Gold CIL processing

CIL (Carbon In Leach) is a gold extraction method developed from the carbon-in-pulp (CIP) process. This technology integrates activated carbon into the cyanide leaching tank, enabling simultaneous adsorption and leaching of gold, significantly improving recovery and production efficiency. An eco-friendly and compliant mineral processing solution.

Application: The gold CIL process is suitable for beneficiating oxidized gold ores with low sulfur content and high mud content, fine-grained disseminated gold ores, gold tailings after amalgamation with gravity separation, or other complex associated minerals.

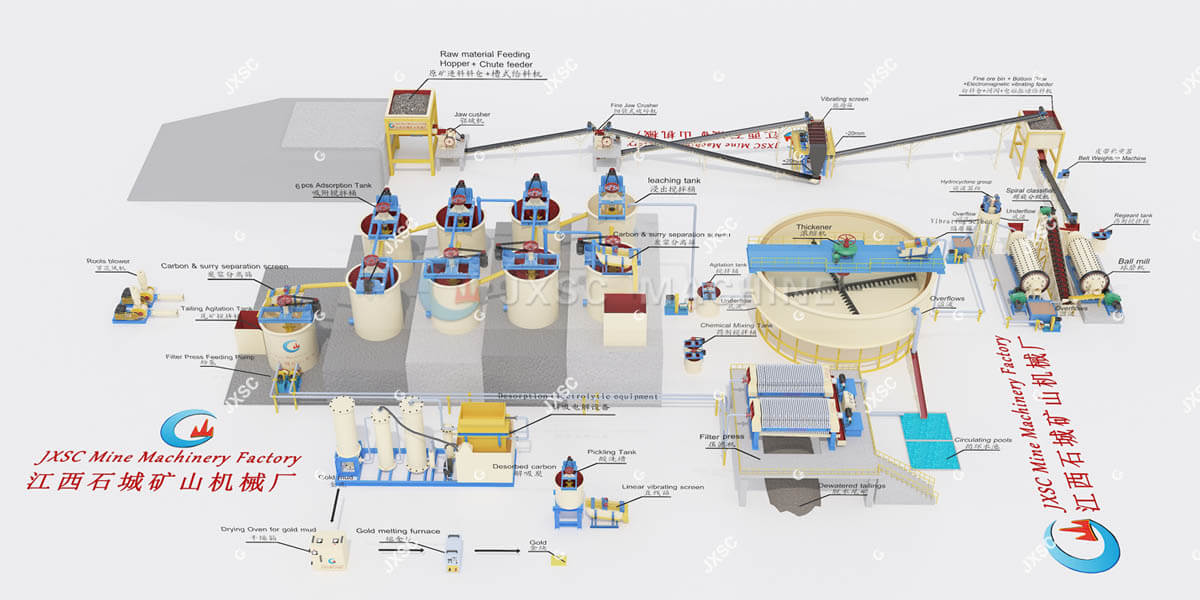

Gold CIL Process

Modern CIL plants also integrate an advanced desorption and electrolysis system. Utilizing high-temperature, high-pressure desorption technology, the gold-loaded carbon completes the entire desorption and electrolysis process within 24 hours, ultimately producing gold ingots with a purity of 99.9%. This leaching process incorporates activated carbon into the ore slurry, allowing for simultaneous leaching and adsorption, simplifying the CIP process. The gold CIL process flow primarily includes crushing, grinding, leaching, desorption and electrolysis, and tailings dewatering.

Gold Carbon in Leach Process

1. Crushing and Grinding

Gold ore is coarsely crushed in a crusher (jaw crusher + cone crusher) and then finely ground in a ball mill or semi-autogenous mill to a -200 mesh size, representing at least 90%, to ensure complete dissociation of the gold minerals and improve leaching efficiency.

2. Slurrying and Cyanide Leaching

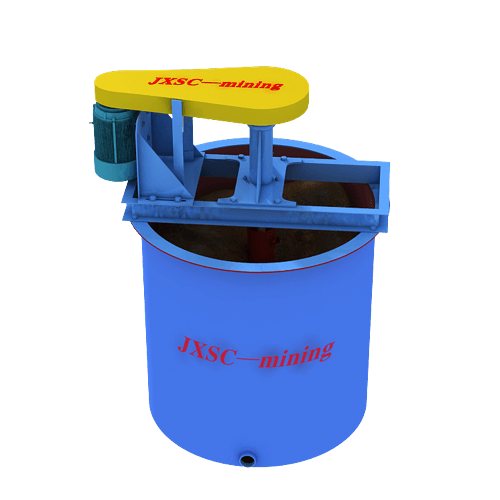

The slurry enters an agitated tank, where the pH is adjusted to 10-11 (controlled by lime) to enhance cyanidation. Sodium cyanide (NaCN) solution is then added. Under oxygenated conditions, the gold is dissolved to form a gold-cyanide complex.

3. CIL Adsorption Stage (Core Process)

The slurry flows into a series of CIL adsorption tanks (typically 6-12). Each tank is filled with coconut shell activated carbon (6-16 mesh particle size) in countercurrent contact with the slurry. Under agitation, the activated carbon efficiently adsorbs the gold-cyanide complex, achieving an adsorption capacity of 300-600g Au/ton of carbon. The barren liquid after adsorption is returned to the leaching tank for recycling, while the gold-loaded carbon is separated and recovered via a vibrating screen.

4. Gold-Loaded Carbon Desorption and Electrolysis

High-grade gold-loaded carbon enters a high-temperature, high-pressure desorption system, where it is rinsed with a NaOH-NaCN mixture to desorb gold from the carbon. The desorption solution is heated in a plate heat exchanger and then enters the electrolytic cell, where it deposits on a stainless steel cathode plate to form a gold sludge (40%-50% gold content). The electrolysis tailings are then recycled back into the desorption system. Direct current is then passed through the electrolytic cell, causing gold ions to deposit on the cathode (stainless steel plate) to form a gold sludge with a purity exceeding 99.5%.

5. Smelting and Tailings Treatment

The gold sludge undergoes acid washing and smelting in a 1500°C medium-frequency furnace, resulting in gold ingots (purity >99.9%). The tailings slurry passes through a safety screen to recover fine carbon particles before entering the tailings treatment system. Finally, it undergoes dehydration, dry discharge, or further processing before being stored to ensure compliance with environmental standards.

Carbon-in-leach gold plant is a complex process involving the leaching and adsorption of competing substances, the effects of cyanide, oxidants, and passivating agents, and carbon abrasion. JXSC has 40+ years of experience designing and optimizing gold processing solutions. Whether it’s oxide ores, sulfide ores, or difficult-to-treat gold ores containing arsenic or carbon, contact us to customize gold carbon in leach plant.

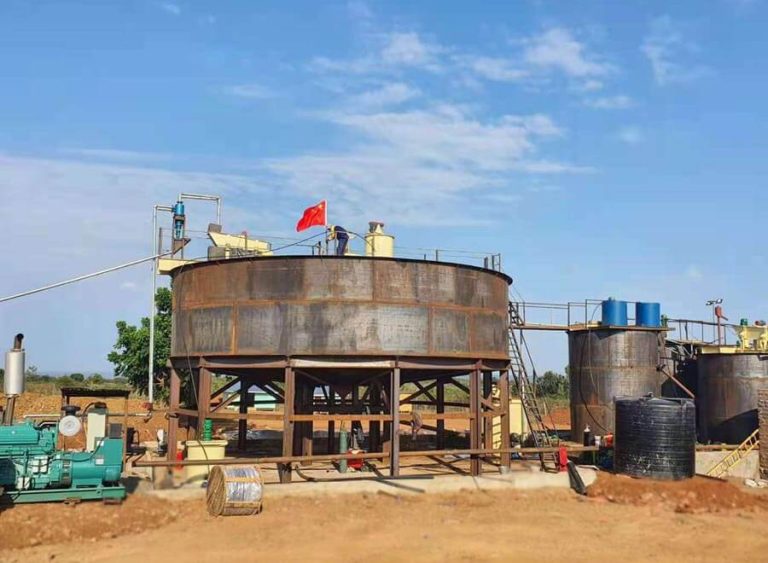

CIL Gold Processing Plant

Gold Carbon in leach processing plant

The gold CIL processing plant mainly includes the preparation of leaching slurry, cyanide leaching, activated carbon adsorption, gold-loaded carbon desorption, obtaining gold mud through electrolysis, recycling of gold-depleted carbon, and processing of leaching slurry.

Gold CIL processing flow

(1). Feeding, crushing, and screening system: Dump trucks deliver gold ore into the hopper, where it passes through a vibrating feeder to a jaw crusher. A two-stage jaw crusher crushes the ore to less than 25mm. After classification on a vibrating screen, qualified material (<25mm) is conveyed to a ball mill via a conveyor.

(2). Grinding system: Two-stage ball mill process: After the primary milling process, the ore is separated by a spiral classifier, and the coarse sand is returned for re-grinding. The overflow slurry enters a hydrocyclone. The cyclone underflow enters a secondary ball mill, ultimately ensuring that 90% of the ore fines reach a 200-mesh fineness, meeting leaching requirements.

(3). Pre-Leaching Pretreatment: The cyclone overflow slurry is screened for impurities before entering a thickener, where a flocculant is added to accelerate settling. The thickener underflow slurry is pumped into an agitator tank and then into the primary leaching tank for initial leaching.

(4). Leaching and activated carbon adsorption: Eight dual-impeller agitator tanks, equipped with activated carbon and Roots blowers, simultaneously perform leaching and adsorption. The number and size of the tanks can be adjusted based on the processing volume and ore characteristics.

(5). Gold-loaded carbon desorption and electrolysis: The gold-loaded carbon is vibrated to remove impurities. Desorption and electrolysis are then performed under normal temperature and pressure.

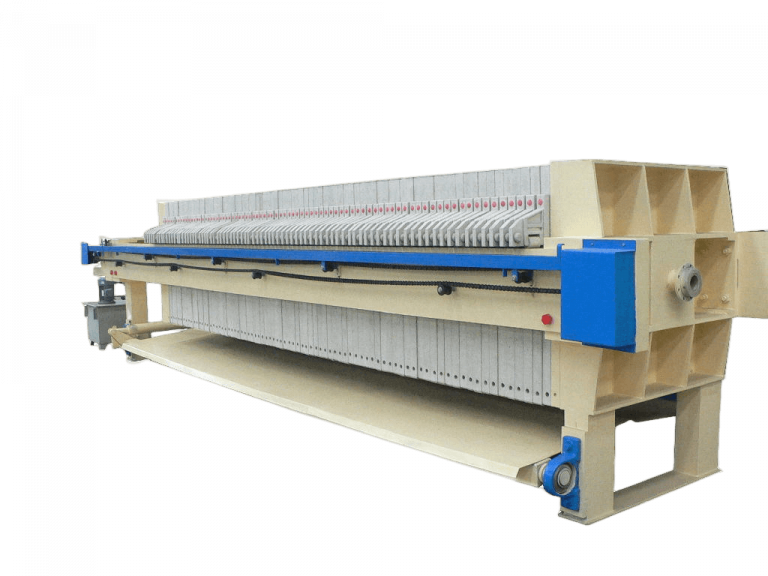

(6). Tailings water treatment: The tailings are first screened to remove activated carbon. After concentration adjustment in a thickener, they are dewatered using a plate and frame filter press. The water is recycled, and the dry tailings are transported away. If water is not recycled, bleaching powder is added to neutralize the acidic agents before discharge.

Custom Gold CIL Plant

0:34

6:30

1:31

Advantages Of CIL Process

- Wide Applicability: Suitable for all types of gold ores and tailings.

- Efficient Crushing: Two-stage jaw crusher + vibrating screen form a closed-circuit system for high crushing efficiency.

- Premature Recovery of Free Gold: quickly recover a part of liberated gold from ball mill with a gravity separation machine.

- Process Optimization: Two-stage grinding + classification ensures leaching fineness and improves subsequent recovery.

- Maximized Recovery: Gold recovery rate up to 95%.

Looking for the best gold extraction solution for your mine? Contact us to get a tailor-made gold CIL/ CIP processing plant flow & mining equipment quote!

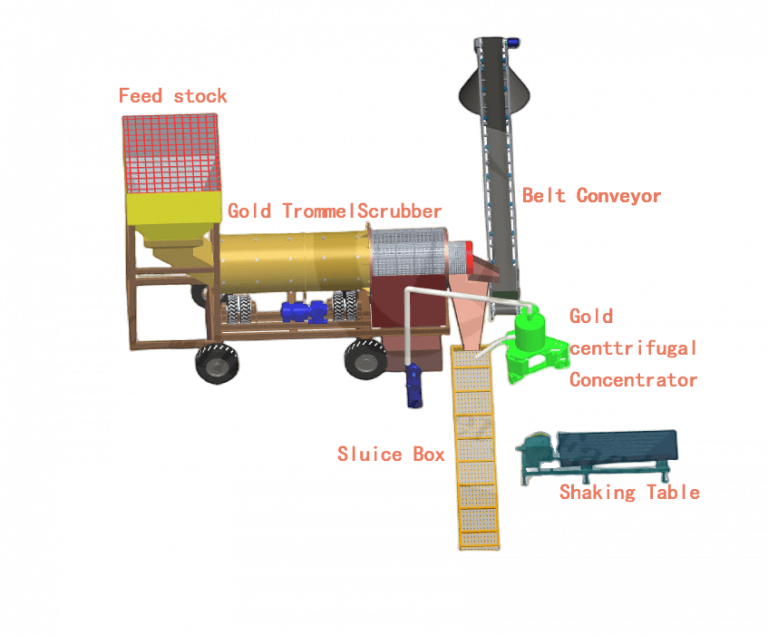

Other Gold Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.