Mineral Processing » Solutions » Sand Making plant

Sand Making plant

Capacity: 30-1000TPH / Customizable

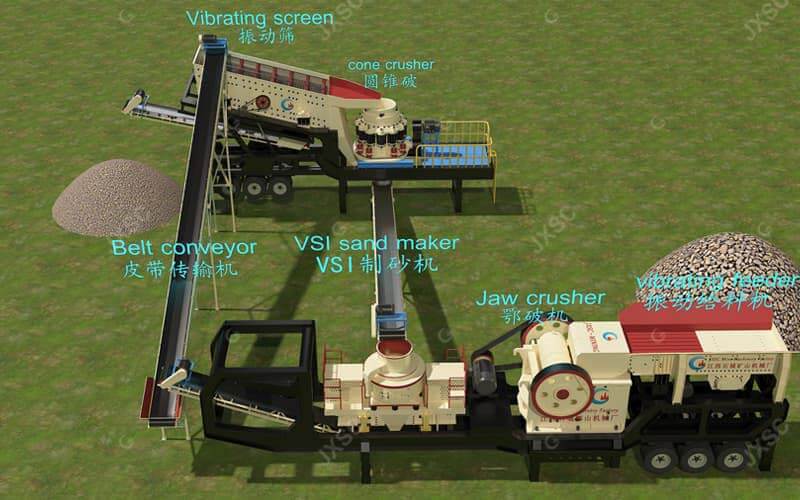

Main Equipment: feeder, crusher, sand making machine, vibrating screen, belt conveyors

Application material: Sand making production line for crushing and screening limestone, marble, granite, basalt, cobble, andesite, river stone, dolomite, bluestone, iron ore, and other materials to produce building aggregates with various particle sizes.

Application fields: It’s widely used in sand, rock, aggregate factories, mining, machine-made sand and gravel plant, construction and other industries.

Types Of Sand Making plant

A sand making plant is the full equipment used to produce artificial sand and gravel materials. It can efficiently crush, shape and screen raw materials into required sizes. Its sand making system combines various machines such as vibrating feeders, jaw crushers, cone crushers, impact crushers, sand making machines, vibrating screens, sand washing machines, belt conveyors, etc.

Each step ensures only cost-effective solutions for producing high-quality sand, from feeding and crushing to screening and shaping. Sometimes, washing, dehydration, and filtration can be performed after screening to obtain the most advantageous sandy finished product. It can be flexibly used for making sand from various materials, and JXSC will flexibly configure the fixed and mobile-type equipment according to specific project needs.

Features of sand making plant

- JXSC’s state-of-the-art equipment ensures superior quality and efficiency in sand production.

- Features energy-saving technology that reduces power consumption while maintaining productivity.

- The production line is highly adaptable and automated, crushing, screening and shaping rocks/minerals into consistent sizes without manual intervention.

- This sand making system can produce sand of various specifications, and we support customized sand making equipment.

Sand Making Plant Process

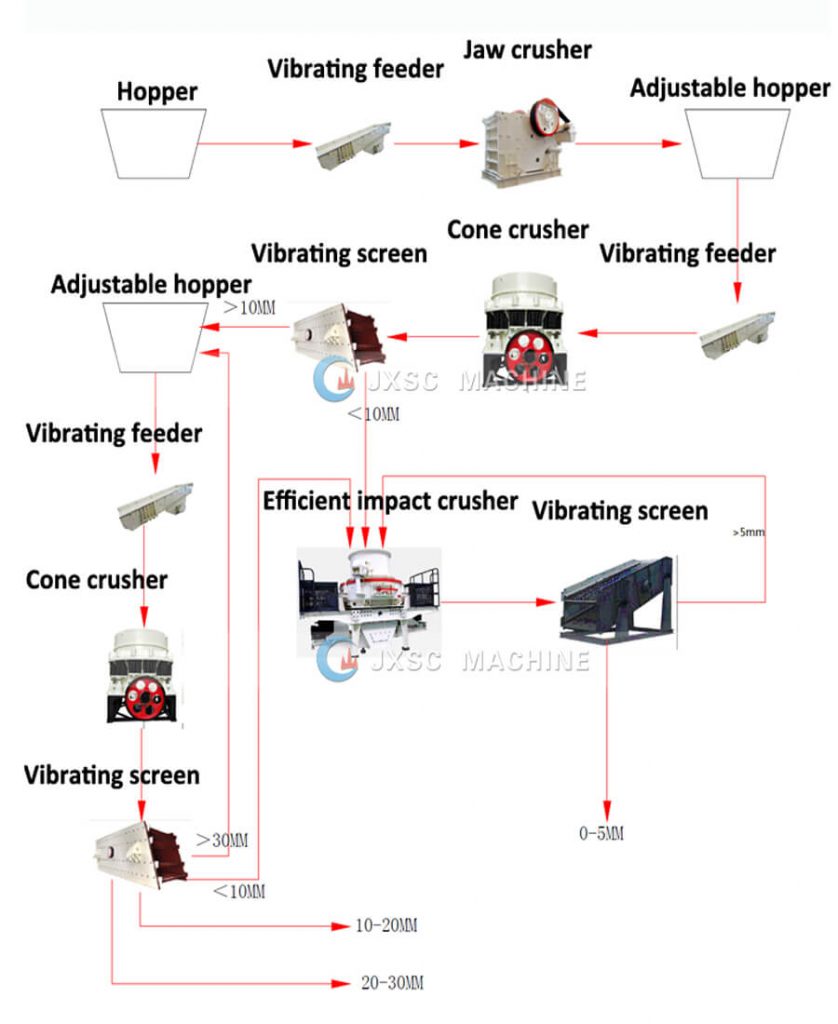

The sand making production line process consists of multiple stages, including feeding-crushing-sand making-screening, to produce high-quality sand for various applications.

1. Feeding Process

Feed large rocks or stones into the vibrating feeder to ensure uniform material delivery.

2. Crushing Process

The feeder distributes the material evenly to the jaw crusher, breaking it into smaller pieces. A cone crusher or impact crusher further finely crushes the crushed materials. Stone crushers apply enough force to break the material into smaller sizes.

3. Sand making (shaping) Process

- A cone crusher is used to crush finer sand and further shape smaller particles;

- The VSI crusher efficiently produces cubic sand and high-quality sand with the required properties due to its uniformity and strength.

This stage improves the shape and size distribution of the particles, ensuring optimal performance in various applications such as construction or concrete production.

4. Screening Process

The vibrating screen separates materials of multiple sizes at one time; fully meeting customers’ specific size needs.

5. Washing & dewatering process

If necessary, adding a wash or dewater process to remove impurities, water and achieve high cleanliness.

In sand making plants, the screening process can be used in multiple stages, which can better control the particle size and particle shape of the product, thereby improving the quality of products. JXSC sand-making production line uses carefully designed equipment to ensure consistent particle size distribution and excellent particle shape, meeting the strict requirements of construction projects.

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.