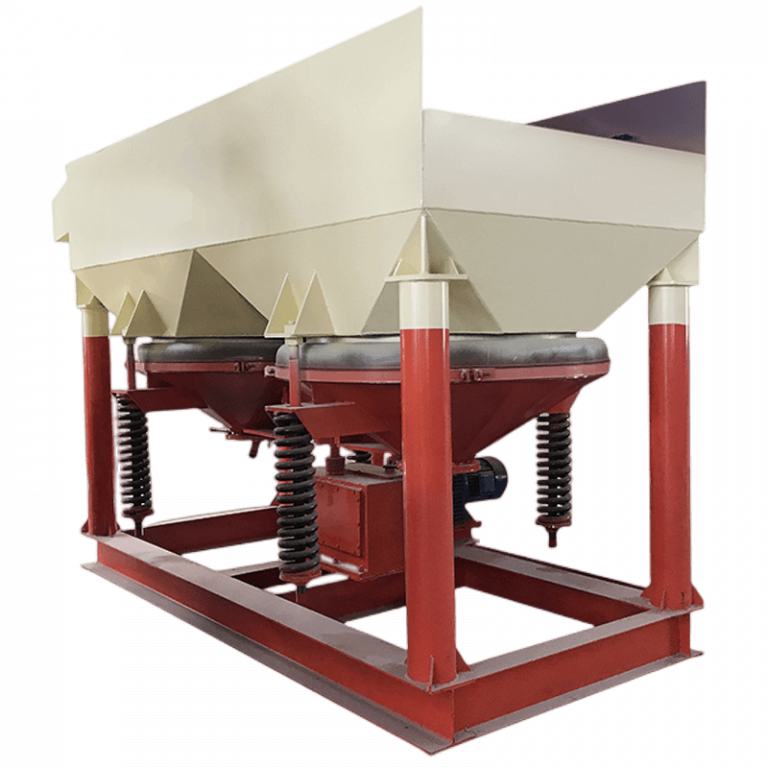

Vibration Tailings blanket recycling machine

Application: The vibration tailings blanket recovery machine is mainly used to re-extract and utilize the tailings and waste tailings discharged from the mineral dressing plant; it is often used in the gold tailings gravity separation stage, and can also be used to recover tungsten, tin, copper and other metal minerals in magnetite, pyrrhotite and roasted hematite, limonite and siderite.

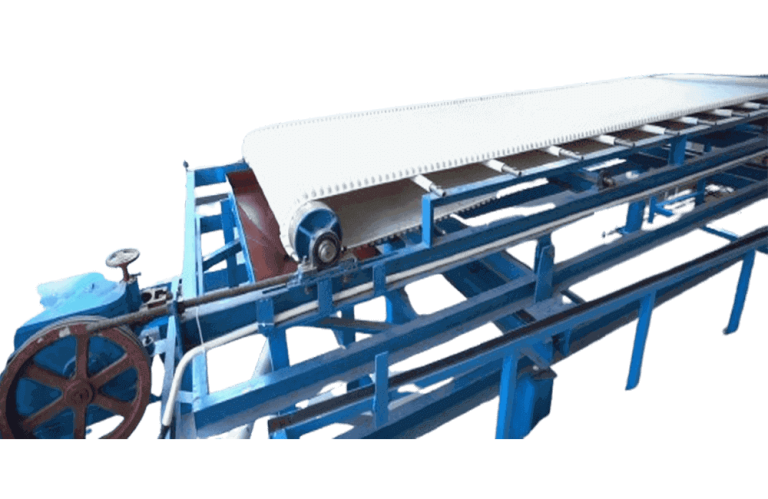

Products display

introduction of Vibration Tailings Blanket Recycling Machine

Vibration tailings blanket recycling machine is also called cloth chute machine, fully automatic blanket machine, vibration suspension woollen blanket chute, suspended vibration blanket concentrator. It is a new and unique gold tailings gravity separation equipment, and can also be used for secondary purification of tailings such as tungsten, tin, copper, lead, zinc, chromium, titanium, zirconium, rare earth, rutile, monazite, garnet, quartz, kaolin, etc. It has high rich ore ratio, high separation efficiency, easy supervision and convenient adjustment.

work principle of Vibration Tailings Blanket Recycling Machine

The tailings blanket recovery machine mainly uses filtration and separation technology to extract useful minerals from the tailings.

The blanket, as a filter medium, can effectively capture particles in the tailings and use the power of water flow to separate useful minerals from waste. When the minerals attached to the surface are turned to the bottom, they are backwashed by water and fall into the collection bucket.

why choose JXSC Vibration Tailings Blanket Recycling Machine

Features & advantages Of automatic blanket recovery machine

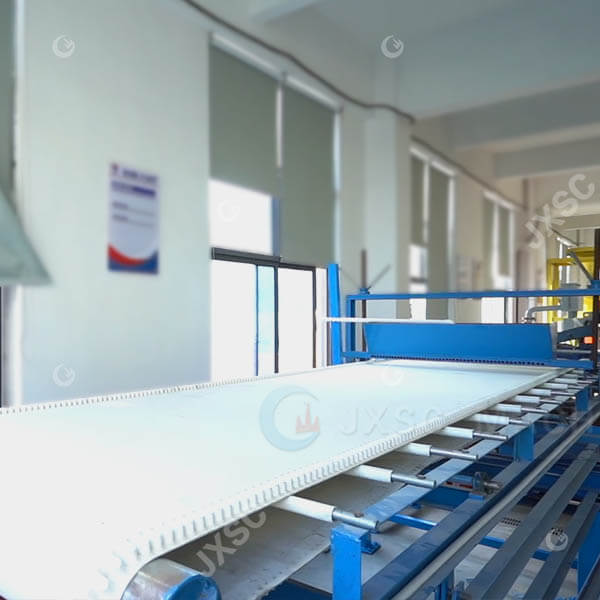

1. It occupies a small area, but has a large working area, large processing capacity, and high recovery rate, which fully plays the most significant effect of reducing costs, increasing profits, and saving resources;

2. The concentrate concentration ratio is high, and it is often used in conjunction with a shaking table or centrifugal concentrator to further refine the concentrate;

3. Using copper core motor, which has sufficient power, low noise, and strong overload resistance;

4. The machine also automatically discharges tailings and automatically recovers concentrates, truly saving manpower and material resources;

5. The angle and speed of the mining blanket machine can be adjusted, which facilitates the recovery of different minerals;

6. The frame is firmly welded and made of thickened steel, with a long service life.

models & specifications

Dimensions(mm) | 1400*5000*850 mm | Water consume(t/h) | 0.7-1t/h |

Voltage(v) | 380V | Feeding Size(mm) | <0.5mm |

Slope Adjust | 1-30° | Working surface | Special wear-resistant and easy-to-catch carpet |

Feeding Density | 5-20% | Output power(kw) | 0.37kw |

Output Speed(r/min) | 4-40r/min | Capability(t/h) | 1.5-2.5t/h |

Feeding Hopper | Conttolled Hopper | Beneficiation Area(Square) | 4.8m2 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.