Fine Sand Recycling Machine

Capacity: 30-250TPH

Application: Fine sand recycling machine is mainly used for dewatering and recycling fine sand and fine materials (slurry materials below 0.16mm). It is widely used in sand and gravel aggregate sand washing production lines, tailings recycling in mineral processing plants, silica/quartz sand processing systems, etc.

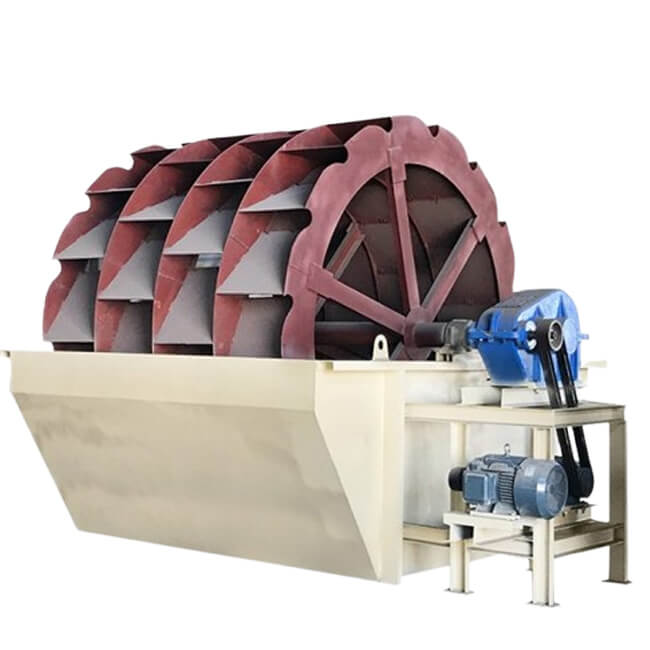

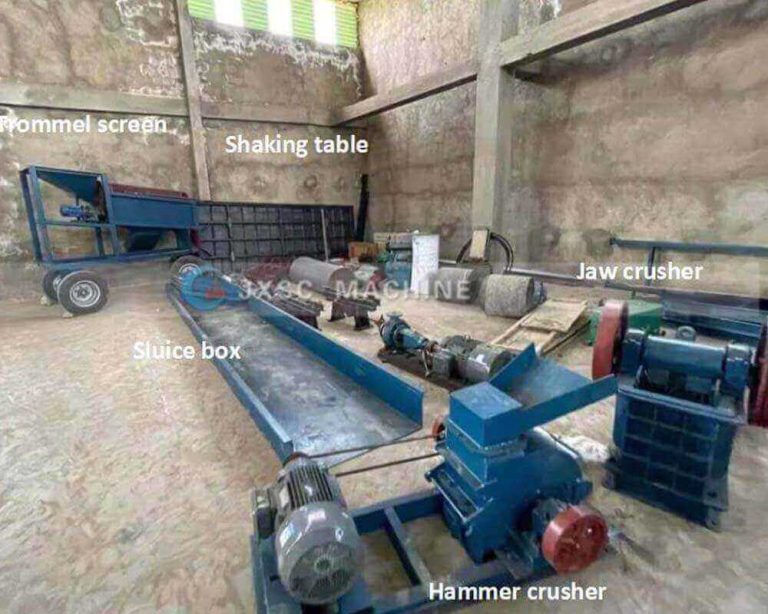

Products display

Introduction of Fine sand recovery machine

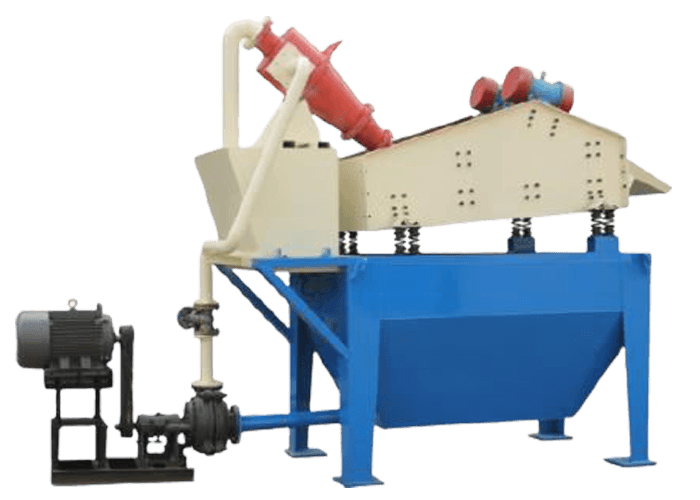

Fine sand recovery machine is also called tailing sand recovery machine, fine sand extraction machine, fine sand collector, sediment separator, mud separator, sand-water mixture treatment system, etc. The fine sand recovery machine mainly consists of a motor, a slurry pump, a sediment separator, a cyclone, a TS dewatering screen, a cleaning tank, and a return box. It can also be equipped with a sand washer to form a modular sand washing – dewatering – recycling integrated machine. It is mainly used to solve the problem of fine sand loss in the sand-making industry: good sediment separation, fine sand recovery, and wet sand dehydration.

When the sand washing machine washes the sand, it will inevitably cause the loss of fine sand. The lost fine sand may be contained in the sedimentation tank, and the fine sand may flow along the river. However, the existence of the fine sand recovery machine is to recover fine sand particles of less than 0.16mm that will flow away from the sedimentation tank.

The equipment’s return water utilization rate is >85%, saving 50% of water. The fineness modulus of its finished sand perfectly meets the standards for construction sand, and it has become the standard sand cleaning equipment for high-quality machine-made sand production and tailings resource utilization.

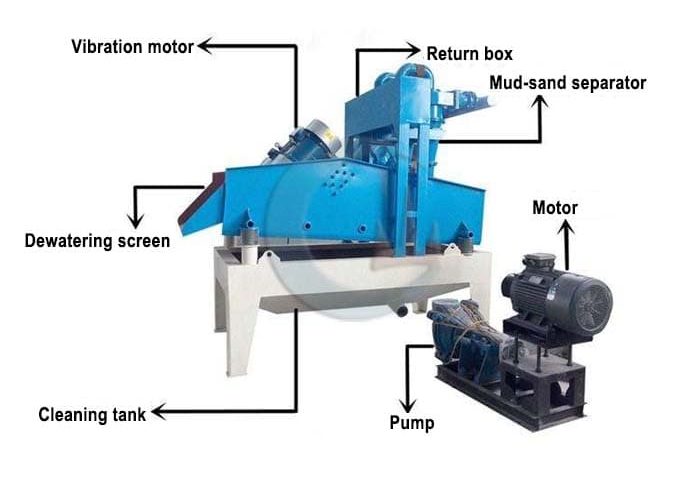

Principle and structure of Fine Sand Recycling Machine

Working principle

The slurry pump transports the sand-water mixture to the high-pressure mud and sand separator, and the centrifugally classified and concentrated tailings are supplied to the dewatering screen through the grit nozzle.

After dewatering through the dewatering screen, the tailings and water are effectively separated; a small number of tailings and mud return to the cleaning tank through the return box, mix with the mixed liquid returned by the cyclone, and are sent to the cyclone for separation again. When the liquid level in the cleaning tank is too high, it is discharged through the water outlet.

Structural characteristics

The system primarily consists of a motor, slurry pump, cyclone (centrifugal classifier), dewatering screen, cleaning tank, and return tank.

- Cyclone: It completes slurry concentration and liquid clarification and is the core component of classification.

- High-frequency dewatering screen: The screen material is polyurethane/rubber composite layer, which has a long service life and is not easy to clog the holes.

- Slurry pump: completes material transportation; uses wear-resistant alloy flow components.

- Return box: realizes the recycling of small amounts of fine sand and mud.

- PLC automatic adjustment: Real-time monitoring dynamically controls the flushing water volume based on the mud content of the raw material.

why choose JXSC Fine Sand Recycling Machine

Features & advantages

√ Improve Quality: The fine sand recovery machine can effectively reduce the loss of fine sand during sand washing and control it within 5%-10%.

√ High Recovery Rate: Over 85% of fine particles can be recovered, with loss controlled to 5%-10%, improving the quality of manufactured sand.

√ High Durability: The cyclone is lined with polyurethane, and the vibrating screen uses polyurethane mesh, ensuring a long service life and low maintenance costs.

√ Intelligent Adjustment: Supports PLC and touchscreen control, enabling multi-dimensional fineness modulus adjustment to suit different material properties and production needs.

√ Cost Optimization: Reduces sedimentation tank construction and cleaning costs, lowering energy consumption. Fine sand can be directly supplied to the market, resulting in a fast return on investment and excellent economic benefits.

√ Environmental Compliance: Reduces fine sand stockpiling and wastewater pollution, complies with national environmental standards, and contributes to green mining development.

√ Flexible Configuration: The JXSC supports customized configurations of sand washing machines, dewatering screens, and filter presses. Its modular design adapts to various modern sand and gravel, aggregate production lines.

models & specifications

Model | Dewatering Screen | Motor Power | Hydrocyclone | Slurry Pump | Power of Slurry Pump (kw) | Capacity(t/h) |

DN1224 | 1200*2400 | 2.2kw*2 | φ250*2 | 4/3AH | 15kw | 30-50 |

DN1530 | 1500*3000 | 3kw*2 | φ300*2 | 4/3AH*2 | 11kw*2 | 50-80 |

DN1840 | 1800*4000 | 5.5kw*2 | φ350*2 | 4/3AH*2 | 15kw*2 | 80-120 |

DM2045 | 2000*4500 | 11kw*2 | φ500*2 | 6/4AH*2 | 30kw*2 | 120-150 |

DN2245 | 2200*4500 | 15kw*2 | φ500*3 | 6/4AH*2 | 30kw*2 | 150-200 |

DN2445 | 2400*4500 | 18.5kw*2 | φ500*4 | 6/4AH*2 | 37kw*2 | 200-250 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.