Hard rock Gold mining process

Advanced Mineral Processing Turnkey Solutions | ISO Certified Equipment

Hard rock gold processing plant is an integrated system designed to extract & separate gold from various rock minerals through a series of beneficiation processes. JXSC supports customized hard rock gold (vein gold) mining process and specialized separation equipment. From crushing, grinding, gravity separation, flotation, leaching, cyanidation, or melting, every stage of the process is used for refining or purifying the ore. It can also be used for beneficiation in quartz vein type, sulfide type, low-grade oxide gold ore, etc.

- 95%+ Recovery Rate Guaranteed.

- Low energy consumption cost.

- Mining Equipment, 100% factory price.

- Modular Design, Complete Turnkey Solutions.

Hard Rock Gold process

The rock gold mining process including crushing, grinding, beneficiation process, it’s mainly to extract valuable gold from rock ores. High efficiency, low operating cost, and can recover even fine gold particles efficiently. The following three stages are usually adopted.

Rock Gold Mining Process

- Crushing: Mainly using two stage-one closed-circuit or a stage-one closed-circuit process. The jaw crusher or cone crusher is used for coarse ore; then, using a fine crusher for medium and fine ore crushing operations.

- Grinding: For the requirement of gold ore grinding fineness, a ball mill is usually used together with a classifier, and the qualified particle size is below 200 mesh.

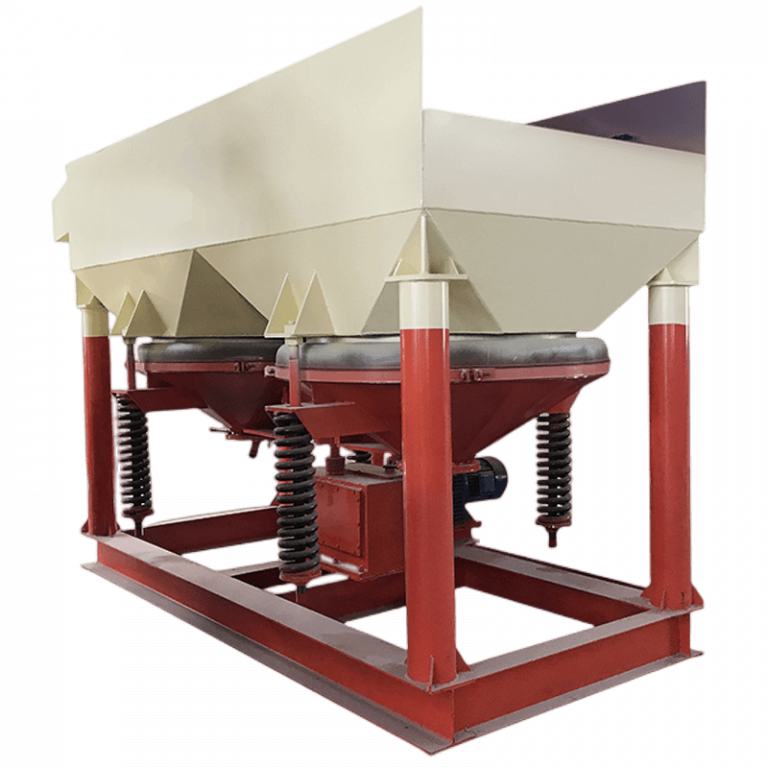

- Gravity separation: The gravity separation process is mainly used to separate rock gold deposits with simple structure and coarse grain size, especially the oxide rock gold deposits with high density. It relies on large differences in density between the targetmetal (gold) and the materials in which it is found. Mian gravity separation equipment including sluices box, spiral chute, jigs, centrifugal concentrator and shaker tables.

Due to gold ore usually containing a variety of minerals or impurities, it is necessary to use a combination of multiple processes for separating, such as: washing, flotation, magnetic separation, electric separation, CIP, CIL, etc. The specific process will be optimized according to your ore characteristics (such as hardness, gold particle size). Contact us to customize the process and equipment for small to large rock gold processing plants!

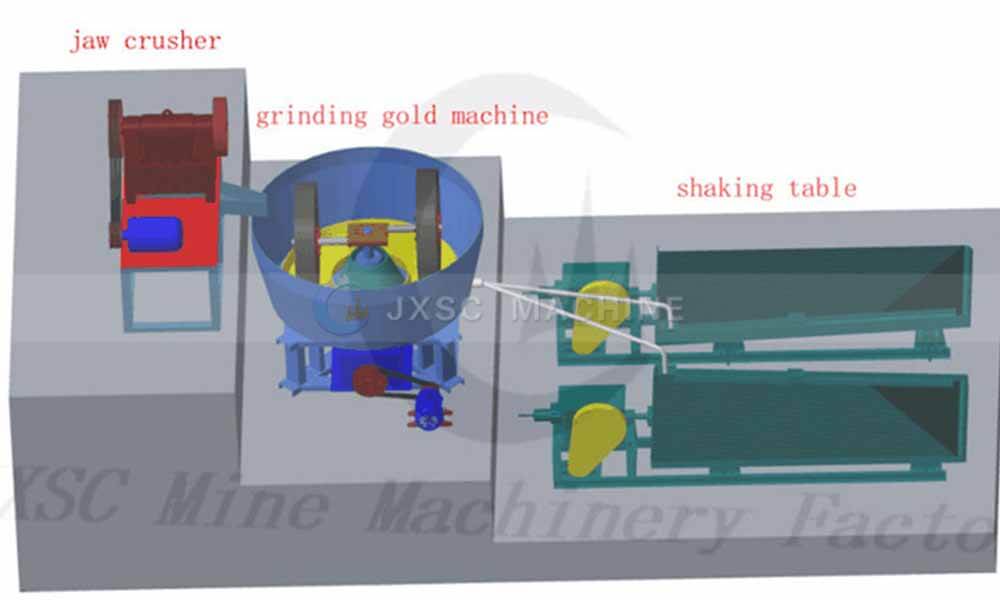

hard rock gold processing plant

♦ rock gold processing plant

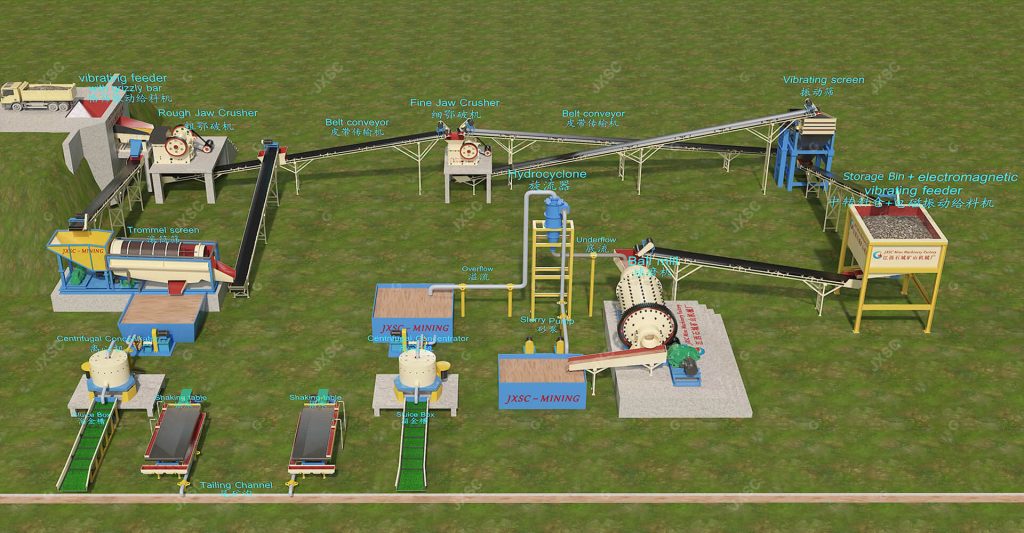

The following is a detailed description of the rock gold processing plant flow:

1. The raw ore is evenly fed into two jaw crushers by vibrating feeder for primary and fine crushing, crushing large rocks into smaller sizes.

2. Then, the material is fed into the vibrating screen, and the oversized stones are transported back to the fine gold crusher for further crushing;

3. The undersized ore into the transfer ore bin, the fine ore is transported to the ball mill via an electromagnetic vibrating feeder to grind the ore into powder. The ball mill and the spiral classifier form a closed-loop grinding device. The coarse particles are returned for re-grinding, and the materials into the centrifugal concentrator by a slurry pump to separate fine gold.

4. The tailings enter the sluice box to recovery more gold; all concentrates are sent to the shaking table to finely concentrate the gold. Then it goes into the gold melting furnace to be refined into gold bars

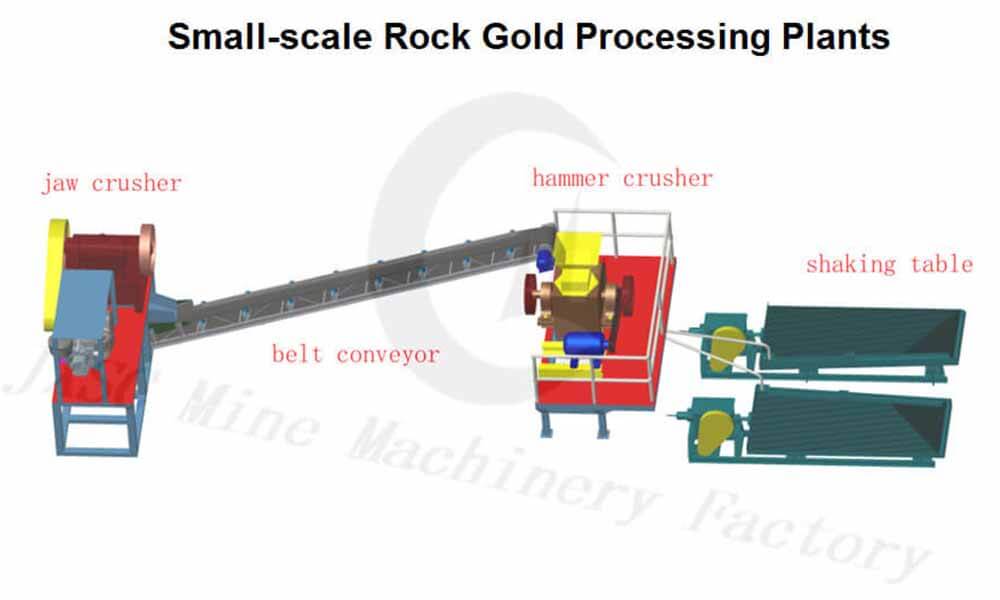

♦ rock gold crushing plant

Jaw Crusher + Hammer Crusher Plant

This setup is a 5-10tph vein gold ore crushing plant, main equipment and flow details as follows:

1. The trough feeder can feed evenly to the crusher. Jaw crusher preliminary crushing of large rocks can also be made mobile type as requested. The hammer crusher output size is adjustable like 10mm,5mm, etc. For this project, the materials are ground to 0-2mm; it can also be made mobile type as per request.

2. Using a shaking table to recover fine gold, then it is melted into gold bricks through a gold melting furnace.

This plant can also be used for processing hard rock tin ore, coltan ore, tungsten ore, chrome, copper, etc. The capacity can be customized as requested, such as 20tph, 50tph, 100tph, etc.

Note: In such a small rock gold processing plant, if ultra-fine grinding (such as nanometer level) is required, oxidation agglomeration prevention is required, or fine slurry is directly produced for wet gold extraction processes such as cyanide leaching, a wet pan mill can be considered for its high efficiency, reliability, and low cost.

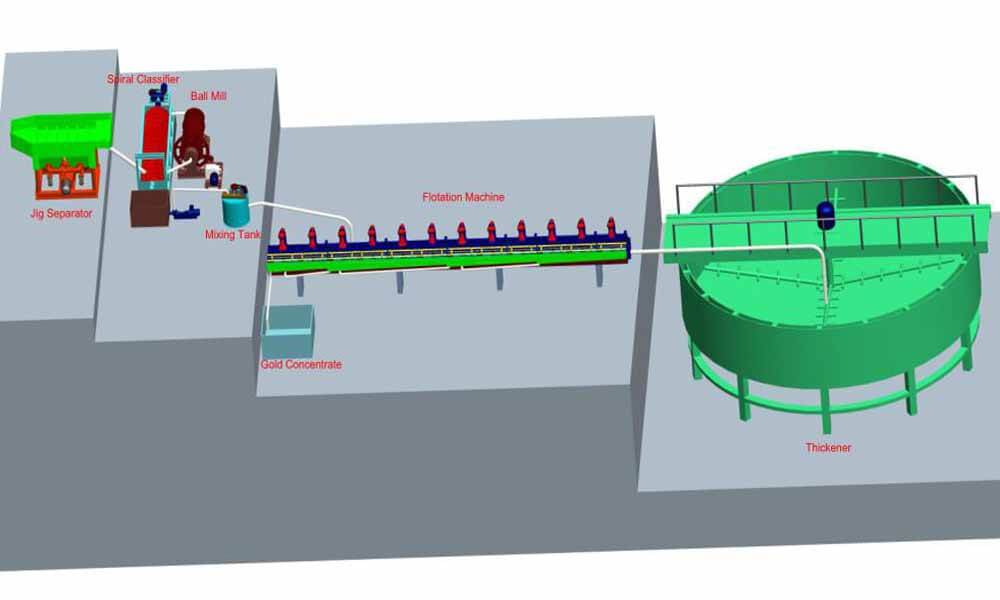

♦ Rock gold gravity separation plant

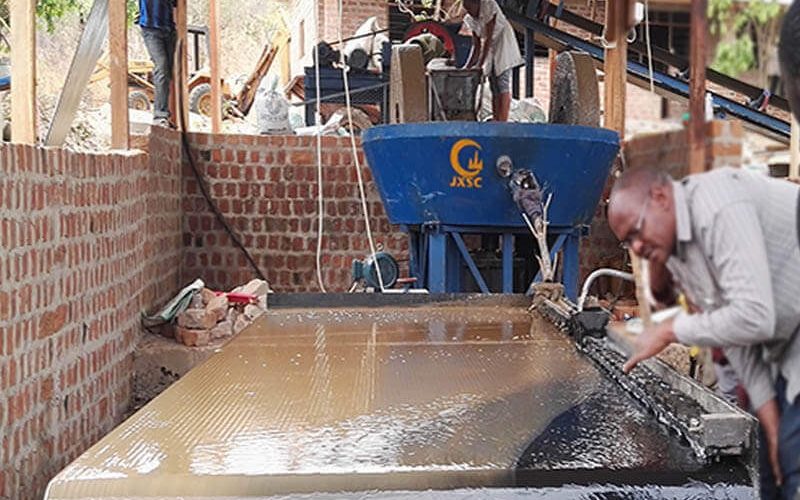

This is a complete set of 5TPH rock gold gravity separation line successfully customized by JXSC for customers in Cote d’Ivoire.

1. Feeding & Crushing: Raw materials enter the hopper through an excavator or forklift, and are evenly fed through a belt conveyor to the jaw crusher for primary crushing. The crushed materials enter the hammer crusher again through the belt conveyor for secondary crushing.

2. Gravity separation: Next, it is transported by the belt to the centrifugal concentrator for primary gold ore enrichment. The concentrate from the centrifuge enters the shaking table again for enrichment to obtain the final gold concentrate.

Hard rock gold processing plant for sale

Custom Rock Gold Solutions

0:54

4:01

2:12

5:21

6:11

This setup is a 20tph rock gold crushing plant, mainly comprising a coarse jaw crusher, a fine jaw crusher, four sets hammer crushers, and gravity separators.

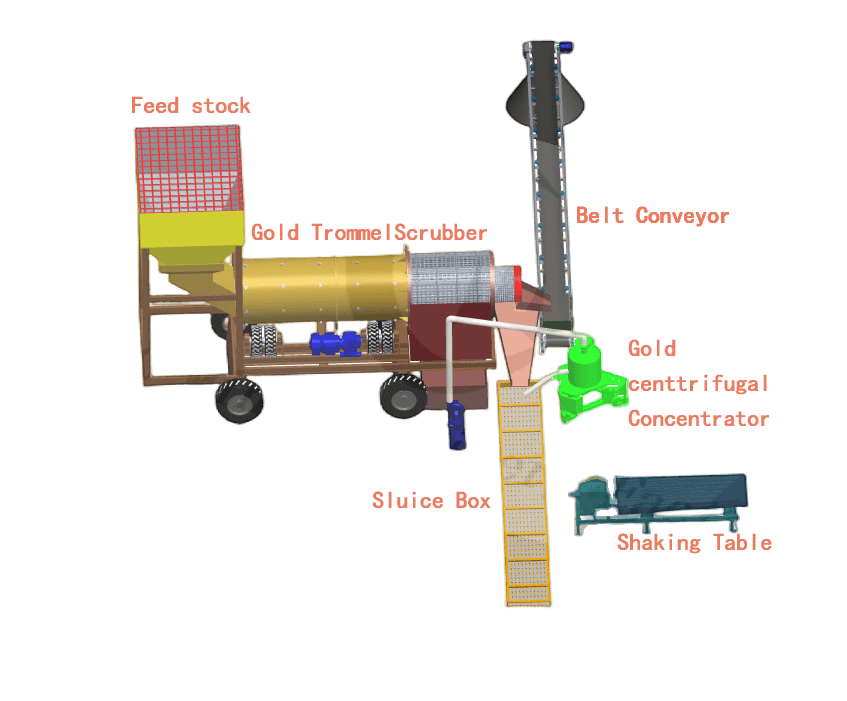

This setup is a 10tph alluvial gold and a 5tph rock gold mixed processing plant. Mainly has jaw crusher, hammer crusher, ball mill, spiral classifier, trommel scrubber, centrifugal concentrator, shaking table, and sluice box.

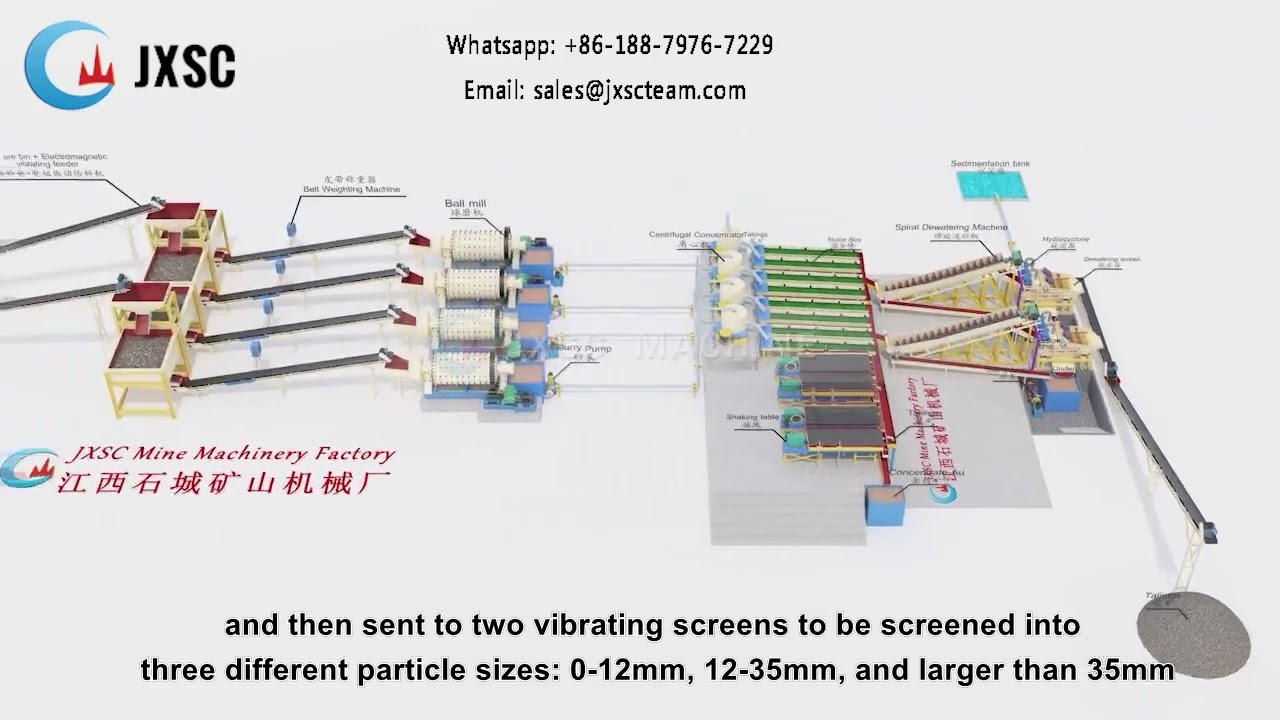

This is a flowchart of a 250TPH rock gold processing plant, mainly including jaw crusher, cone crushers, double roll crushers, ball mills, centrifugal concentrators, shaking tables, sluice boxes, spiral dewatering machines, and dewatering screen.

This setup is one complete 240TPD (tons per day) rock gold CIL plant flowchart, including feeding, crushing system, grinding system, gravity separation, leaching process, activated carbon adsorption process, gold-loaded carbon desorption, and electrolytic stage.

This setup is a 120TPD rock gold gravity separation + CIP plant, including feeding, crushing, grinding, gravity separation, leaching process, activated carbon adsorption process, gold-loaded carbon desorption and electrolytic stage, and tailing water recycle system..

small scale rock gold process plant - High Recovery & Low Cost Solutions

JXSC plant is mainly centered around “efficient dissociation – precise sorting – low-consumption operation”. It pays more attention to “adapting to local conditions”: it can process rock gold (such as sulfide ore) and alluvial gold; also supports mainstream processes such as gravity sorting and flotation, and can also combine chemical leaching (such as CIP/CIL process) to improve the recovery rate. Custom modular designs, proven process flow, and cost-saving equipment for small-medium hard rock gold extraction.

JXSC provides a complete set of gold processing solutions (flotation, CIP, CIL process, etc) and equipment according to specific mine production needs. The core function is to separate and enrich gold minerals in the raw ore into gold concentrate or finished gold through crushing, grinding, sorting, purification, and other processing steps. We also support customize small rock gold process plants with small investments, flexible and quick results.

Other Gold Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.