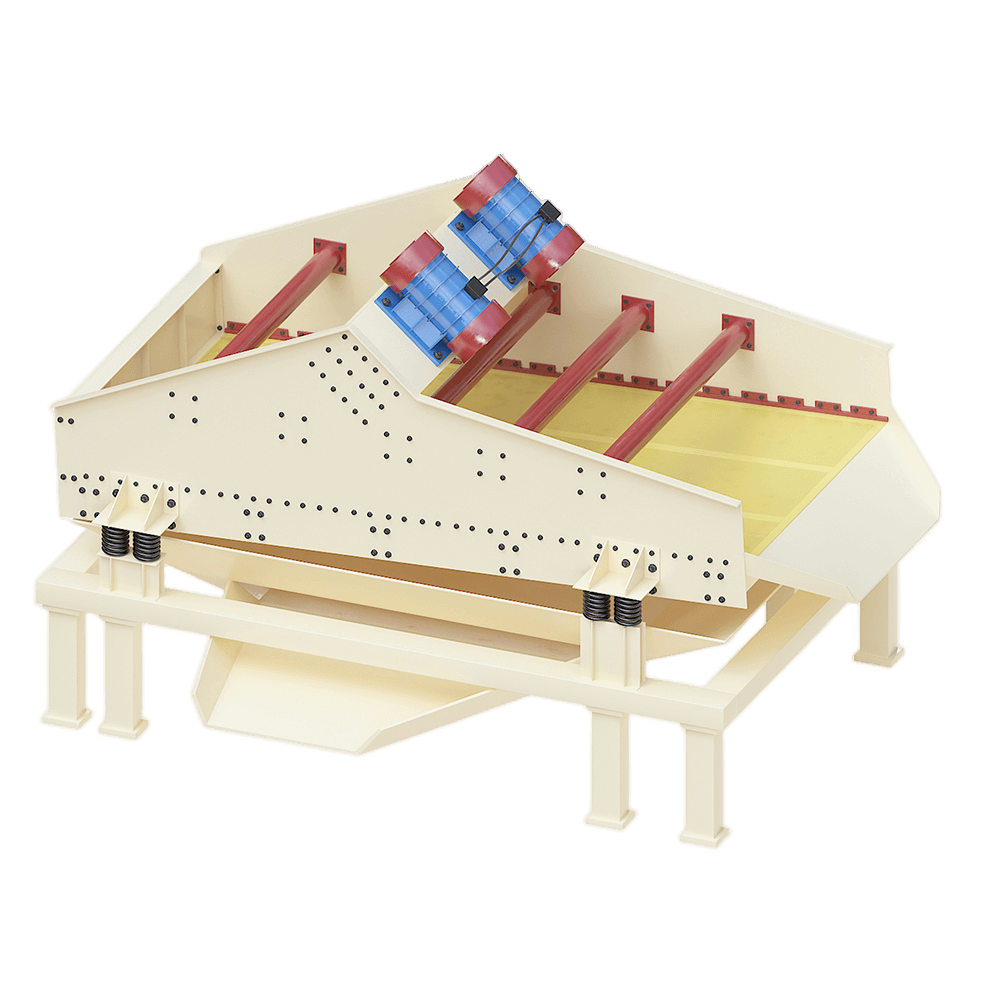

Dewatering screen

Capacity: customizable, 5-250 tph

screen sieve

Material: PU, PE, and others materials

Screen size: 1.6–10.8 mm

Application: Dewatering screens are mainly used in metal mine tailings, washed sand/machine-made sand, and dry tailings discharge plant.

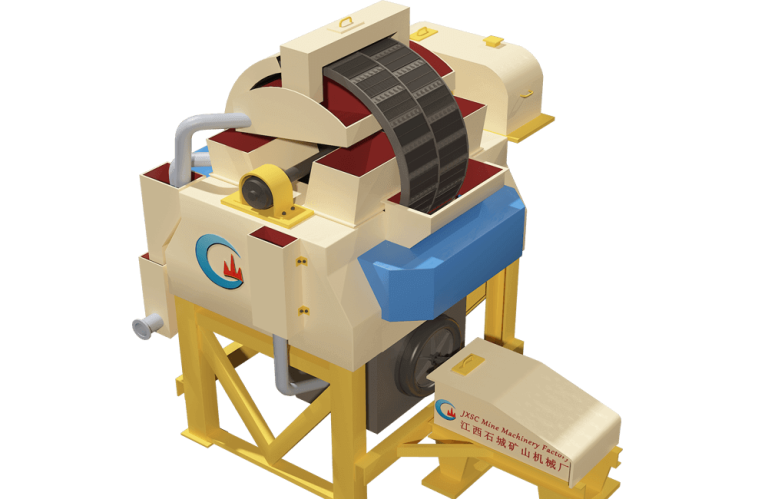

Thickener

Capacity: 1.3-1140 t/24h

Application: dewatering process of concentrates and tailings in the mineral processing plant. Specifically designed for the beneficiation and tailing processing, such as concentration of gold, copper, lithium, iron ore, manganese, antimony ore, lead-zinc, etc.

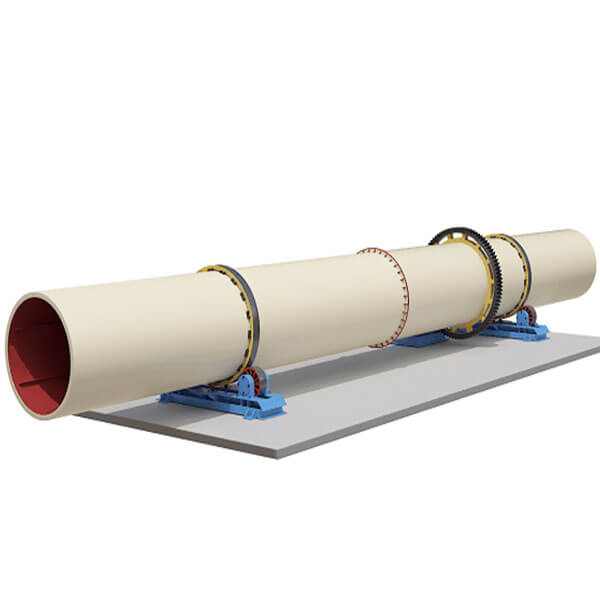

Rotary dryer

Capacity: 0.8-40 tons/hour

The rotary dryer’s core structure is an “inclined rotary drum + lifting plate + hot air system.”

Suitable materials: drying of various concentrates or non-metallic mineral powders, such as iron ore, copper ore, coal slime, ore powder, slag, sludge, clay, fly ash, etc.

Disc Vacuum Filter

Capacity: 0.85-1.2 t/h·m² (Different material processing capacity is different)

Application: It is suitable for fine material filtration and dehydration of fine tailings and non-ferrous metal concentrates in mineral processing plants, etc.

Belt pressure filter

Capacity: 0.5-30TPH

Slurry feed concentration: 3-8%

Application: dehydration and solid-liquid separation operations such as tailings mud, mineral processing wastewater, sand washing mud, sand plant sludge, etc.

plate Filter press

Filter area: 50-500 m²

Cake thickness: 30 mm

Application: Dehydration of sludge in sewage treatment plants; used to separate solid minerals and water in slurry, such as gold, coltan, tin, tungsten, iron tailings processing.

- Thickening equipment is used to increase slurry concentration and achieve solid-liquid separation. It primarily uses gravity settling or centrifugal separation to concentrate low-concentration slurry (90%-98% moisture content) into a high-concentration underflow (50%-70% moisture content).

- Dewatering equipment is suitable for concentrate dewatering, tailings dry discharge, and environmentally friendly recycling. It primarily dehydrates the concentrated material to a filter cake or dry residue with a moisture content of 10%-25%, which can be transported, stored, or reused (e.g., tailings dry discharge, concentrate drying).

As the core of the final processing stage of the mineral processing plant, our concentration and dehydration equipment is centered around efficient separation, low energy consumption, durability, and intelligent environmental protection. Their coordinated operation significantly reduces tailings pond capacity and water consumption, making them a key component of green production and cost control in mines.

Contact us for customized solutions, including specialized beneficiation equipment for gold, iron ore, copper, manganese, lead, and zinc, along with comprehensive technical support.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.