Double Impeller Leaching Agitation Tank

Application: Double impeller leaching agitation tank is commonly used for agitation leaching and carbon adsorption of slurry in cyanide, cip, cil gold extraction process.

Products display

Introduction of Double Impeller Leaching Agitation Tank

Double impeller leaching agitation tank, is also called high efficiency agitation tank, mining agitator. It is a stirring equipment that forces the slurry to circulate up and down in the tank. The rotation of the impeller is mainly achieved by the motor through the pulley and the V-belt to stir the slurry and reagents evenly. It is commonly used in the CIP, CIL gold extraction and cyanidation process of gold mines, where the slurry with a mesh size of more than 90% is stirred and leached, and carbon adsorption is used.

Working principle Of Double Impeller Leaching Agitation Tank

Under the rotation and stirring of the double impeller, the ore pulp moves downward along the damping plate and diffuses. The air enters the tank from the lower end of the shaft and mixes with the ore pulp to form a uniform suspension mixture.

- If the machine is used as a leaching tank, the leaching agent solution and air are loaded into the tank, and the leaching agent and air are evenly distributed in the tank to leach gold.

- If the machine is used as an adsorption tank, activated carbon or other substances with strong adsorption capacity are loaded into the tank to adsorb the gold dissolved in the solution.

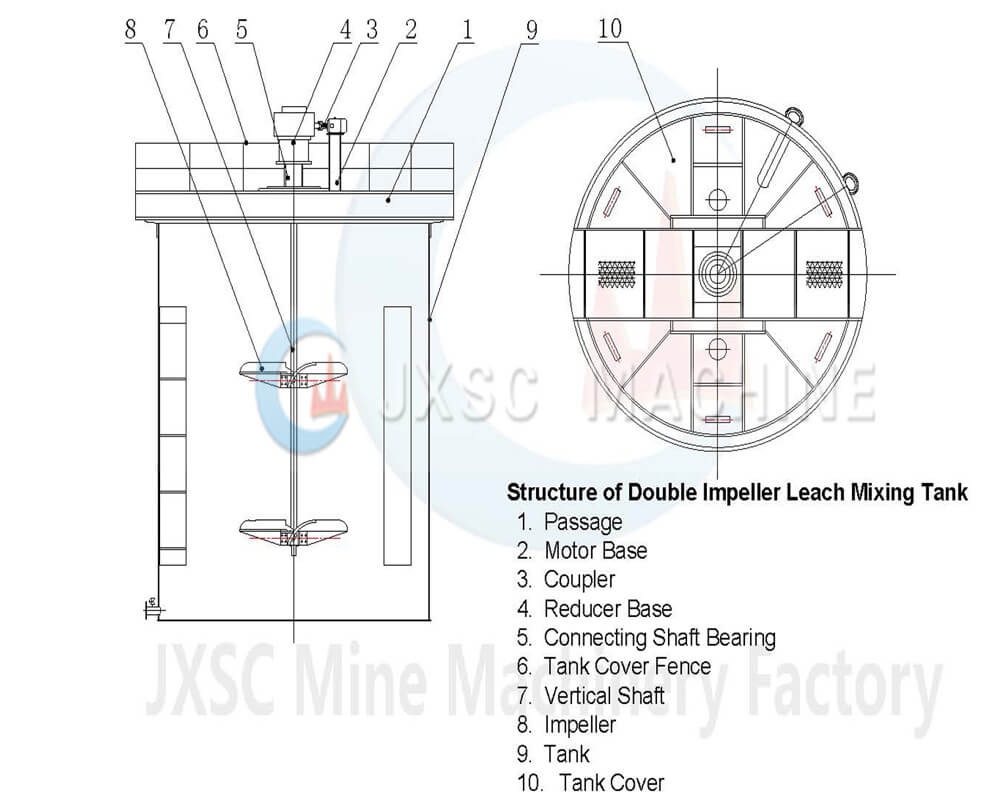

Structure of Double Impeller Leaching Agitation Tank

- Tank Structure: Constructed of thickened carbon steel or stainless steel, lined with anti-corrosion rubber or a polymer coating, resistant to acid and alkali corrosion.

- Upper Impeller (Main Impeller): Large-diameter blade design generates strong radial flow, ensuring thorough mixing of minerals and reagents.

- Lower Impeller (Auxiliary Impeller): Installed near the bottom of the tank to prevent sedimentation and create axial circulation.

- Motor and Reducer: A variable frequency motor is preferred, allowing for stepless speed adjustment to adapt to different slurry concentrations.

why choose JXSC Double Impeller Leaching Agitation Tank

features & Advantages

1. The two-blade new impeller has a large diameter, low speed, low power consumption, and reduces carbon wear;

2. The unique agitator structure makes the solid content of the slurry uniform at all positions of the tank body, avoiding particle sedimentation;

3. The stirring intensity is moderate, the concentration and fineness of the slurry are evenly distributed, and the adsorption rate and feed rate are improved;

4. The double-layer impeller can make the stirred slurry more uniform.

models & specifications

Model | Specifications (mm) | Effective capacity(m3) | Rotary Speed of Impeller(r/min) | Diameter of Impeller(mm) | Diameter of feeding pipe(mm) | Diameter of Discharging pipe(mm) | Planet cycloid reducing motor | Weight(kg) | ||

Model | Speed ratio | Motor Power(kw) | ||||||||

φ2.5×2.5 | 2500×2500 | 6 | 65 | 800 | 2-φ133 | 2-φ133 | XLD2.2-4-29 | 29 | 2.2 | 2800 |

φ2.5×3.15 | 2500×3150 | 13 | 57 | 935 | 2-φ125 | 2-φ125 | XLD2.2-4-29 | 29 | 2.2 | 3120 |

φ3×3.15 | 3000×3150 | 18.93 | 51 | 1130 | 2-φ150 | 2-φ150 | XLD4-5-35 | 35 | 4 | 5300 |

φ3.15×3.55 | 3150×3550 | 24 | 43 | 1260 | 2-φ150 | 2-φ150 | XLD4-5-35 | 35 | 4 | 5488 |

φ3.5×3.5 | 3500×3500 | 29 | 46 | 1310 | 2-φ150 | 2-φ150 | XLD5.5-5-29 | 29 | 5.5 | 7820 |

φ3.55×4.0 | 3500×4000 | 35 | 36.3 | 1310 | 2-φ150 | 2-φ150 | XLD4-5-35 | 35 | 4 | 6646 |

φ4.0×4.5 | 4000×4500 | 50 | 33.5 | 1500 | 2-φ150 | 2-φ150 | XLD7.5-7-43 | 43 | 7.5 | 8285 |

φ4.5×5.0 | 4500×5000 | 71.67 | 33.5 | 1750 | 2-φ159×6 | 2-φ159×6 | XLD7.5-7-43 | 43 | 7.5 | 10800 |

φ5.0×5.6 | 5000×5600 | 98 | 31 | 1900 | 2-φ159×8 | 2-φ159×8 | XLD11-8-47 | 47 | 11 | 13340 |

φ5.5×6.0 | 5500×6000 | 112 | 31 | 2100 | 2-φ159×8 | 2-φ159×8 | XLD11-8-47 | 47 | 11 | 18745 |

φ7.5×8.0 | 7500×8000 | 268.6 | 21 | 2900 | 2-φ159×8 | 2-φ159×8 | XLD22-10-47 | 47 | 22 | 32796 |

φ8.0×8.0 | 8000×8500 | 342 | 16.4 | 3200 | 2-φ159×8 | 2-φ159×8 | XLD22-11-59 | 59 | 22 | 42467 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.