Gemini shaker table

Application industry: Gemini shaker tables mainly used in gold mining, mining research and development, mineral processing plants, recycling and other industries.

Applicable materials: Gemini shaker tables are commonly used to sort and concentrate gold, tin, tantalum, tungsten, niobium, tungsten, iron, chromium, chalcopyrite, and other precious or base metals and are especially effective for fine gold recovery.

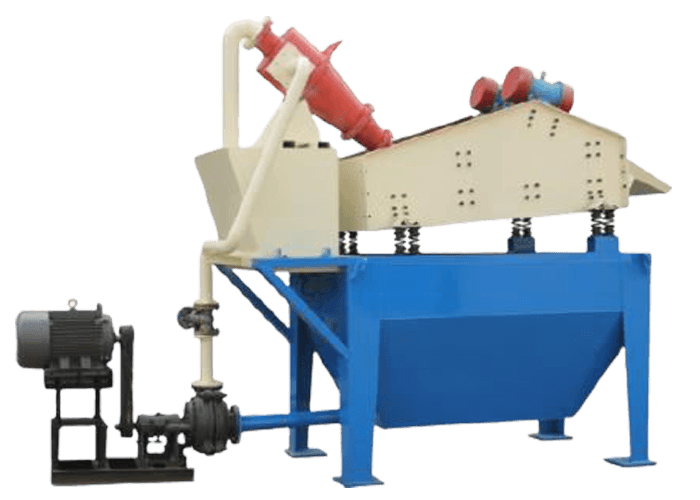

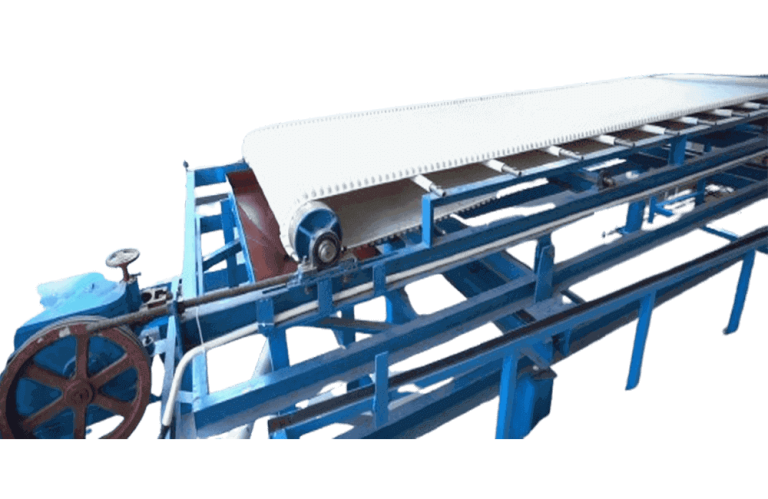

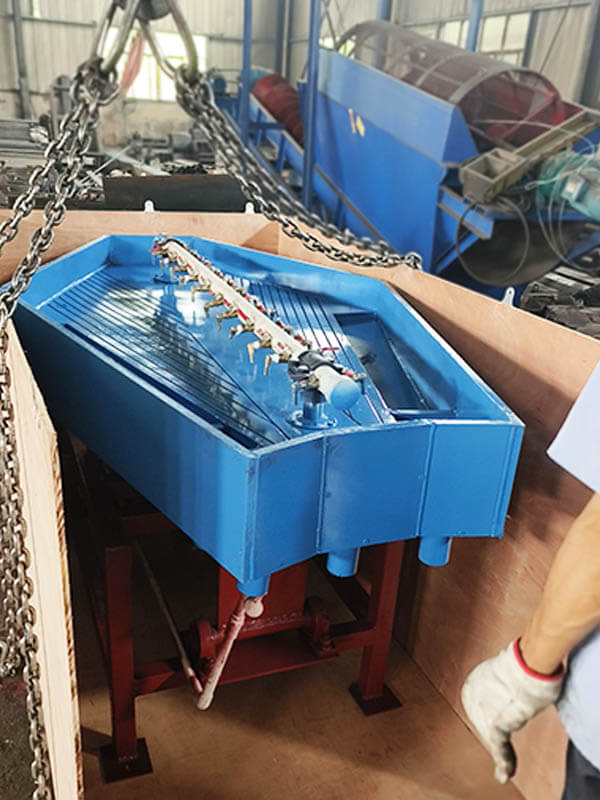

Products display

introduction of Gemini shaker table

Gemini shaker table is an important tool in mining gravity separator or laboratory testing, mainly used for sorting gold ores. The innovative design of its bed surface enables precise control of the separation process, ensuring that only the most valuable material is collected. The Gemini shaker table can produce gold bar-grade products with high recovery rates from low-grade concentrates. It is a mineral processing method that mainly uses the differences in relative density, particle size, and shape between the mineral particles to be sorted and the differences in movement rate and direction in the medium (water, air, or other relatively dense liquids) to separate them from each other.

Gemini shaker tables are known for their high recovery rates, making them a popular choice for mineral processing operations to extract valuable metals from ores.

It is mainly used for the fine separation of precious metals (gold, silver), tungsten-tin ores, rare earth ores, iron ores, etc. It is especially suitable for small and medium-sized concentrators and complex mineral separation. Upgrading low-grade minerals (e.g., 0.1g/t gold ore) to high-grade concentrates (e.g., 50g/t) in one go, with a recovery rate up to 98%. The reagent-free and mercury-free process reduces pollution and meets the “zero emission” mineral processing requirements of green mines.

working principle of Gemini shaker table

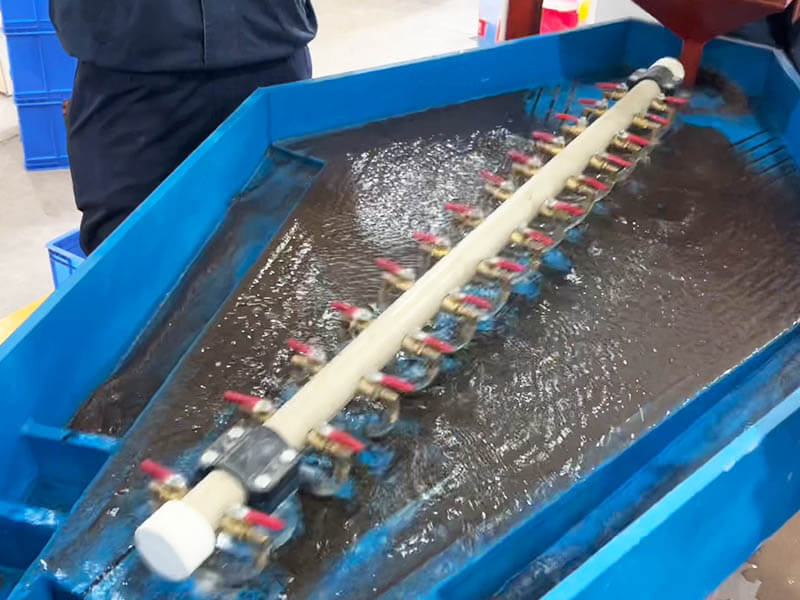

Gemini vibrating table consists of a transmission device, electric motor or diesel engine, slope regulator, bed, ore tank, water tank, lubrication system, etc. A broad, approximately rectangular bed surface allows the mineral particles to move in different directions according to their different densities and particle sizes.

It starts from the ore feeding trough, spreads out diagonally in a fan shape, and is discharged along the edge of the bed in turn. The ore discharge line is very long. The raw slurry is fed from the upper left corner of the bed side, and flushing water is fed simultaneously. The mineral particles are affected by two movements on the bed surface.

On the one hand, they move longitudinally along the bed surface; on the other hand, they move transversely along the bed surface. Eventually, the ore particles flow down in a fan shape and are divided into layers according to specific gravity. It can accurately produce various products with different qualities, such as concentrate, sub-concentrate, medium concentrate, and tailings.

why choose JXSC Gemini shaker table

Features & advantages Of Gemini Shaking table

1. High processing efficiency: Large enrichment ratio and high recovery rate.

2. Adjustable: The Gemini shaking table can operate intermittently or continuously, with single-phase or three-phase power supply.

3. Durable and economical: Equipped with high-quality components and durable materials for long service life.

4. Environmental protection and safety: Low environmental impact, low energy requirements and low maintenance.

5. Typically with adjustable parameters such as platform inclination, travel and frequency.

models & specifications

Model | GT60 | GT250 | GT1000 | |

Operating dimensions | Length(mm) | 1490 | 2180 | 2800 |

Height(mm) | 1160 | 1350 | 1365 | |

Width(mm) | 894 | 1340 | 916 | |

Bracket width(mm) | 670 | 700 | 1750 | |

Wash Water(L/Min) | 12 | 25 | 38 | |

Approximate packed dimensions | Length(m) | 1.42 | 2.2 | 2.8 |

Height(m) | 1.21 | 1.5 | 1.5 | |

Width(m) | 1.1 | 1.5 | 1.9 | |

Packed weight est(Kg) | 300 | 420 | 540 | |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.