Roller Electrostatic separator

Capacity: 1.5-3TPH

Feeding size: 0-2mm

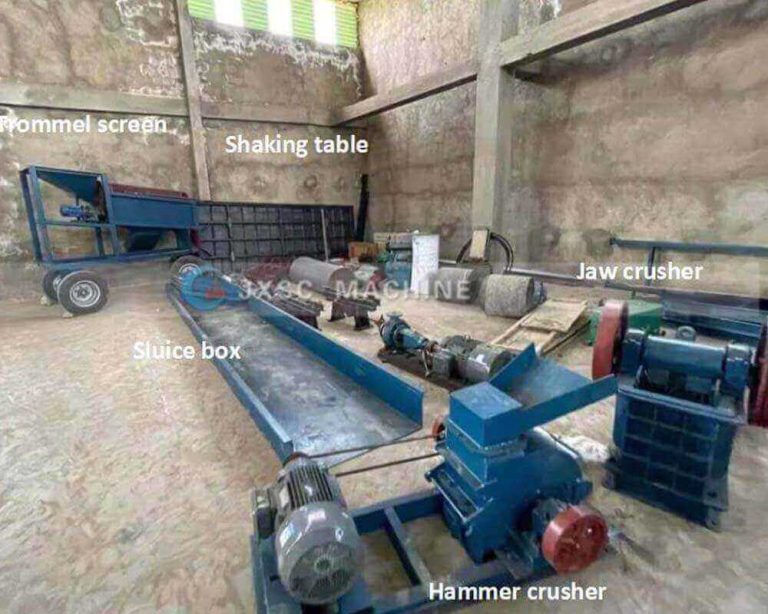

Application: Roller electrostatic separator is mainly used to configure multi-stage electrodes to achieve conductor-semiconductor-non-conductor step dry separation. For example, the selection of conductive heavy minerals such as ilmenite, zircon, rutile, and seashore sand ore; the purification of conductive minerals such as tantalite (tantalite and niobium iron ore), spodumene, quartz sand, and feldspar.

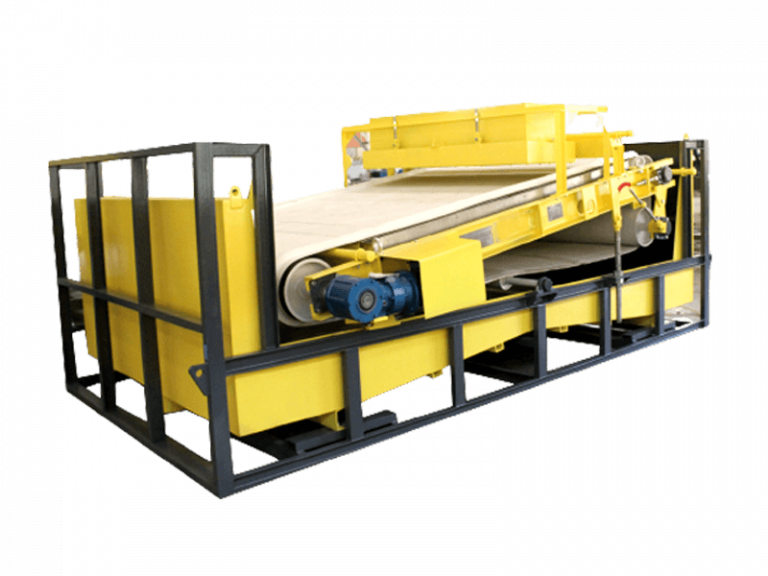

Products display

introduction Of Roller Electrostatic separator

Roller electrostatic separator is a dry physical separation equipment that achieves efficient separation based on the difference in material conductivity. Through the action of a 5~100kV high-voltage electrostatic field, materials with different electrical properties are separated by motion trajectories. Through separation and purification, valuable components are recovered or impurities are removed, thereby improving resource utilization. It specializes in the separation of non-ferrous metal ores, electronic waste, and high-purity quartz sand, and achieves a purity of 99%. It can be configured with multiple separation stages (2-4 stages) to obtain higher purity products at one time (Achieve separation of three types of concentrates: conductor, semiconductor and non-conductor).

Roller electrostatic separators are widely used in the fields of non-ferrous metal recovery, rare metal separation, and mineral purification, such as: separation of beach sand (separation of titanium, zirconium, rare earth, monazite, and garnet); preparation of high-purity quartz sand (SiO₂>99.9%), etc. The multi-electrode dynamic adjustment system, wear-resistant intelligent structure, and ultra-low energy consumption make it an irreplaceable green mineral separation equipment in the field of resource recovery and mineral purification. With outstanding advantages such as high sorting accuracy, no water resource consumption, environmental protection, and energy saving, this electrostatic separator is particularly effective in processing fine-grained zircon, rutile, ilmenite, gold, tin, tungsten, tantalum-niobium, etc.

JXSC state-of-the-art electrostatic separators feature either two or four rollers (with the four-roller configuration offering higher processing capacity) to maximize mineral separation efficiency for various applications. Whether you are processing beach sand or complex ores, JXSC customizable roller or arc plate electrostatic separators provide reliable performance and high throughput.

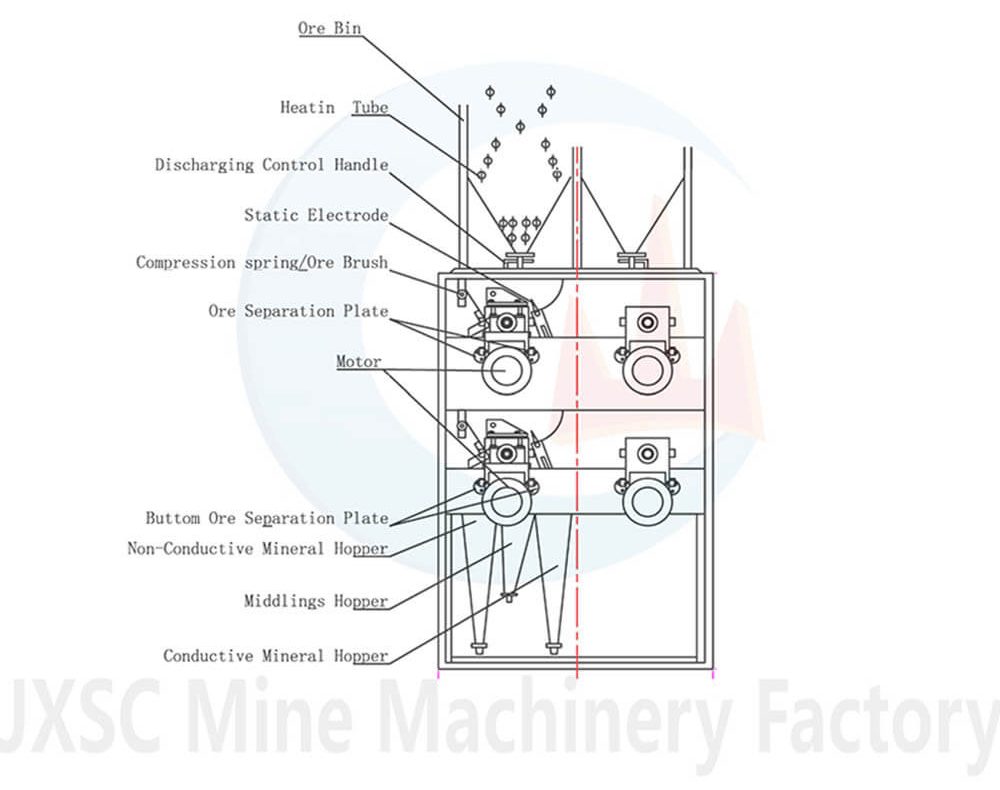

structure & working principle of Roller Electrostatic separator

The roller electrostatic separator is mainly composed of high-voltage power supply system, rotating sorting roller, feeding vibration system, ore separation partition and other components.

The material is evenly spread on the surface of the rotating grounded roller through the vibrating feeder. Under the action of the high-voltage corona electrode in the corona discharge area, the material particles with different conductivity are charged with different polarities due to contact charging or induction charging. Under the combined action of electric field force, centrifugal force and gravity, the charged particles move in different directions. Among them, the conductive material: discharges quickly and is thrown away by the roller inertia (parabolic trajectory). Semiconductor material: partially discharged, attracted by the static electrode and presents a medium throwing trajectory. Non-conductive material: keeps the charge adsorbed on the roller surface and is peeled off by the brush. These three types of materials fall into different collecting hoppers to achieve precise sorting.

why choose JXSC Roller electrostatic separator

Features & advantages

1. With 3~5 separation intervals, the mineral separation purity is as high as 99%, and the three products of conductor/medium ore/non-conductor are produced simultaneously.

2. This drum electrostatic separator uses PLC to automatically adjust the voltage, roller speed, and pole distance, and the response speed is timely.

3. By adjusting the parameters such as roller speed, electrode voltage, and plate position, it can adapt to the processing of a variety of materials.

4. The material passing through the drum electrostatic separator is of high purity, which can fully meet the requirements of maximizing the grade of the target product.

5. The separation process does not require the addition of chemical agents, there is no secondary pollution, and the energy consumption is relatively low.

6. Self-cleaning roller surface + ultrasonic vibration device, high anti-sticking technology.

7. The key components of the equipment are made of wear-resistant and corrosion-resistant materials, stable and reliable operation, and long service life.

8. High degree of automation, continuous operation can be achieved, and manual intervention can be minimized.

9. Water-free sorting technology is suitable for arid areas and water-free process scenarios.

10. JXSC supports the configuration of two or four-roller electrostatic separators to meet different production capacity requirements.

models & specifications

Model | JXSC-1615 | JXSC-1815 | JXSC-2215 |

Roller Size (mm) | 160*1500 | 180*1500 | 220*1500 |

Feeding size(mm) | 0-2 | 0-2 | 0-2 |

Double roller capacity(t/h) | 1 | 1.5 | 2 |

Four roller capacity(t/h) | 1.5 | 2 | 3 |

Double roller power | 1.5 | 1.5 | 1.5 |

Four roller power | 3 | 3 | 3 |

* Note: Technical parameters may vary slightly depending on material characteristics and operational conditions.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.